Continuous Process Improvement: PDSA, PDCA, Juran's Trilogy

Continuous Process Improvement

Achieve Perfection

Work as Process to make it Effective, Efficient, and Adaptable

Changing Customer Needs

Control in process-Reduce Scrap, Time, Idle of Resources

Eliminate Non Conformance in All Phases

Bench Marking

Innovation

Statistical Tools, QFD,FMEA. Taguchi Loss Function

1

Types of Problems

•

Compliance

•

Unstructured

•

Efficiency

•

Process Design

•

Product Design

2

Shewhart’s PDSA CYCLE in 1930

•

PLAN

•

DO

•

STUDY

•

ACT

ACT PLAN

STUDY

DO

3

Continuous Process Improvement

Cycle

Phase 1 Identify the opportunity

Phase 2 Analyze the

Process

Phase 7Plan for the

Future

ACT

PLAN

Phase 3 Develop the

Optimal Solution

Phase 6 Standardize the Solution

STUDY

DO

Phase 5 Study the

Results

Phase 4

Implementation

4

5

The Deming Cycle or PDCA Cycle

PLAN

Plan a change to the process. Predict the effect this change will have and plan how the effects will be measured

ACT

Adopt the change as a permanent modification to the process, or abandon it.

DO

Implement the change on a small scale and measure the effects

CHECK

Study the results to learn what effect the change had, if any.

6

Kaoru Ishikawa has expanded Deming's four steps into six:

Determine goals and targets.

Determine methods of reaching goals.

Engage in education and training.

Implement work.

Check the effects of implementation.

Take appropriate action.

7

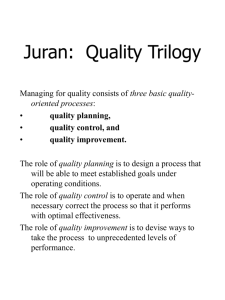

Juran's Trilogy

Juran's Trilogy is possibly the most simple, complete, and pure representation of managing for Quality ever devised. The trilogy exemplifies the essence of

Quality. It completely meets its objective in the most efficient and effective manner possible 8

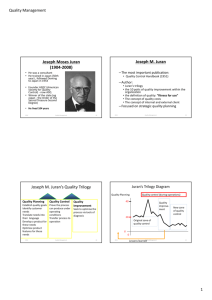

Juran's Trilogy

Quality Planning

Identify the Customers

Determine the customer’ needs

Develop a process

Prove process capability

9

Juran's Trilogy

Quality Control

Choose control Subjects (What to Control)

Choose Units of measurements

Establish Measurement

Establish Standards of performance

Measure actual performance

Interpret the difference

Take action on the difference

10

Juran's Trilogy

Quality Improvement

Prove need for improvement

Identify specific projects for Improvements

Organize to guide & Diagnosis

To find causes

Provide Remedies

Prove remedies for effective in operating conditions

Control the gains

11

JURAN’S QUALITY TRIOLOGY

Cost of

Quality

Quality

Planning

Threshold

Of Plan

Quality

Improvement

Chronic Waste

(An opportunity

For Improvement )

Initial Quality

Zone

Quality

Control

Breakthrough

Quality

Zone

Time

12

Juran’s Spiral of Progress in Quality

Marketing

Operation

Customers

Further Product

Development

Customers

Product

Development

13