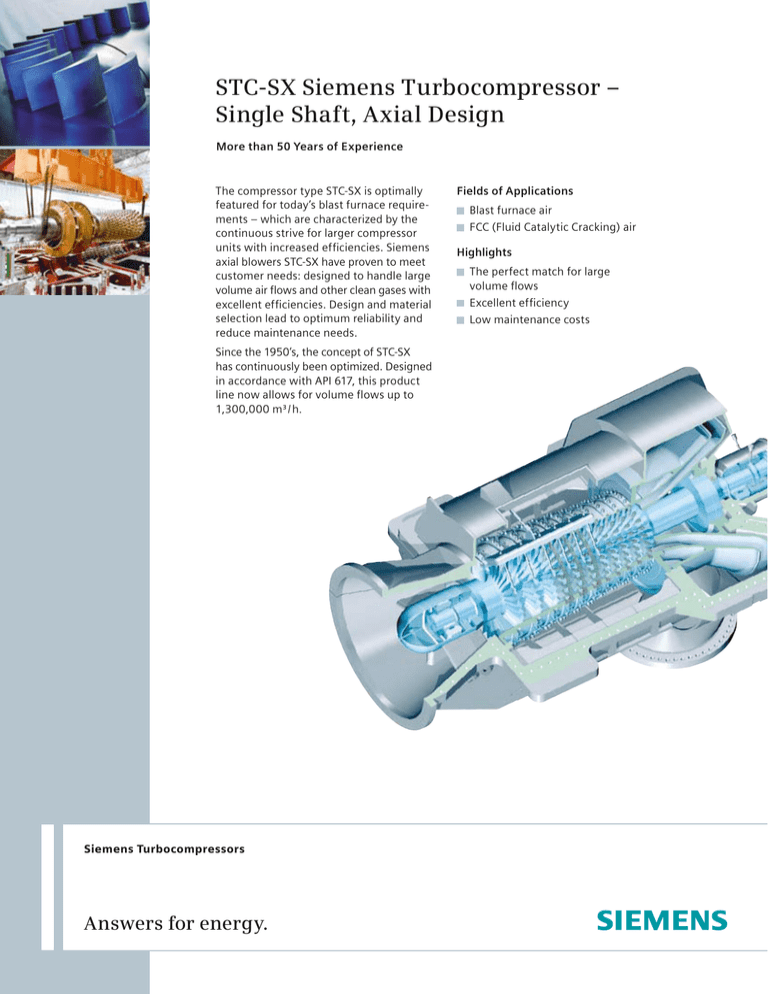

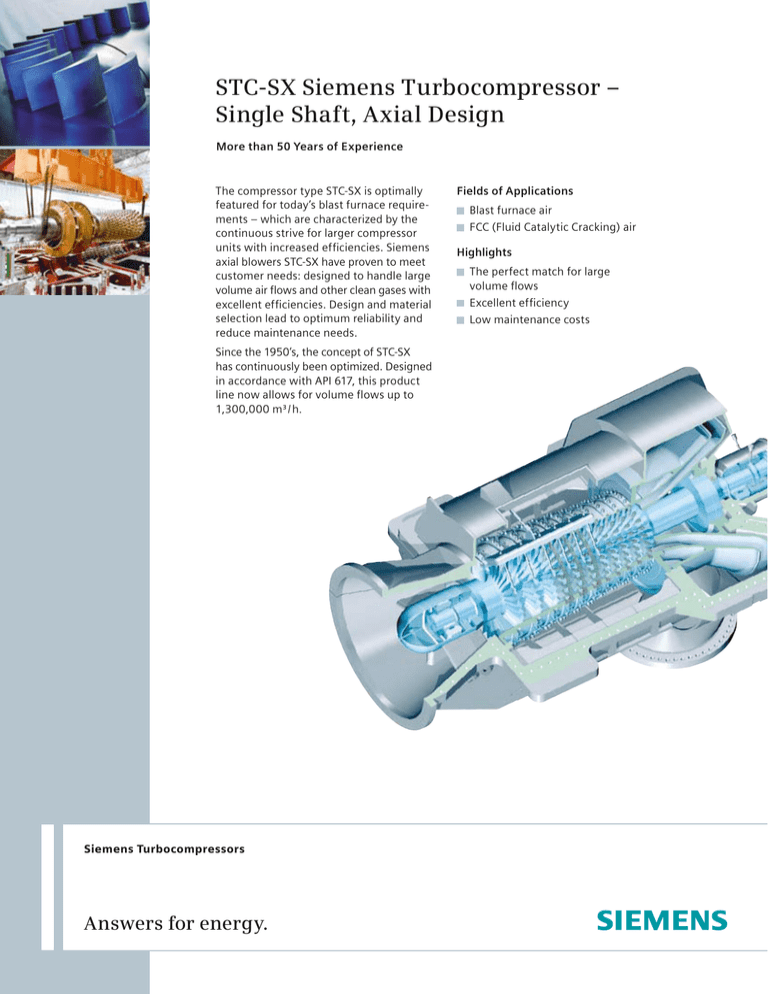

STC-SX Siemens Turbocompressor –

Single Shaft, Axial Design

More than 50 Years of Experience

The compressor type STC-SX is optimally

featured for today’s blast furnace requirements – which are characterized by the

continuous strive for larger compressor

units with increased efficiencies. Siemens

axial blowers STC-SX have proven to meet

customer needs: designed to handle large

volume air flows and other clean gases with

excellent efficiencies. Design and material

selection lead to optimum reliability and

reduce maintenance needs.

Since the 1950’s, the concept of STC-SX

has continuously been optimized. Designed

in accordance with API 617, this product

line now allows for volume flows up to

1,300,000 m³ / h.

Siemens Turbocompressors

Answers for energy.

Fields of Applications

Blast furnace air

FCC (Fluid Catalytic Cracking) air

Highlights

The perfect match for large

volume flows

Excellent efficiency

Low maintenance costs

Design Concept

High Flow Rates at High Efficiencies

Modular Principle

Designed for large volume air flows and

other clean gases over a wide operation

range, STC-SX blower series guarantee

excellent efficiency. With their low powerconsumption, Siemens turbocompressors

optimize a plant’s energy balance.

The design principle common to the STC-SX

series is a modular concept. It is based on

finely graded machine elements and flow

components that have proven their reliability over many years of operation. A great

variety of casing sizes and blade sizes

allows for tailor-made design according

to individual specifications. Depending on

the volume flow and the necessary pressure

ratios, the size of the flow components and

the number of stages are chosen from the

construction kit. Implementing reliable components lead to high flexibility in order to

meeting process requirements.

Casings have an axial or radial inlet, minimizing flow loss. As standard, they are

fabricated. On special request, Siemens

also offers cast casings. These machines

are typically uncooled straight-through

blowers, optimal for high discharge

temperatures.

STC-SX

Electric-motor-driven axial blower STC-SX for an FCC plant.

Rotor assembly of an axial

blower at the Duisburg

manufacturing site.

Highlights

Tilting pad bearing for journal

and axial thrust bearing

Up to 19 stages

Improved efficiency due to new

blading technology

Rotor blades of first and second

stage are made of duplex steel

Corrosion resistance due to unique

material usage

Control Systems

Broad range of appropriate

control systems

- Performance control

- Independent anti-surge protection

- Anti-choke control

Control by either speed variation

or adjustable guide vanes, or a

combination of both

Remote Monitoring System (RMS)

for preventive maintenance and

optimum performance

Technical Data

Flow rates from 50,000 to 1,300,000 m³ / h

(30,000 to 825,000 cfm)

Pressure ratio between 1.9 and 6.0

Speed up to 9,000 rpm

Discharge temperature up to 350 °C

Various control systems to optimize operation

Driver: electric motor or steam turbine,

depending on process and energy resources

Benefits

Combining reliable technology with innovative development,

Siemens STC-SX axial flow compressors guarantee benefits that

optimize your business.

Compression of large volume flows

Highest degree of efficiency

Extended operating range

Modular and robust machine design

High quality due to proven components and API standards

Prevention of wear due to optimized material selection

Low operating and maintenance costs

Service and maintenance work at the rotor of a blast

furnace blower.

Application Range

STC-SX is the perfect match for volume flows

up to 1,300,000 cubic meters per hour. The axial

blower realizes pressure ratios up to 6.

Speed

U /min

p/p

9,000

8

8,000

7,000

Pressure ratio

6

6,000

5,000

4

4,000

3,000

2

70

100

150

250

350

450

600

1,000

1,300

2,000

1,000

0

50 70

100

200

300

500

700

1,000

V x 1,000 m3 /h

Published by and copyright © 2008:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens AG

Energy Sector

Oil & Gas

Wolfgang-Reuter-Platz

47053 Duisburg, Germany

Siemens Energy Inc.

10730 Telge Road

Houston, Texas 77095, USA

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail: support.energy@siemens.com

www.siemens.com / energy

Oil & Gas Division

Order No. E50001-G420-A111-X-4A00

Printed in Germany

Dispo 05400, c4bs

1388, 4497 S WS 11083

Printed on elementary chlorine-free

bleached paper.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its

affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical

options available, which may not apply in

all cases. The required technical options

should therefore be specified in the contract.