NZQA unit standard 26006 version 2

advertisement

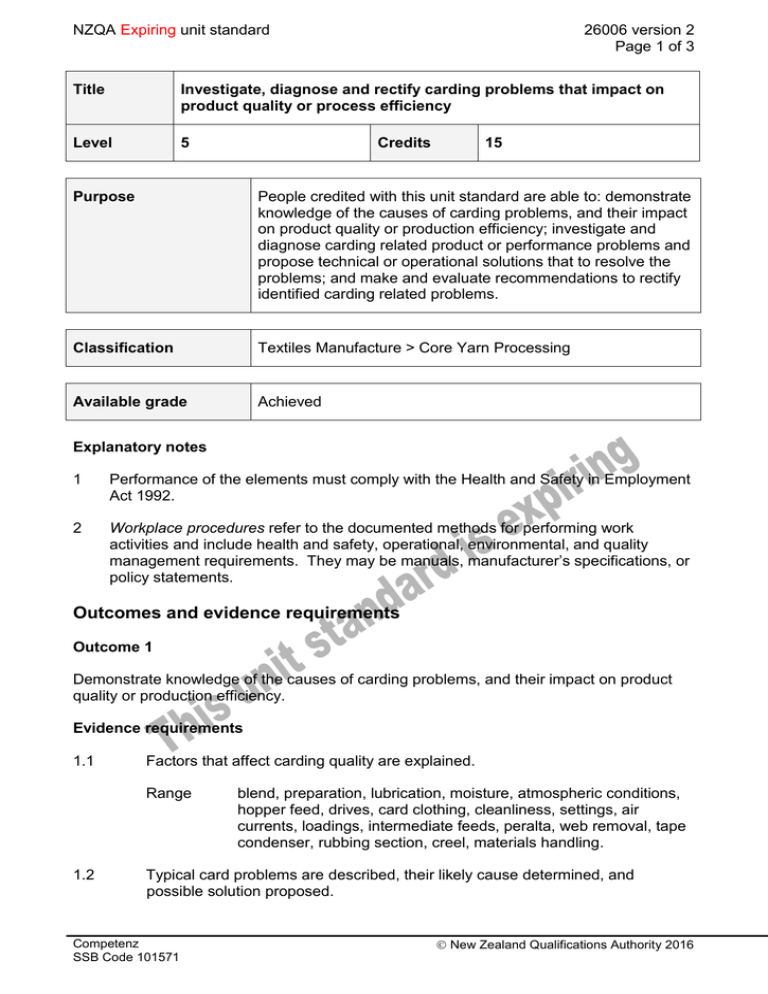

NZQA Expiring unit standard 26006 version 2 Page 1 of 3 Title Investigate, diagnose and rectify carding problems that impact on product quality or process efficiency Level 5 Credits 15 Purpose People credited with this unit standard are able to: demonstrate knowledge of the causes of carding problems, and their impact on product quality or production efficiency; investigate and diagnose carding related product or performance problems and propose technical or operational solutions that to resolve the problems; and make and evaluate recommendations to rectify identified carding related problems. Classification Textiles Manufacture > Core Yarn Processing Available grade Achieved Explanatory notes 1 Performance of the elements must comply with the Health and Safety in Employment Act 1992. 2 Workplace procedures refer to the documented methods for performing work activities and include health and safety, operational, environmental, and quality management requirements. They may be manuals, manufacturer’s specifications, or policy statements. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of the causes of carding problems, and their impact on product quality or production efficiency. Evidence requirements 1.1 Factors that affect carding quality are explained. Range 1.2 blend, preparation, lubrication, moisture, atmospheric conditions, hopper feed, drives, card clothing, cleanliness, settings, air currents, loadings, intermediate feeds, peralta, web removal, tape condenser, rubbing section, creel, materials handling. Typical card problems are described, their likely cause determined, and possible solution proposed. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard Range 26006 version 2 Page 2 of 3 problems must be relevant to the product range and processing equipment in the workplace and may include problems resulting in irregular yarn count, lumpy yarn, cloudy web, neps, thick and thin yarn. Outcome 2 Investigate and diagnose carding related product or performance problems and propose technical or operational solutions to resolve the problems. Range five different problems occurring in the workplace that have a significant impact on product or process performance. Evidence requirements 2.1 Investigation defines the problem, and identifies potential causative factors. Range identify problem, select and plan appropriate method of diagnosis. 2.2 Diagnosis confirms the causative factors and enables recommendation of solutions. 2.3 Documentation describes the investigation process and supports the diagnosis of causative factors. Outcome 3 Make and evaluate recommendations to rectify identified carding related problems. Range recommendations are proposed and evaluated for two specific carding related problems encountered in the workplace. Evidence requirements 3.1 Recommendations are appropriate and relevant to the identified problem. 3.2 Recommendations are trialled and assessed to determine effectiveness in rectifying the problem. 3.3 Final solution is identified and documented in terms of workplace procedures. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 20 November 2009 31 December 2019 Review 2 19 May 2016 31 December 2019 Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 26006 version 2 Page 3 of 3 Consent and Moderation Requirements (CMR) reference 0030 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016