Process Capability

advertisement

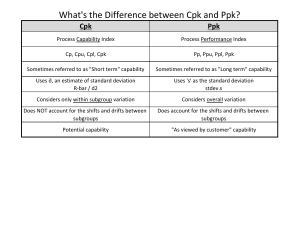

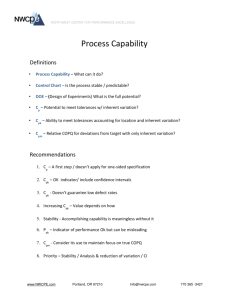

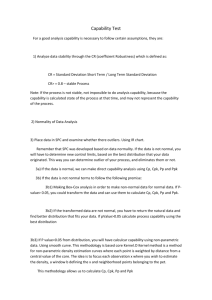

www.stangerweb.de Process Capability Training and Explanation 1 www.stangerweb.de Purpose of EasyTools There are lots of Quality tools around that can help improving many situations of the daily quality life. The problem with many tools is that you need training and experience to use them effectively. EasyTools is a collection of easy to use and mostly self explaining tools that everybody can use. No need for weeks of training or years of experience. 2 www.stangerweb.de Purpose and Contents Purpose: • To get a basic feeling on capability studies. Contents: • Normal Distribution • Scattering • Process Potential • Machine Capability • Process Capability • Preliminary Process Capability • Formulas for capability and potential • Customer and internal requirements 3 www.stangerweb.de The Normal distribution Assume you have a chicken farm and you measure the weight of the eggs. Their weight is around 50g – means some eggs have only 45g but some have 55g. If you make a distribution curve where you show how many eggs have what weight, you will get following curve. 0,0900 m = 50 0,0800 0,0700 0,0600 0,0500 0,0400 0,0300 0,0200 Sigma = 5 0,0100 0,0000 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 4 www.stangerweb.de Capability The Capability is the ratio of Tolerance to Scattering 90 80 70 60 Tolerance Scattering 50 40 30 20 10 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 5 www.stangerweb.de How to measure scattering? Assume you have a normal distribution – then 99% of all data lie within +- 3 sigma. The capability is 1 if ~99% of the data lie within the tolerance (+- 3 sigma). +-Sigma +-2 Sigma +-3 Sigma The capability is better than 1 if more than ~99% of the data lie within the tolerance. 6 www.stangerweb.de Potential versus capability The better the data lie in the middle of the tolerance the better the capability. The potential is what we could achieve if the scattering is the same but the data would lie in the middle. 7 www.stangerweb.de Different capability types Cmk - Machine capability Short term study. Take a sample of e.g. 50 parts as they are produced, measure the characteristic you are interested and calculate the Cmk. Cpk - Process capability Long term study. Take samples over a long time (e.g. 3 month; e.g. each week 5 parts), measure the characteristic you are interested and calculate the Cpk. Ppk – Preliminary Process capability Mid term study. Take samples over a mid time (e.g. 3 weeks; e.g. each day 3 parts), measure the characteristic you are interested and calculate the Ppk. 8 www.stangerweb.de Capability formulas The formulas for Cpk and Ppk are the same as for Cmk. 9 www.stangerweb.de Potential formulas USL - LSL Cm = 6s The formulas for Cp and Pp are the same as for Cm. See visualisation of capability A comprehensive article about capabilities can be found at http://www.itl.nist.gov/div898/handbook/pmc/section1/pmc16.htm 10 www.stangerweb.de Capability requirements Our Customers’ requirements are: Cpk > 1.00 Cpk for safety items > 1.33 Our requirements should be: Cpk > 1.33 Cpk for safety items > 1.67 Sigma Cpk ppm 3 1,00 2700 4 1,33 64 5 1,67 0,5 6 2,00 0,002 11