Ch3_f03_305

advertisement

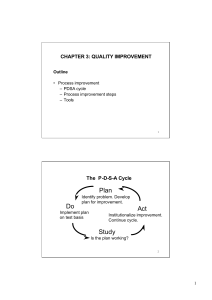

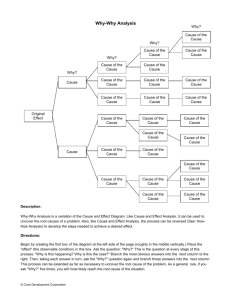

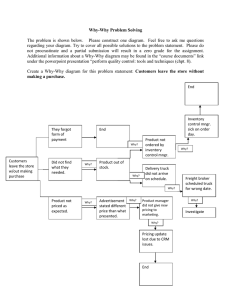

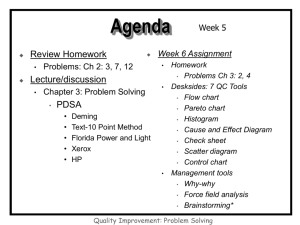

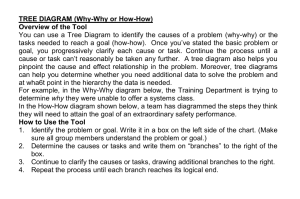

CHAPTER 3: QUALITY IMPROVEMENT Outline • Process improvement – PDSA cycle – Process improvement steps – Tools 1 The P-D-S-A Cycle Plan Do Identify problem. Develop plan for improvement. Implement plan on test basis Act Institutionalize improvement. Continue cycle. Study Is the plan working? 2 Steps in Process Improvement • Plan 1: Recognize problem 2: Form quality improvement teams 3: Define problem 4: Develop performance measures 5: Analyze problem 6: Determine possible causes 3 Steps in Process Improvement • Do 7: Implement solution • Study 8: Evaluate solution • Act 9: Ensure performance 10: Continuous improvement 4 Plan: Steps 1 and 2 1: Recognize problem – Existence of the problem is outlined – In general terms, specifics are not clearly defined – Solvability and availability of resources are determined 2: Form quality improvement teams – Interdisciplinary – Specified time frame – Quality circle 5 Plan: Step 3 3: Define the problem – Define the problem and its scope – Pareto analysis – Brainstorming – Why-why diagram 6 Number of defects 50 100 40 80 30 60 20 40 10 20 0 0 Cumulative percentage Pareto Chart 7 Pareto Chart 40 100 80 C 30 60 20 40 10 20 D A 0 Cumulative percentage Number of defects 50 B 0 Defect type 8 Pareto Chart 40 100 80 C 30 60 20 40 10 20 D A 0 Cumulative percentage Number of defects 50 B 0 Defect type 9 70 Pareto Chart (64) Percent from each cause 60 50 40 30 20 (13) 10 (10) (6) (3) 0 Causes of poor quality (2) (2) Why-Why Diagram • A technique to understand the problem • Does not locate a solution • The process leads to many reasons the original problem occurred • Example: A mail-order company has a goal or reducing the amount of time a customer has to wait in order to place an order. Create a why-why diagram about waiting on the telephone. 11 Why-Why Diagram Waiting on the Why? phone to place an order Why? Why? Insufficient operators available Many customers calling at the same time Why? Why? Workers not scheduled at peak times Low pay All catalogs shipped at the same time 12 Plan: Step 4 4: Develop performance measures – Set some measurable goals which will indicate solution of the problem – Some financial measures: costs, return on investment, value added, asset utilization – Some customer-oriented measures: response times, delivery times, product or service functionality, price – Some organization-oriented measures: employee retention, productivity, information system capabilities 13 Plan: Steps 5 and 6 5: Analyze problem – List all the steps involved in the existing process and identify potential constraints and opportunities of improvement – Flowchart 6: Determine possible causes – Determines potential causes of the problem – Cause and effect diagrams, check sheets, histograms, scatter diagrams, control charts, run charts 14 Flowchart Operation Delay Storage Transportation Inspection Decision Enter emergency room Flowchart Fill out patient history Walk to triage room Nurse inspects injury Return to Wait waiting for ER bed room Walk to ER bed Walk to Radiology Doctor inspects injury Wait for doctor Walk to radiology Flowchart Technician Return to Wait for X-rays ER bed doctor to patient return Doctor provides diagnosis Return to Waiting Leave Building Pickup prescription Walk to pharmacy Checkout Cause and Effect Diagram • Common categories of problems in manufacturing – 5 M’s and an E • Machines, methods, materials, men/women, measurement and environment • Common categories of problems in service – 3 P’s and an E • Procedures, policies, people and equipment 18 Cause and Effect Diagram Measurement Faulty testing equipment Incorrect specifications Improper methods Inaccurate temperature control Dust and Dirt Environment Men/Women Machines Out of adjustment Poor supervision Lack of concentration Tooling problems Inadequate training Old / worn Quality Problem Defective from vendor Not to specifications Materialhandling problems Materials Poor process design Ineffective quality management Deficiencies in product design Methods 19 Check Sheet COMPONENTS REPLACED BY LAB TIME PERIOD: 22 Feb to 27 Feb 1998 REPAIR TECHNICIAN: Bob TV SET MODEL 1013 Integrated Circuits Capacitors Resistors Transformers Commands CRT |||| |||| |||| |||| |||| |||| || || |||| | Frequency of calls Histogram 40 35 30 25 20 15 10 5 0 1 2 6 13 10 16 19 17 12 16 20 17 13 5 6 2 Telephone call duration, min 1 Number of tears Scatter Diagram . Rotor speed, rpm Control Chart 27 Number of defects 24 UCL = 23.35 21 c = 12.67 18 15 12 9 6 LCL = 1.99 3 2 4 6 8 10 12 Sample number 14 16 Do: Step 7 7: Implement the solution – The solution should • prevent a recurrence of the problem • address the root cause of the problem • be cost effective • be implemented within a reasonable amount of time – Force-field analysis 24 Do: Step 7 – Force-field analysis • A chart that lists – the positive or driving forces that encourages improvement as well as – the restraining forces that hinders improvement – Actions necessary for improvement 25 Do: Step 7 Example: create a force-field diagram for the following problem: – Bicycles are being stolen at a local campus. Campus security is considering changes in the bike rack design, bike parking restrictions and bike registration to try to reduce thefts. Thieves have been using hacksaws and bolt cutters to remove locks from the bikes 26 Reading • Chapter 3: – Reading pp. 64-97 (2nd ed.), pp. 52-102 (3rd ed.) 27