Installation of state-of-the-art

I&C system with minimal downtime

safeguards water supply

Reference – Control System

Instrumentation, Controls & Electrical

SPPA-T3000 Control System

replaces the old I&C system of the Yanbu power

and desalination plant. This guarantees high

availability levels, thus also safeguarding water

supply.

The Result

■ Modernization of the I&C

systems coupled with

minimized downtime

thanks to first-class project

management

■ High availability levels

thanks to a state-of-the-art,

reliable control system with

user-friendly operation

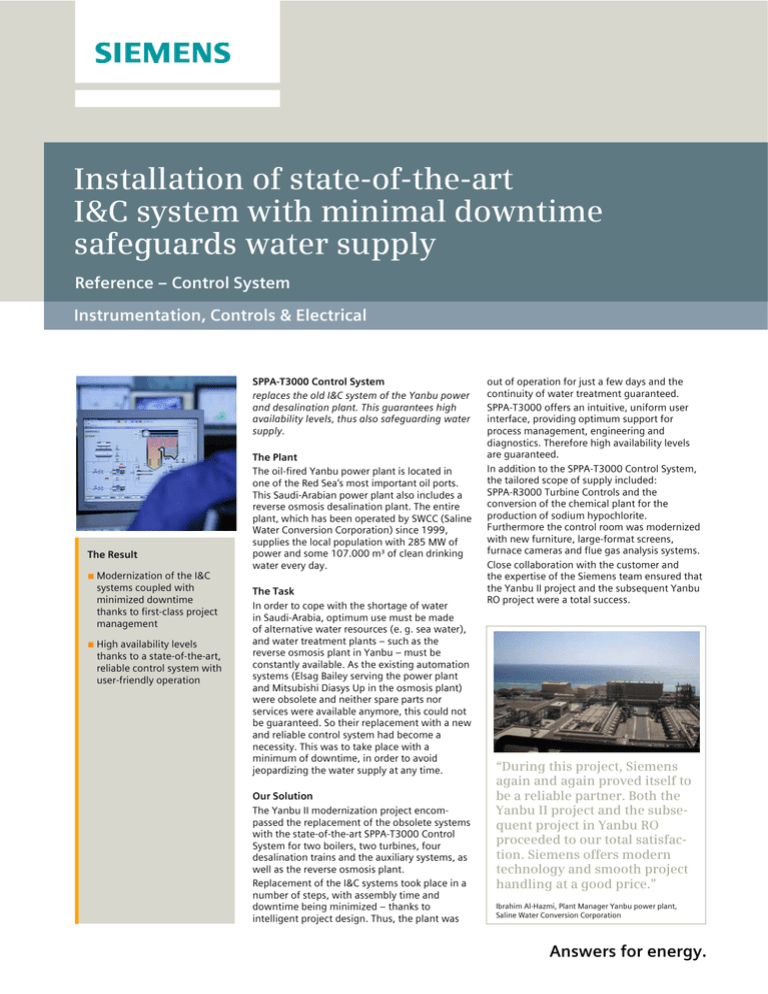

The Plant

The oil-fired Yanbu power plant is located in

one of the Red Sea‘s most important oil ports.

This Saudi-Arabian power plant also includes a

reverse osmosis desalination plant. The entire

plant, which has been operated by SWCC (Saline

Water Conversion Corporation) since 1999,

supplies the local population with 285 MW of

power and some 107.000 m³ of clean drinking

water every day.

The Task

In order to cope with the shortage of water

in Saudi-Arabia, optimum use must be made

of alternative water resources (e. g. sea water),

and water treatment plants – such as the

reverse osmosis plant in Yanbu – must be

constantly available. As the existing automation

systems (Elsag Bailey serving the power plant

and Mitsubishi Diasys Up in the osmosis plant)

were obsolete and neither spare parts nor

services were available anymore, this could not

be guaranteed. So their replacement with a new

and reliable control system had become a

necessity. This was to take place with a

minimum of downtime, in order to avoid

jeopardizing the water supply at any time.

Our Solution

The Yanbu II modernization project encompassed the replacement of the obsolete systems

with the state-of-the-art SPPA-T3000 Control

System for two boilers, two turbines, four

desalination trains and the auxiliary systems, as

well as the reverse osmosis plant.

Replacement of the I&C systems took place in a

number of steps, with assembly time and

downtime being minimized – thanks to

intelligent project design. Thus, the plant was

out of operation for just a few days and the

continuity of water treatment guaranteed.

SPPA-T3000 offers an intuitive, uniform user

interface, providing optimum support for

process management, engineering and

diagnostics. Therefore high availability levels

are guaranteed.

In addition to the SPPA-T3000 Control System,

the tailored scope of supply included:

SPPA-R3000 Turbine Controls and the

conversion of the chemical plant for the

production of sodium hypochlorite.

Furthermore the control room was modernized

with new furniture, large-format screens,

furnace cameras and flue gas analysis systems.

Close collaboration with the customer and

the expertise of the Siemens team ensured that

the Yanbu II project and the subsequent Yanbu

RO project were a total success.

“During this project, Siemens

again and again proved itself to

be a reliable partner. Both the

Yanbu II project and the subsequent project in Yanbu RO

proceeded to our total satisfaction. Siemens offers modern

technology and smooth project

handling at a good price.”

Ibrahim Al-Hazmi, Plant Manager Yanbu power plant,

Saline Water Conversion Corporation

Answers for energy.

Published by and copyright © 2013:

Siemens AG, Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

For more information contact

sppa-t3000.energy@siemens.com

www.siemens.com/energy/sppa-t3000

Siemens Energy, Inc.

Instrumentation, Controls, & Electrical

1345 Ridgeland Parkway, Suite 116

Alpharetta, GA 30004, USA

T3_FR_Yanbu_e_V1-0

Order no. E50001-G230-A340-X-4A00

Printed in Germany

Dispo 05401, c4bs-Nr. 7465

Printed on elementary chlorine-free

bleached paper.

Unrestricted

AL:N ECCN:N

All rights reserved.

Trademarks mentioned in this document are

the property of Siemens AG, its affiliates, or

their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.