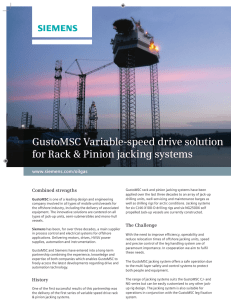

The electrical variable-speed rack-and-pinion jacking system

advertisement

The electrical variable-speed rack-and-pinion jacking system Enhancing efficiency on jack-up rigs with an alternative to conventional hydraulic systems © Siemens AG 2015. All rights reserved. Design (1) Jacking systems Each jacking unit driven by electric motors to drive input / output planetary gearboxes and special designed 7 teeth pinions. Certification The jacking systems can be delivered with certificates from recognized Classification Societies such as ABS, DNV, Lloyds. © Siemens AG 2015. All rights reserved. Design (2) Pinion load is controlled by the system, not depending on special slip-motor Reduced wear on the rack Control system holds platform until all brakes are lifted Avoid high pinion load, Speed is reduced to zero before brakes are applied Avoid brake wear Jacking system integrated into the jacking structure Reduce critical stress levels Reduced dimensions Improved constructability and torsional stiffness © Siemens AG 2015. All rights reserved. Avoid brake slipping Design (3) • No overdesign • High accuracy of load sharing over the pinions • Less power and less cooling capacity required • Integrated rack phase difference monitoring • Redundancy, reliability, availability © Siemens AG 2015. All rights reserved. Results • High-speed jacking from 0.45 to 1.8 m/min • Durable by optimized load sharing over the pinions = Less wear in gearbox / pinions • Emergency operation possible when facing reduced power • Accurate and integrated leg position indication and RPD safeguarding • Redundant control system • Use of standardized materials • No need for special motors with high-slip requirements © Siemens AG 2015. All rights reserved. Not only drilling rigs ! © Siemens AG 2015. All rights reserved. Major clients: Major clients: • CMHI • JURONG • DALIAN SIOC • SAMSUNG • LAMPRELL • DDWPaxocean Major clients: • Seadrill • Statoil • Bestford Capital • Noble Drilling • TS Drilling • COSL • Seajacks number 35 30 25 20 15 10 5 0 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 Scope Siemens includes delivery of gear boxes Siemens IND MD (formerly Flender) © Siemens AG 2015. All rights reserved. Scope of supply Siemens • Siemens will engineer and deliver the electrical and control systems to drive the pinions that will lower and raise the platform. • The automation scope consists PCS7 hardware / software, fully tested at our workshop in Zoetermeer. The drives & motors consist of standard materials with customer specific modifications and offshore ratings. © Siemens AG 2015. All rights reserved. Technical characteristics Separate safety layers: • 1) over speed • 2) brake release • 3) motor control Precise load sharing over the pinions = less wear and tear 0,0 m/min is a controlled state = pre-torque without manual intervention Multi layer safety= low power availability, jacking operation (up or down) continued. Rack Phase Difference monitoring (cm’s) © Siemens AG 2015. All rights reserved. Differences (1) Increased availability by “layer concept”. In case of limited power supply, jacking will still be possible by decreasing the jacking speed: There is a choice to operate the system with reduced performance when a complete layer fails © Siemens AG 2015. All rights reserved. Differences (2) Load is always shared equally across the motors/pinions per leg. There are no step changes in the load or torque on the system. Smooth raising and lowering of the platform. Load 1 Chord Speed 1 Chord © Siemens AG 2015. All rights reserved. Differences (3) Ease of operation • Operability: speed and precise control of the leg handling. • Operator control via joysticks, pushbuttons and two touch screens (one man show). • Status and set point interface is via a dedicated HMI located in the central control desk. • Ultimate limit switches and over speed switches protect the system from inadvertent operational errors. © Siemens AG 2015. All rights reserved. Differences (4) : Enhanced safety Safeguarding: Each leg is equipped with an over-speed switch. This is a dominant safeguarding loop (SIL 2 design): if non-energized, an over speed switch generates a full stop in any mode of operation. Continuous autonomous control functions: Drive control and control of brakes are done by the autonomous control system which means that the system won’t be able to release its brakes in case operations are not determined as being “healthy”. We achieve this by means of: • the continuous measurement of input variables • the continuous control of output values © Siemens AG 2015. All rights reserved. We are happy to answer your questions! © Siemens AG 2015. 2013. All rights reserved.