Study guide for quiz 1

advertisement

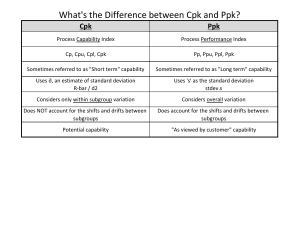

BA 367 Study Guide for Quiz 1 The quiz will be about half multiple choice and half application. You will have about an hour and a half to complete it. Reading The quiz covers weeks 1 and 2 of class, so the corresponding reading from the text applies (chapters 1, 2, 14, and 15 from the 4th Ed. of text), as well as the lecture notes. Topics NOT Covered History of production technology Quality gurus (Deming, Juran, etc.) Deming’s 14 points The DMAIC process in Six Sigma Quality index numbers Zones in control charts Topics Covered Definition of productivity Operations Strategy o Concepts of core competencies, order winners and order qualifiers o Competitive priorities (cost, quality, flexibility, speed) o Product and process strategies (make to order, etc.) o Process strategies (project, batch, etc.) and the changes in production volume and standardization o Service strategies (professional service, etc) o Capacity decisions o Human resource, quality, and sourcing issues in production strategy o Balanced scorecard methods for presenting data; key performance indicators Quality Management o Dimensions of quality (performance, features, reliability, etc.) o Customer focus on quality, versus producer focus on cost o TQM o The PDCA cycle o Quality circles o Six sigma o Quality attributes in service o Costs of quality o For the formulas – know what the terms mean; you don’t have to memorize the formulas The Yield formula - Y=(I)(%G)+(I)(1-%G)(%R) The Product Cost formula; Product Cost = (KdI+KrR)/Y o The seven quality control tools (Ishikawa’s tools) o ISO 9000 Statistical process control o Random versus non-random variability (common and special causes) o Attribute (Y/N) and Variable (numeric) measures o Attribute (p-chart, c-chart) and variable (R-chart and x bar chart) control charts o Mean, upper control limit and lower control limits on control charts o When is a process in control? o For the various control charts – know what the terms in the formulas mean; don’t have to memorize the formulas o Patterns in control charts’ data o Process Capability Ratio; Cp = (upper spec limit – lower spec limit) / (6*sigma) o Process Capability Index; Cpk = min[(x double bar – lower spec limit) / (3*sigma), or (upper spec limit – x double bar) / (3*sigma)] o Good values of Cp and Cpk o What does it mean when Cp and Cpk are very different values Sample application problems might include one or more of: Describe the steps in the PDCA cycle Describe what specific elements mean in the formulas (e.g. what is x double bar, what is I, etc.) Describe and show an example of five of the seven quality control tools For a given measure, describe what kind(s) of control charts would be appropriate, and why Given specific values of Cp and Cpk, describe what that tells you about the process capability and where it is relative to the specification (centered or not) Given a control chart with data, tell if it is a controlled process or not, and why (as in, what rules does it follow or fail) Describe five dimensions of quality for a given product or service Graphically follow the yield formula through production, inspection, and rework processes