Quality Control Exercises

advertisement

Quality Control Exercises

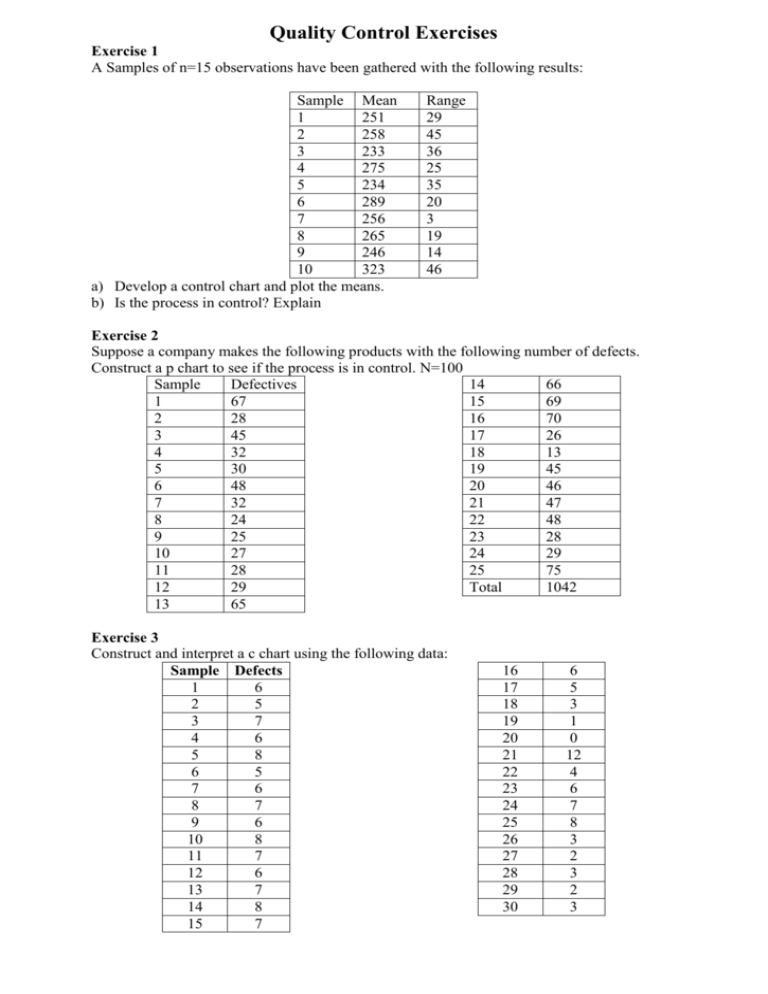

Exercise 1

A Samples of n=15 observations have been gathered with the following results:

Sample Mean

1

251

2

258

3

233

4

275

5

234

6

289

7

256

8

265

9

246

10

323

a) Develop a control chart and plot the means.

b) Is the process in control? Explain

Range

29

45

36

25

35

20

3

19

14

46

Exercise 2

Suppose a company makes the following products with the following number of defects.

Construct a p chart to see if the process is in control. N=100

Sample

Defectives

14

66

1

67

15

69

2

28

16

70

3

45

17

26

4

32

18

13

5

30

19

45

6

48

20

46

7

32

21

47

8

24

22

48

9

25

23

28

10

27

24

29

11

28

25

75

12

29

Total

1042

13

65

Exercise 3

Construct and interpret a c chart using the following data:

Sample Defects

1

6

2

5

3

7

4

6

5

8

6

5

7

6

8

7

9

6

10

8

11

7

12

6

13

7

14

8

15

7

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

6

5

3

1

0

12

4

6

7

8

3

2

3

2

3

Exercise 4

For each of the accompanying control charts , analyze the data using both median and

up/down run test with z=±1,96 limits. Are nonrandom variants present? Assume he center line

is long term median.

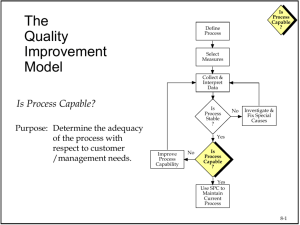

Exercise 5

Tolerances for a new assembly call for weights between 32 and 33 pounds. The assembly is

made using a process that has a mean of 32,6 pounds with a population standard deviation of

0,22 pounds. The process population is normally distributed.

a) Is the process capable?

b) If not, what proportion will not meet tolerances?

Solution

Exercise 1

x1 x 2 .... x m

x

263

m

R R2 ...... R3

R 1

27,2

m

UCLx x A2 R 263 0,223 27,2 269,07

LCLx x A2 R 263 0,223 27,2 256,93

x-bar chart

Mean

300

250

200

1

2

3

4

5

6

7

8

9

10

Sample

UCLR D4 R 1,652 27,2 44,96

LCLR D3 R 0,348 27,2 9,47

Range

range chart

50

40

30

20

10

0

1

2

3

4

5

6

Sample

Exercise 2.

np

1042

p

0,4168

n

25 100

p(1 p)

0,4168 0,5832

p

0,0493

n

100

UCLp p z p 0,4168 3 0,0493 0,5647

LCL p p z p 0,4168 3 0,0493 0,2689

7

8

9

10

p-chart

Mean

0,8

0,6

0,4

0,2

0

1

2

3

4

5

6

7

8

9

10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

Sample

Exercise 3

c

164

5,47

30

UCLc c 3 c 5,47 3 5,47 12,486

LCLc c 3 c 5,47 3 5,47 1,546 0

c-chart

Mean

15

10

5

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

Sample

Exercise 4

Median A/B: AA BB A B A BB A B AA B AAA BBB A B A B A B 18

Up/Down: DDD U D U DD U D UU D UU DDD UU D U D U D 17

N=26

N

26

E (r ) med 1

1 14

2

2

2 N 1 2 26 1

E (r ) u / d

17

3

3

N 1

26 1

med

2,5

4

4

16 N 29

16 26 29

u/d

2,07

90

90

observed exp ected 18 14

z med

1,6

deviation

2,5

observed exp ected 17 17

zu / d

0

deviation

2,07

Both value fall into the interval (-1,96;1,96), thus the process is in control, only random

variant is present.

Exercise 5

USL LSL 33 32

Cp

0,5051

6

6 0,22

(USL ) 33 32,6

0,6061

3ˆ

3 0,22

( LSL) 32,6 32

Cpl

0,9091

3ˆ

3 0,22

Cpk min{ Cpu; Cpl ) 0,6061

the process is not capable, because both Cp and Cpk are under 1.

b)

x 33 32,6

z

1,818

0,22

x 32 32,6

z

2,727

0,22

0,0344+0,0032=0,03763,76% of products doesn’t meet specification

Cpu

Appendix

Sample size, n

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Mean

Factor,

A2

1,88

1,023

0,729

0,577

0,483

0,419

0,373

0,337

0,308

0,285

0,266

0,249

0,235

0,223

0,212

0,203

0,194

0,187

0,18

0,173

0,167

0,162

0,157

0,153

Upper

Range,

D4

3,268

2,574

2,282

2,115

2,004

1,924

1,864

1,816

1,777

1,744

1,716

1,692

1,671

1,652

1,636

1,621

1,608

1,596

1,586

1,575

1,566

1,557

1,548

1,541

Lower

Range,

D3

0

0

0

0

0

0,076

0,136

0,184

0,223

0,256

0,284

0,308

0,329

0,348

0,364

0,379

0,392

0,404

0,414

0,425

0,434

0,443

0,452

0,459