NZQA unit standard 26001 version 2

advertisement

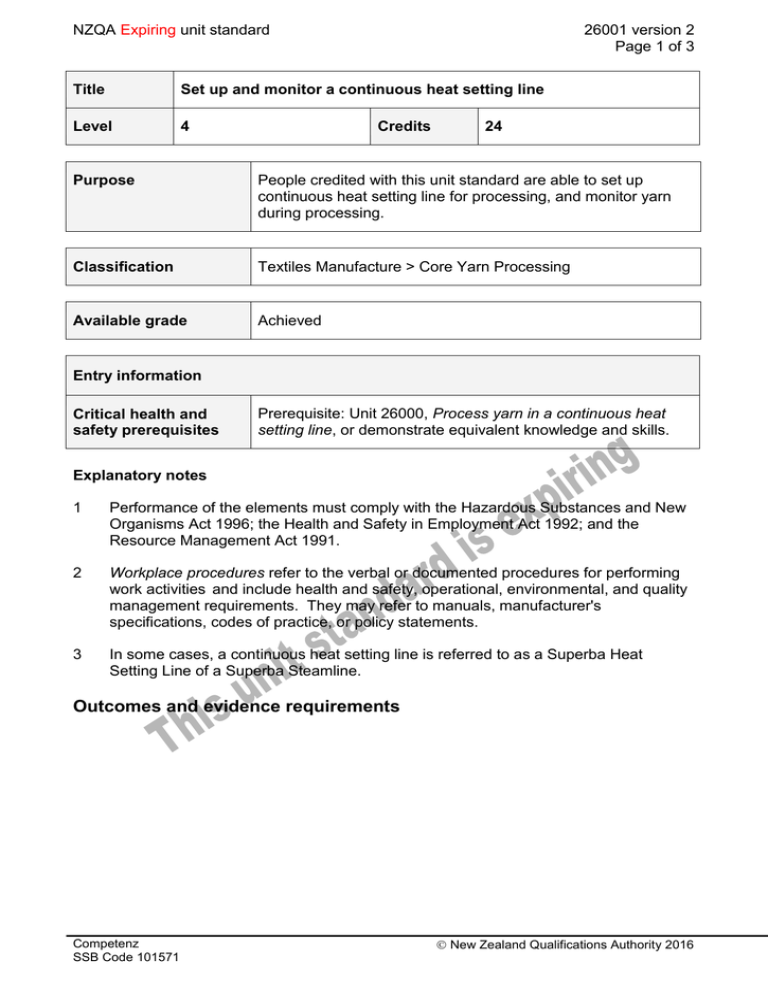

NZQA Expiring unit standard 26001 version 2 Page 1 of 3 Title Set up and monitor a continuous heat setting line Level 4 Credits 24 Purpose People credited with this unit standard are able to set up continuous heat setting line for processing, and monitor yarn during processing. Classification Textiles Manufacture > Core Yarn Processing Available grade Achieved Entry information Critical health and safety prerequisites Prerequisite: Unit 26000, Process yarn in a continuous heat setting line, or demonstrate equivalent knowledge and skills. Explanatory notes 1 Performance of the elements must comply with the Hazardous Substances and New Organisms Act 1996; the Health and Safety in Employment Act 1992; and the Resource Management Act 1991. 2 Workplace procedures refer to the verbal or documented procedures for performing work activities and include health and safety, operational, environmental, and quality management requirements. They may refer to manuals, manufacturer's specifications, codes of practice, or policy statements. 3 In some cases, a continuous heat setting line is referred to as a Superba Heat Setting Line of a Superba Steamline. Outcomes and evidence requirements Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 26001 version 2 Page 2 of 3 Outcome 1 Set up continuous heat setting line for processing. Evidence requirements 2.1 Continuous heat setting line is prepared for operation in accordance with workplace procedures. Range yarn identified, creel loaded, tension devices, thread up of creel, accumulator and yarn combing, frieze or yarn preparation system, coiler speed, belt speed, pre-steamer and cooler, heat setting tunnel, winder speed, cone length, cone magazines. Outcome 2 Monitor yarn during continuous heat setting line processing. Evidence requirements 3.1 Process conditions are monitored and maintained during processing in accordance with workplace procedures. 3.2 Samples are taken and tests carried out in accordance with workplace procedures. 3.3 Test results are assessed and machine and chemical adjustments made to achieve product quality in accordance with workplace procedures. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 20 November 2009 31 December 2019 Review 2 19 May 2016 31 December 2019 Consent and Moderation Requirements (CMR) reference 0030 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 26001 version 2 Page 3 of 3 Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016