ASQ Process Capability Overview Mar 10

advertisement

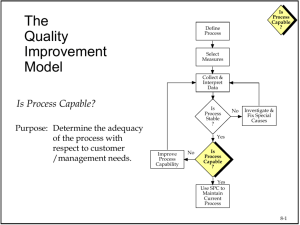

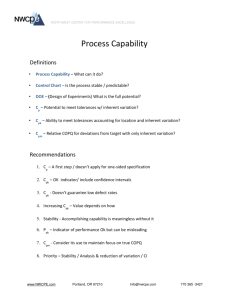

Process Capability ASQ Section 1404 Ken Fredryk March 10, 2015 Process Capability We continually gather data on our process but can we emphatically answer this question: “How well can the process produce products to meet costumer specifications?” Gathering and analyzing data to answer that question is called a Capability Study Process Capability Definition The degree to which a process is able to meet defined tolerance limits (aka specification limits) A measurable property of a process related to customer specifications and process output • Based on statistical evaluation of a process to measure inherent variability compared to the specification/tolerance limits Process Capability Components Two factors of process capability 1. Measurement of inherent process characteristics ‒ Location of the mean ‒ Variation in terms of standard deviation 2. Specification Limits Expressed as a process capability performance index • CP or CPK • PP or PPK Process Capability – Another View Quantifiable comparison of Voice of Customer (spec limits) to Voice of the Process (control limits) Most process measures have some target value and acceptable limits of variation around the target The extent to which the “expected” values fall within tolerance limits determines how capable the process is of meeting its requirements Process Capability Consider key measures of process performance in: • Help Desk Responsiveness • Customer Queue Time • Service Cost / Order • Revenue / Employee • Proposal Acceptance Rate • Service Complaints • On-Time Delivery • Days On-Hand Inventory Why Conduct a Capability Study? Process capability is a tool evaluate how well a process can produce products or services that meet customer specifications May be required to a secure a contract Validate new equipment Provides direction about how to improve process performance Uses of Capability Analysis Performed on existing processes as a means of establishing a baseline of current operations Provide verification that processes meet contractual requirements When done periodically is a means of monitoring deterioration of a process (system, equipment, environment, etc.) Rationale of a Capability Study Optimize process performance by minimizing variation and centering around the target Process target from this Process target to this m m Non-Capable Process Capable Process Not a silver bullet!! Causes of Low Process Capability Excess variation resulting from: • Process design ‒ Poor design, lacking SOP, people, equipment, training, measurement, material ‒ Remember the 6 M’s • Unreasonably tight specifications • Process not centered Process Capability Requirements Type of data determines how to conduct the study • Attribute/discrete data • Continuous/variable data Process must be stable and in control Need to identify distribution characteristics of data • CP and CPK are sensitive to data normality Reliable measurement system • Measurement system must be verified prior to conducting a Capability Study ‒ aka MSA Process Capability – 30,000 ft. View What Type of Data Do You Have? Attribute Data Variables Data Collect Data on Process Collect Data on Process Analyze Data in Excel Analyze Data in Minitab/Excel State Capability DPU, Sigma Quality Level, PPM State Capability DPU, Sigma, PPM, Cp, Cpk, Pp, Ppk Process Stability Is Crucial Stability is needed for process capability • Process output will be predictable • Nearly all outcomes (99.7%) will lie within ±3s of the process mean for Normal Data • Capability ratios will be meaningful When there is no stability, there is NO capability • Process output will not be predictable • The rule of ±3s does not apply • Capability ratios will be meaningless A Stable Process May Not Be Capable The process has too much variation • Without decreasing process variation, some out of specification product is inevitable The process is not centered The specification limits are too close together • The process does not have enough room to move. Without a decrease in process variation or a widening of the specifications, some out of specification product is inevitable Voice of the Process Voice of the Customer Process Capability Ratios “Merge the Voices” Normal Distribution The area under sections of the curve can be used to estimate the cumulative probability of a certain event occurring m Process Capability: The Two Voices 99.73% of values -3s +3s Natural Process Variation m LSL USL Process Capability Voice of the Process Always estimated by (±) 3 standard deviations from the mean (the “Natural Process Limits”) Therefore, six standard deviations in total Visualizing Process Capability Examples of Capable Processes LSL USL LSL USL m 3s m 3s Process is barely capable as long as it remains centered within the specification limits 3s 3s Process is capable and will remain so, even if the process average is moved. Often called process shift Examples of Non-Capable Processes LSL USL m 3s 3s Product produced beyond both upper and lower spec limits. LSL USL 3s m 3s Product produced above the upper spec limit. LSL 3s USL m 3s Product produced below the lower spec limit. Capability Study Options Process Data for Co2 15 UCL=14.18 IndividualValue 14 13 X=12.64 12 LCL=11.10 11 10 9 0 50 100 150 Observation Number Process Data for Co2 15 UCL=14.18 IndividualValue 14 13 X=12.64 12 LCL=11.10 11 10 9 0 50 100 Observation Number 150 A short-term capability study covers a relative short period of time during which extraneous sources of variation have been excluded. (Guideline: 30-50 data points.) A long-term capability study covers a longer period of time in which there is more chance for a process shift. (Guideline: 100200 data points.) Steps of a Capability Study 1. Set the process to run as it normally would and record the values of the input variables 2. Execute the process over a period of time suitable 3. to the purpose of the study • Have all sources of variation been accounted for? 3. Take plenty of notes 4. Measure and record values of the output Steps of a Capability Study (continued) 5. Conduct Analysis (e.g. Minitab, Excel) to study: • Stability • Normal Plot • Histogram • Capability Ratios 6. Develop an action plan based on diagnostics. Sigma Level - s Definition: The number of total standard deviations (+/–) that would fit within the spec limits • For example, a 3s level would mean 6 standard deviations can fit within the specification limits Sigma Level is a measure of the process performance Compare % Defective With and Without Shift Calculated using a “shift” factor Calculated as the area under the curve Process Capability versus PPM Defects s level: • A 6s level is 6 standard deviations or sigmas from the mean • This would be 12 standard deviations, or 12s! • PPM: number of defects per million opportunities Compare PPM Defects With and Without Shift Graphical View of Sigma Levels LSL USL LSL USL +1 s +4 s +2 s +5 s +3 s m +6 s m Process Capability – Cp Ratio of total variation allowed by the specification to the total variation actually measured from the process Typical targets for Cp are greater than 1.33 (or 1.67 for safety items) If Cp < 1, then the variability of the process is greater than the specification limits Cp takes into account only process spread and not location Process Capability – Cp Cp = Allowable variation (spec width) OR Cp = USL – LSL 6s Process Variation • Typical values: – Marginal Cp = 1.00 – Acceptable Cp=1.33 – Good Cp = 1.67 – Six Sigma level Cp = 2.00 One-Sided Capability Ratios If a process has just one spec (either USL or LSL), a one-sided capability ratio (CPU or CPL) is calculated • It takes into account process spread and location CPU = USL – Xbar 3s CPL = Xbar - LSL 3s Typical Values (when the “shift” is taken into consideration) – Marginal CPU or CPL = 1 – Good CPU or CPL = 1.33 – Six Sigma CPU or CPL = 1.5 Centered Capability Ratio, CPK If the spec is two-sided, the centered capability ratio can be calculated • It is the smaller of CPU and CPL CPK = Minimum (CPU or CPL) Relationship Between CP and CPK CPK = CP (1-K) • K 0 is a “shift factor” • CPK is always less than, or equal to CP • Typical values (when the “shift” is taken into consideration): – Marginal CPK = 1 – Acceptable CPK = 1.33 – Six Sigma CPK = 1.5 m Negative Cpk LSL USL • Negative Cpk occurs when the mean is outside the USL or LSL e.g. Cpk = -0.5 3s 3s Process mean is outside the specification limit Capability versus Performance • Capability Ratios (CP and CPK) – use a short-term estimate of sigma (s) obtained from the withinsubgroup variation – show what the process would be capable of if it did not have shifts and drifts between subgroups • Performance Ratios (PP and PPK) – use a long-term estimate of sigma (s) obtained from within-subgroup plus between-subgroup variation – Show what the overall variation is • Performance ratios will be worse (smaller) than the corresponding capability ratios if the process has shifts and drifts The Dynamic Process LSL USL Process Capability Process Performance Over time, a process tends to shift by approximately 1.5 s Capability Example Sample data of pin diameters • Data collected over 27 days • Sub-group size 5 • Tolerance is 0.1587 – 0.20885 P G A Approach (aka KFred rule of thumb: Always do PGA) Capability Example Data Sample1 Sample2 Sample3 Sample4 Sample5 Subroup 1 0.175 0.174 0.179 0.189 0.184 2 0.194 0.192 0.189 0.189 0.18 3 0.199 0.197 0.195 0.172 0.182 4 0.184 0.18 0.179 0.185 0.189 5 0.177 0.175 0.192 0.187 0.187 6 0.179 0.177 0.189 0.19 0.177 7 0.18 0.187 0.179 0.195 0.187 8 0.18 0.179 0.192 0.179 0.189 9 0.184 0.184 0.195 0.187 0.185 10 0.17 0.184 0.174 0.179 0.187 Control Chart by Subgroup Capability Analysis 1 Normality Test Capability Analysis by Subgroup Capability Analysis 1 Capability Analysis 1 Capability Analysis 2 Capability Analysis 2 Excel Based X Bar R Chart Limits UCL X 0.189891 LCL X 0.177709 UCL R 0.022325 X Median Chart Limits UCL X 0.193343 LCL X 0.178776 UCL R 0.022325 Pre-Control Limits Upper PC line 0.196325 Lower PC line 0.171275 # of Samples # of Sub Groups Sub Group Size (n) Max Value Min Value Range X Double Bar R Bar St. Dev. (Rbar/d2 ) St. Dev. (Indiv.) Normality Process Data 135 USL 27 LSL 5 UCL X 0.197 LCL X 0.175 UCL R 0.022 Z USL 0.186059 Z LSL 0.01 % Above USL= 0.004538 % Below LSL= 0.004845 % In Spec= Normal % Out of Spec= Cap_Study_.xls.xlsx 0.20885 0.15875 0.1921498 0.1799687 0.022325 4.7039663 -5.63658 0.0% 0.0% 100.0% 0.0% Potential (Rbar/d2 ) Capability Cp 1.84 CpU 1.67 CpL 2.01 Cpk 1.67 Cr 0.54 Potential (Indiv.) Capability Pp 1.72 PpU 1.57 PpL 1.88 Ppk 1.57 Pr 0.58 Capability Analysis Comparison Original Data (Non-Normal) Minitab Potential (Within) Capability Cp 1.77 CPL 1.94 CPU 1.61 Cpk 1.61 Overall Capability Pp 1.72 PPL 1.88 PPU 1.56 Ppk 1.56 Transformed Data Minitab Potential (Within) Capability Cp 1.77 CPL 1.48 CPU 2.06 Cpk 1.48 Overall Capability Pp 1.71 PPL 1.43 PPU 2.00 Ppk 1.43 Original Data (Non-Normal) Excel Potential (Rbar/d2 ) Capability Cp 1.84 CpU 1.67 CpL 2.01 Cpk 1.67 Cr 0.54 Potential (Indiv.) Capability Pp 1.72 PpU 1.57 PpL 1.88 Ppk 1.57 Capability Analysis Comparison Original Data Subgroup Size 5 Potential (Within) Capability Cp 1.77 CPL 1.94 CPU 1.61 Cpk 1.61 Overall Capability Pp 1.72 PPL 1.88 PPU 1.56 Ppk 1.56 Original Data Subgroup Size 1 Potential (Within) Capability Cp 1.92 CPL 2.09 CPU 1.75 Cpk 1.75 Overall Capability Pp 1.72 PPL 1.88 PPU 1.57 Ppk 1.57 Results Is the process stable? YES Are the data normally distributed? No What is the standard deviation (within) of the process? Approximately 0.0047 What are CP and CPK? 1.77 and 1.61, respectively What are the PPM (use the “within” performance)? Approximately 1 But what if we have only attribute data? Attribute & Continuous Data Comparison Attribute Continuous Process Capability from Count Data Process capability for count data is assessed differently from continuous data Summary of process capability using count data • Control Chart (I-MR) • DPU, DPMO and Sigma Level metrics • Ability to meet customer requirement Process must be stable; otherwise, there is no capability Attribute Capability Example • Customer spec is sigma quality level > 3.5 • Last month 16,810 units were produced over 18 days • 231 were defective • Did we meet customer requirements? Attribute Capability Analysis • Does the control chart show a stable process? • What are DPU? • What are DPMO? • What is the sigma level? • Does the process meet customer requirements? Attribute Capability Analysis Date 8/1/1998 8/2/1998 8/3/1998 8/4/1998 8/5/1998 8/6/1998 8/7/1998 8/8/1998 8/9/1998 8/10/1998 8/11/1998 8/12/1998 8/13/1998 8/14/1998 8/15/1998 8/16/1998 8/17/1998 8/18/1998 No. Leaks 28 7 11 27 11 5 8 21 16 21 7 23 1 5 11 15 10 4 No. Brakes 770 890 930 960 800 1170 1010 990 990 1010 630 1010 650 1000 1000 990 1000 1010 Avg. Defect Rate I and Chart MR Chart for RateRate I and MR for 0.04 3.0SL=0.03989 0.03 0.02 X=0.01382 0.01 0.00 -0.01 -3.0SL=-0.01224 -0.02 Subgroup 0 10 20 3.0SL=0.03202 0.03 0.02 0.01 R=0.009801 0.00 -3.0SL=0.00E+00 Is the process stable? What Are the Defects per Unit (DPU)? Formula: DPU = Total # Defects Total Units Produced Example: DPU = 231 = 0.0137418 16810 What Are the Defects per Million Opportunities (DPMO)? Formula: DPMO = DPU X 1,000,000 Total Opportunities for a Defect in One Unit Example: DPMO = 231 (1M) = 13,741.8 16810 What Is the Process Sigma Level? Procedure: Use the Excel file sigmacalc.xls ATTRIBUTE SIGMA CALCULATOR Characteristic Under Study: # of Units Opportunity For Defects / Unit Defects DPU DPMO SIGMA (With Shift) Brakes 16810 1 231 0.01374182 13741.82035 3.71 Another Example Attribute Capability Study Process: Bank Loan Application Review Objective: Determine the capability of completed loan applications Inspect completed loan applications for defects • What is a defect? ‒ Need operational definition of a defect • Validate measurement system – Conduct attribute MSA • Tally defects • Calculate sigma level Another Example Attribute Capability Study Process: Bank Loan Application Review 500 random applications reviewed 5 fields per form are required to be completed by the applicant Operational definition of a defect • Missing, illegible or wrong format fields 260 defects identified Capability Summary Capability ratios are used to compare the VOC (specs) to the VOP (natural process limits) For a capability ratio to be a good predictor of future performance, the process must be stable The two key ways to improve process capability are to reduce variation and to improve centering A capability ratio should never be interpreted without a histogram of the process to ensure normality Because these indices are unit-less, you can use capability statistics to compare the capability of one process to another References Dean Cristolear • Cap_Study.xls iSixSigma.org 6Sigma.org ASQ.org • Six Sigma Forum Magazine May 2005: –Capability Indexes: Mystery Solved