BLM_chap_11_slides_

advertisement

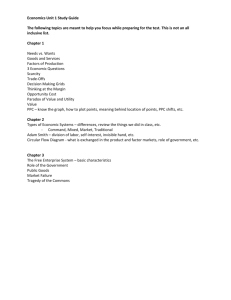

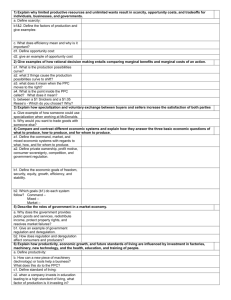

Chapter 11 The design of storage and handling facilities Chapter 11: Strategic Leadership Overview This chapter covers the following topics: • Introduction • Initial requirements • Sizing the warehouse • Operation and warehouse management systems (WMS) • Design process • Fire • Security • Lighting Chapter 11: Strategic Leadership Introduction • Need to understand the principles of the layout of a facility • Allows change that is efficient • Introduces the principles of change or mere expansion • Ongoing changes to a facility requiring adaptation and improvement • The design for a new facility is specialised and beyond this text Chapter 11: Strategic Leadership Design requirements • Should be written and reviewed before any change • Purpose needs to be explicitly defined: - Cross dock - Manufacturing storage warehouse - Distribution centre (and so on) • Growth forecast -Sets the size of any change to cater for the future • Purpose of a facility is defined by a PPC Chapter 11: Strategic Leadership Operations and WMS • Define the methods supported by the warehouse management system (WMS) and what is most efficient for the operation. • Chart the processes. • Identify limitations. • Find solutions that are permitted and suit the operation. Chapter 11: Strategic Leadership Design process • Identify PPCs in the products and processes • For each PPC, record: - Storage requirements - Handling and moving areas - Assembly areas for transport loading and unloading -Receiving requirements Chapter 11: Strategic Leadership PPC combination and optimisation • Define for each PPC: - Which areas are unique to the PPC - Which areas can be combined and the impact on space or congestion -Periods of operation Chapter 11: Strategic Leadership Common areas • If common areas are used in same period, then require increased space above single use, but less than proportion to number of PPCs that will use space. • Example: a travel aisle for two PPCs need only be 50% wider than that required for one PPC use. Chapter 11: Strategic Leadership Aisle sizes between/around racks • Aisle size is determined by equipment used and traffic . • Rack volume to total floor space is important to know, as directly influences quantity of product to be stored – must be able to calculate this. Chapter 11: Strategic Leadership Methods – receiving • Interaction between receipt and put-away determines size of receiving area. • Disciplined placing in lines at all times makes for smaller size. • Partial receipt before put-away begins reduces size necessitated by receiving area. Chapter 11: Strategic Leadership Layout of receiving bay Chapter 11: Strategic Leadership Movement zones Defined to cater for all movement that will occur, reflecting: • Number of PPCs that will use it concurrently (defined by periods of use) • Speed of equipment • Turning and stopping • Flows – one- or two-way increase the size of movement area Chapter 11: Strategic Leadership Other requirements • Pick method • Loading/unloading doors • External truck area Chapter 11: Strategic Leadership Combining areas • Requirements for each PPC • Can use CAD or drawing method • Drawing method: - Record areas on paper layouts (cut out) - Move around on drawing of facility - Unique areas must be allocated so temperatures are graded from lowest to highest and flows are sensibly minimised - Common areas must be combined Chapter 11: Strategic Leadership Other issues • Fire • Safety • Security • Lighting Chapter 11: Strategic Leadership