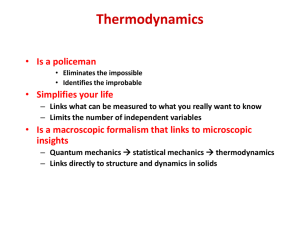

Fundamental Concepts of Thermodynamics

advertisement

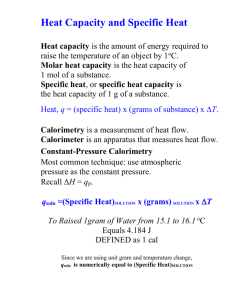

Fundamental Concepts of Thermodynamics • • • • First, second, and third law Entropy Heat capacity, enthalpy Reaction enthalpies and thermochemical cycles • Phase transitions • Calorimetry Why I Count Calories for a Living • They are fascinating – Energetics whisper secrets of the strength of chemical bonds – Entropies sing of vibrating atoms, moving electrons, and structural disorder – Systematics have predictive power • They pay – thermodynamic data are essential to good materials processing – Environmental science needs thermodynamics, both for issues of stability and as a starting point for kinetics – Mineralogy, petrology, and deep Earth geophysics need thermodynamic data. Calorimetry Measures • Heat capacities • Heats of phase transitions’ • Heats of formation From these data one calculates • Entropies and free energies • Solubililities • Phase diagrams • Petrologic and geochemical processes • Materials synthesis and compatibility Phase Transitions Low temperature heat capacity and standard entropy, Fe2SiO4 olivine and spinel, calorimetry on a chip Thermal Analysis and Scanning Calorimetry • Measure a signal (mass, heat, evolved gas, lemgth, X-ray pattern) at a variable heating (cooing) rate • Systems – Room temp to 600 oC, common – 600-1500 oC, less common but we have – 1500-2400 oC, uncommon but we have Example: HfO2 Unit cell volume, Å 3 Mon (P21/c) 144 Cub (Fm3m) Tetr (P42/nmc) ZrO2 HfO2 140 J. Wang et al. J. Mat. Sci. 92, 27(20) 5397 400 800 1200 1600 2000 Temperature, °C Experiment: HfO2_calibr_probe_3rd_heating Displacement/µm SETSYS Evolution - 2400 Probe: Graphite Carrier gas: Length (mm): 2.502 mm Procedure: 1500>2300 (Zone 1) 0.0 TMA on HfO2 Heating -5.0 -10.0 Delta : -0.71 % Delta : 1.01 % -15.0 -20.0 Cooling -25.0 1800 1850 1900 Furnace temperature /°C TMA traces of HfO2 (1.5 % Zr) in Ar flow. (HfO2 pellet L 2.5 mm Ø 5 mm sintered at 1700 °C for 2 hours). Heating rate 10 °C/min. 5 gram load. \ SETSYS Evolution - 2400 Experiment: 3rd_HfO2_W_10_1950 Crucible:W 85 µl Carrier gas: Procedure: 20>2000 (Zone 3) Molar mass: 210.49 Mass (mg): 205.71 DTA signal, µV -bl_cooling - 4 - 3r d_HfO2_W_10_1950/µV -bl 2/µV Exo 2 2.5 Exo 1 1.5 Peak :1762.13 °C Onset Point :1771.45 °C Enthalpy /µV.s : -126.0198 (Exothermic effect) Cooling 0 -1 0.5 Heating -0.5 Peak :1813.08 °C Onset Point :1802.64 °C Enthalpy /µV.s : 127.6076 (Endothermic effect) 1700 1750 1800 Sample temperature/°C DTA traces of HfO2 (99.95% Aldrich) in Ar flow. Heating rate 10 °/min, cooling rate 20 °/min. Baseline correction applied. High Temperature Oxide Melt Solution Calorimetry • Dissolve oxide samples (5-15 mg) in a molten oxide solvent (20 g) at to form a dilute solution • Difference in heat of solution of reactants and products gives heat of reaction • Oxidative reactions for nitrides, sulfides, selenides, carbides • Needed for ceramic materials which do not dissolve in aqueous solvents Solvents and Systems • Lead borate (2PbO-4B2O3, sodium molybdate (3Na2O-4MoO3), alkali borate • Oxides dissolve • H2O and CO2 evolve as gases • Nitride oxidized to evolved N2 • Sulfide oxidized to dissolved sulfate High-Temperature Calorimetry TTD SOL DS 25oC 25oC 25oC HSOL HTTD 700oC HTTD 700 C 25C HDS 700oC CP dT 700oC HDS HTTD HSOL Thermochemical Cycles Perovskites • 1. AO(xl, 298K) = AO(dissolved, 973K) • 2. BO2(xl, 298K) =BO2(dissolved, 973K) • 3. ABO3(xl, 298K) = ABO3(dissolved, 973K) ______________________________ • 4. AO(xl, 298K) + BO2(xl, 298K) = ABO3(xl, 298K) , H4 = H1 + H2 – H3 • Tolerance factor t = dAO/1.414dBO Gas Adsorption Calorimetry • Combine sensitive microcalorimeter with automated gas dosing system • Measure heat of adsorption and adsorption isotherm simultaneously • Apply to high surface area and microporous materials Volumetric dosing system Calvet-type twin microcalorimeter Micromeritics ASAP2020 Setaram DSC 111 sample thermopiles reference H2O to voltmeter and amplifier Differential (a) and integral (b) heats of H2O adsorption for anatase with surface area of 90, 200 and 240 m2/g and rutile of 61 and 103 m2/g (Levchenko et al. 2006). The Peter A. Rock Thermochemistry Laboratory • A unique suite of equipment and expertise • Can design a calorimetric experiment to suit almost any material and problem