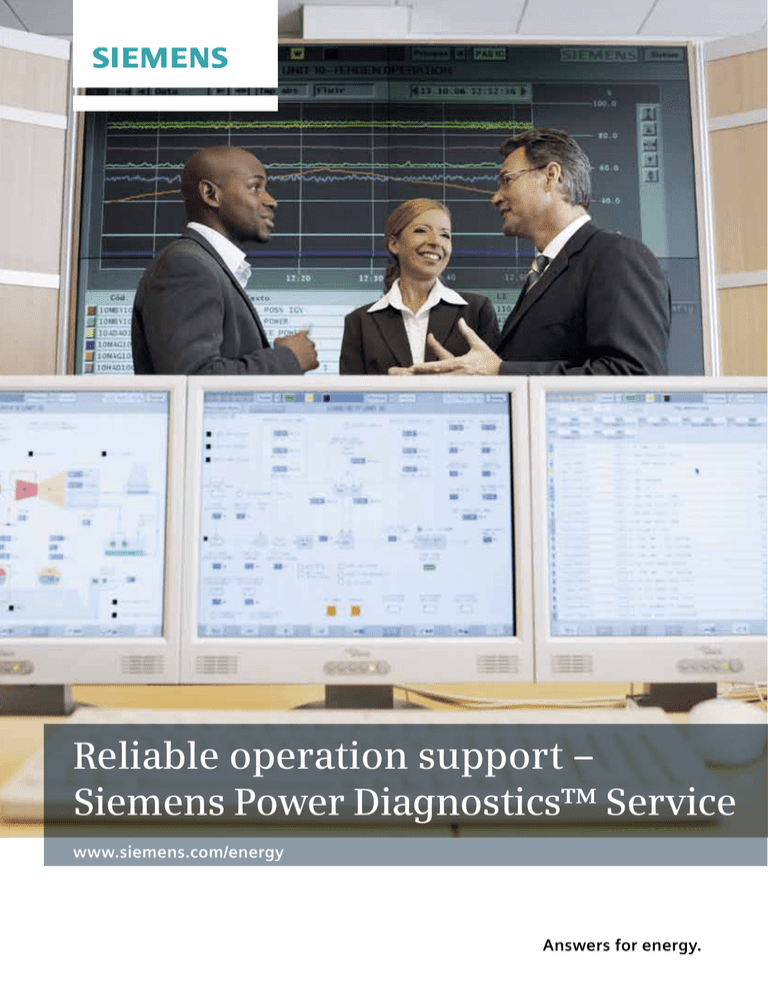

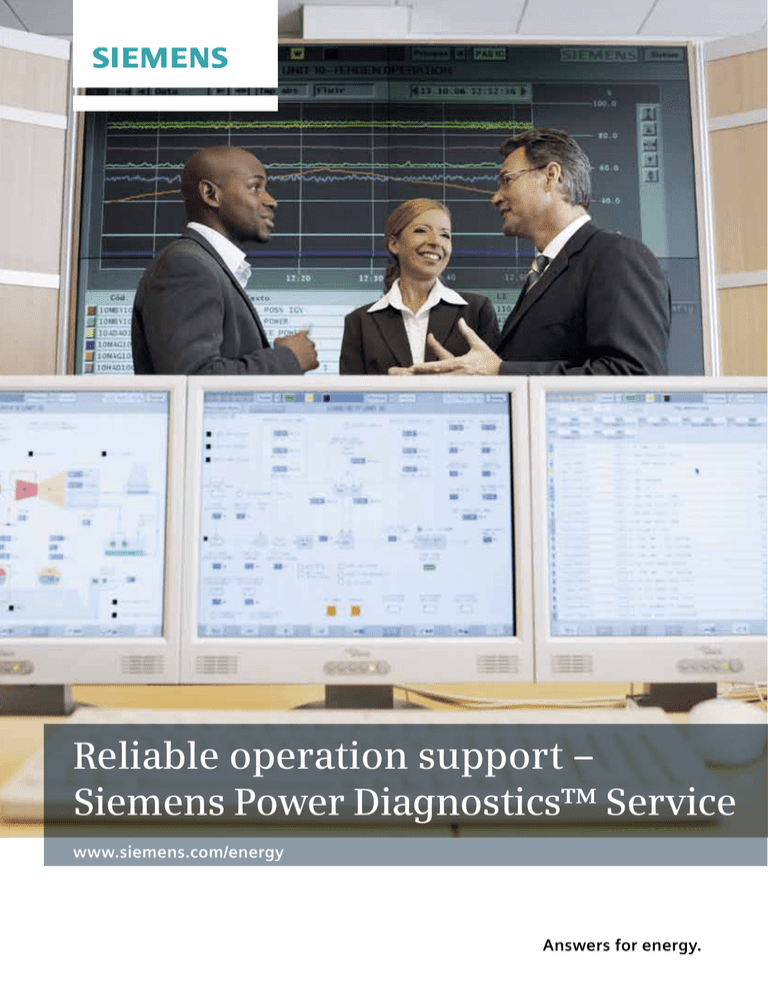

Reliable operation support –

Siemens Power Diagnostics™ Service

www.siemens.com/energy

Answers for energy.

Long-term cooperation between customers and Siemens

First monitoring center in Orlando

At your service:

Siemens Power Diagnostics

In the last decade and following market developments, the business relationships between

customers and original equipment manufacturers (OEMs) of power plants have shifted

­toward longer-term cooperation. This is particularly due to the rapid development of highefficiency components, for example gas turbines, using the most advanced technologies

and materials. The more sophisticated a power plant component becomes, the more attention is required during operation to avoid the risk of abnormal behavior. This conclusion has

led to new forms of cooperation between customers and OEMs. Siemens Power Diagnostics™

Service is one important outcome of this development.

A new level of cooperation

With new high-performance equipment being introduced

in the market, customers require Operation and Maintenance (O&M) programs and Long-Term Programs (LTP).

These programs are designed to cover the greater part of

the equipment lifetime or the entire combined-­cycle plant

‒ occasionally even including some risk-sharing of certain

repair costs with an OEM.

2

With both types of programs, customers are able to better

plan operational costs during the service program period.

At the same time, the boost in information technology

­facilitates the secure transfer of large amounts of data

over long distances – thus enabling the OEM to use

­remote monitoring to help customers detect a possible

­impending operational problem. This can minimize

­unplanned outages and maximize power generation

­availability.

Your power plant

Power Diagnostics

center

Expert

network team

Use of advanced

diagnostic tools and

techniques for

■■ Monitoring of

­machine conditions

■■ Collecting and

­processing of data

■■ Analysis of limit

values and ­deviation

from normal

behavior

Engineering

­know-how

■■ Interpretation and

diagnostics

■■ Data assessment

■■ Development of

recommendations

for future operations,

repairs, and

­modernizations

Reports

Access

Info

Analysis

Monitoring

Offline diagnostics

Online diagnostics

Power Diagnostics Service is backed

by vast field experience.

Multiple advantages of Power Diagnostics Service

Services made-to-order

Based on decades of experience in ­diagnostics, Siemens

opened a pilot remote monitoring center in Orlando, Florida

in 2000, launching a new ­quality standard in remote

­monitoring of advanced gas turbine and combined-cycle

plants for long-term service program customers. With the

primary focus on these long-term maintenance programs,

monitoring on a 24/7 basis was officially introduced in

February 2002 as “Power Diagnostics Service” (PDS).

The PDS goal is to detect abnormal operating conditions

of power plant equipment like gas turbines, steam

­turbines, heat recovery boilers, and generators as early

as possible in order to subsequently help improve plant

availability and operations. To this end, multiple data

­acquisition tools are used to obtain daily operational data

from our customers’ plants.

data collection and analysis. In other words, there is no

possibility of controlling the site’s instrumentation and

­control system and engine operation. This means that PDS

is not operating customers’ power plants, but helping

them run the equipment more efficiently and profitably.

This service is backed by field experience gained from

more than 400 installations of high-efficiency gas turbines

and other equipment, an advantage only the OEM can

­offer. For this reason, Power Diagnostics is a special

­service offered to Siemens customers.

Aided by advanced diagnostic software, experienced

­diagnostic engineers can identify issues before they reach

conventional alarm levels. If necessary, these engineers

can be supported by specialists throughout the entire

­Siemens Energy organization.

Monitoring and supporting, but not operating

As a leading supplier of power plants, we are aware of

many of the s­ ecurity challenges concerning the operation

of our c­ ustomers’ plants. Siemens PDS is based on passive

Operation and maintenance by Siemens for a Philippine power plant

3

PDS may help you turn a potential forced

outage into a scheduled event.

PDS is designed to support your management

­decisions on consistent refurbishment.

The O&M power plant in Taiwan benefits

from PDS and won the 2008

­“Best ­Environmental Plant of the Year” award.

Winning in competitive markets

Unparalleled experience

Siemens has been at the forefront of power generation

for more than 140 years. Therefore, our Power Diagnostics

Service is based on experience unrivalled in the industry.

With PDS, higher reliability of your power plant is not left

to chance, but can be the consequence of a well thoughtout process of continuous data acquisition, data analysis,

diagnosis and regular documentation of machine conditions. PDS is designed to provide a more reliable basis for

your management decisions regarding:

■■ scheduled outages

■■ performance and operating optimizations

■■ plant operating support

■■ consistent refurbishments

■■ timely reinvestments

4

Better use of scheduled outages

Cooperation between the customer and the OEM also

means that the units we monitor will be checked against

our ever-growing database of similar machines and components in the field. By doing so, we can help detect many

arising issues months before the Instrumentation and

Control system (I&C) would generate an alarm or even trip

the unit due to equipment protection criteria. With this

system in place, many issues can be planned for and

­addressed proactively during scheduled outages. In

­addition, with PDS your power plants are monitored using

highly advanced computing technology and algorithms

designed for the utmost security and quickest response.

Early fault detection allows sufficient time for service teams

to prepare parts and manpower, turning a potential forced

outage into a scheduled event, thus helping to keep

downtime to a minimum.

Higher reliability potential

Continued condition monitoring of your power station

can help you be an even more reliable partner for

your customers. In addition to helping you minimize the

risk of unplanned outages, you can use data from our

­Power Diagnostics Service to optimize the operation of

your units, while our regular condition reports can help

you assess the demand for future investments. They

may also help you to evaluate possible operational

­alternatives to cover special customer needs.

Opportunity for substantial cost savings

Our regular reviews and performance analyses can help

you operate your assets at higher efficiency levels. This

may result in substantial savings on fuel, machinery, and

enhance environmentally friendly operation.

PDS can also help you make decisions that can potentially

extend the lifetime of your power plants. Knowing more

about their condition may allow for a more precise risk

­assessment and a better perspective on their future

­performance.

You can choose a service program

­according to your needs.

Helping you minimize your operational risks

In combination with service programs, PDS can help you

minimize the operational risks of your assets. Depending

on the service program you select, we can offer a variety

of services that enable you to concentrate on your core

business while your assets are carefully monitored by our

experienced diagnostics and service engineers.

To make use of the full potential of Power Diagnostics

­Service, you can choose from customized service programs

like Operation and Maintenance programs and Long-Term

Service Programs. These can be designed to cover the

greater part of an engine’s target lifetime or, in the case

of an O&M, virtually the entire range of combined-cycle

power generation components. While Long-Term Service

Programs mainly cover periodic service and maintenance,

an O&M program also includes a broader range of S

­ iemens

services at your plant. This includes the daily operation of

the plant and a wide range of maintenance activities

which, based on our global long-term O&M experience

and our OEM expertise, can help continuously optimize

plant efficiency and availability. With these service offerings

featuring PDS, you can find the right combination for your

requirements, from a regular monitoring of your power

station, to a more detailed monitoring that includes trend

analysis, to actions such as assessing threshold deviation

from expected unit behavior.

PDS allows you to concentrate on your core business while your units are skillfully

monitored by our experienced diagnostics and service engineers.

5

A valuable experience: your success!

Our remote service centers feature expert knowledge for more than 400 gas turbine, steam turbine,

and generator installations as well as other power plant components all over the world. These are only

a few customer statements that underscore the benefits of Siemens Power Diagnostics Service.

What our customers say about Siemens Power Diagnostics Service:

»

»

Siemens fleet knowledge and

­record ­database is very helpful

and time-saving during an ­unusual

event and defect ­rectification.

«

Luckily, we don’t need this service often, but

when needed they have responded very quickly.

«

Modules for

Heat Recovery

Steam Generator

Gas Turbine

Generator

Steam Turbine

Turbo Train

Power Diagnostics Speciality Monitors are available

for all ­components of the energy conversion process.

Take advantage of upcoming planned outages to

implement the corrective measures identified remotely.

Dedicated modules for your success

Monitoring made-to-order

While each customer has his or her own service expectation, each power plant has specific requirements. To meet

your individual needs, Siemens has developed a system of

­dedicated modules for diverse tasks. These modules may

be adapted and fine-tuned to the application as required,

which can help you optimize operational costs.

To date, there are several distinct modules available in the

Power Diagnostics product lineup, each of them individually specialized in monitoring, analysis, and diagnosis:

■■ Vibration monitoring for steam turbines, gas turbines,

and generators

■■ Partial-discharge monitors for generators and

­high-­voltage components

■■ Diagnosis for water and hydrogen cooling circuits

in generators

■■ Dedicated rules for automated analysis and diagnosis

■■ Thermodynamic process monitoring

for ­entire ­power plants

Helping you make proactive decisions

For each module, Siemens can offer regular reporting and

information on the components’ status through special,

individualized service programs. With this condition

­monitoring capability, Power Diagnostics Service can offer

­additional information about your power plant.

This information supports a timely and detailed recognition

of many critical tendencies and changes in special operating

parameters. These Specialty Monitors can provide:

■■ Regular documentation of machine conditions

■■ Early detection of many operating issues

■■ Reliable information to help you make proactive decisions

■■ Fast access to the Siemens expert network

Optimized maintenance strategy

Using the results of our modules, you can prioritize and

optimize your maintenance resources according to the

­actual demand. In addition, better knowledge of the

­machine condition can help you operate your machines

more flexibly and may improve the overall efficiency,

availability and reliability of your power station.

In combination with a service program, Remote Monitoring

and Power Diagnostics Service can also open up new

oppor­tunities for incentive-based performance sharing

­between your company and Siemens.

Your access to support

Siemens Power Diagnostics installs and maintains a data

acquisition system at your site. The system is connected

to the Power Diagnostics Center (PDC) through a secure

common Remote Service Platform (cRSP) connection,

with a router and phone connection as backup.

8

Siemens Power Diagnostics features expert knowledge to support your plant operation around the clock

Berlin

Muelheim

Orlando

Erlangen

Ready when you need it ‒ around the clock and globally.

The PC-based data acquisition system is passively connected

to the control system via OPC, receiving data from the

I&C system and the Specialty Monitors along a one-way

data highway, with no feedback to the site’s I&C system.

At the PDC, the raw data is processed through Power

Monitor, an empirical ­system-modeling tool and an artificial ­intelligence rule base. Power Monitor is designed to

detect even subtle deviations in the analog sensors within

the variability of normal operation ‒ and well within the

existing control threshold alarm limits ‒ which can aid

in early recognition of ­abnormal equipment behavior.

A specific advantage of this generic monitoring technique

is that it can be applied to a variety of instrumented

equipment. Many ­out-of-date calibrations, missing or

­incomplete tag suites, and bad sensors can be accommodated with the modeling tool.

If any kind of abnormal equipment behavior is ­detected,

the ­system is designed to automatically notify Siemens

­experts to conduct a detailed analysis of the behavior.

By using these analyses as the basis for diagnostics, a

list of recommendations for immediate actions to avoid

operational restrictions can be generated. In the event

a shutdown is required to remedy the situation, a planned

outage can be used to implement corrective measures.

Several customers have already taken advantage of these

options supported by Siemens expertise.

Based on the operational data, Siemens can provide

­regular availability and reliability reports for the customer

according to IEEE standard. Using the Siemens Operating

Feedback Log (SOFL), the reports could be automatically

created, reviewed by Siemens experts, and sent to the

customer for release. By providing regular feedback of

the operational behavior, customers are able to compare

their own units with the Siemens fleet.

Technical experts using several diagnostic modules help identify, assess, and diagnose abnormal

operating conditions and recommend follow-up actions.

We help you optimize your maintenance

­resources.

9

Further developments

Today, Siemens Power Diagnostics Service consists

mainly of monitoring and diagnostics. However,

with the further d

­ evelopment of our tools and

modules, even remote services for power plant

equipment may become reality in the future.

Some of these new services have already been

­established, such as Remote Balancing, Remote

Tuning, and Remote Field Assistance (RFA).

»

»

»

I simply want to let everyone

know that the team at Power

­Diagnostics Service has provided

excellent s­ upport to our staff.

«

It is a good product. It makes you

aware of problems that otherwise

are very hard to spot. It has saved

us from shutdowns in the past.

We congratulate ­Siemens on this

product.

«

It’s nice to have a team of

smart guys on hand that ­integrate

well with our resources.

7

«

Published by and copyright © 2011:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, please contact

our Customer Support Center.

Phone:+49 180 524 70 00

Fax: +49 180 524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

Energy Service Division

Order No. E50001-G520-A343-V1-4A00 | Printed in Germany |

Dispo 34805 | c4bs No. 7816, 7821, 7822, 7823 |

TH 258-110226 | BR | 460003 | WS | 09111.0

Printed on elementary chlorine-free bleached paper.

All rights reserved.

Trademarks mentioned in this document are the property

of Siemens AG, its affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document contains general descriptions

of the technical options available, which may not apply in all cases.

The required technical options should therefore be specified in

the contract.