Quality Philosophies

advertisement

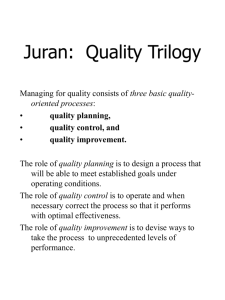

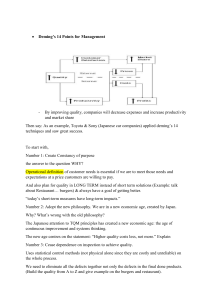

Quality Philosophies 1 Deming 14 Points PDCA Cycle Seven Deadly Diseases Profound Knowledge System View Chain Reaction Statistical Thinking 2 14 Points 1. 2. 3. 4. 5. 6. 7. Constancy of Purpose Adopt New Philosophy Cease Dependence on Mass Inspection Long Term Supplier Relationships Improve Constantly Institute Training Institute Leadership 8. 9. 10. 11. 12. 13. 14. Drive Out Fear Break Down Barriers Eliminate Slogans, Exhortations, and Targets Eliminate Work Standards Remove Barriers Education and Self Improvement Put Everyone to Work on This 3 Seven Deadly Diseases I. II. III. IV. V. VI. VII. Lack of Constancy of Purpose Emphasis on Short Term Profits Evaluation of Performance (Merit Rating) Mobility of Management Management by Use of Visible Figures Excessive Medical Costs Excessive Liability Costs 4 Profound Knowledge Knowledge of Systems Knowledge of Variation Understanding of Psychology or Motivation 5 Deming’s Obstacles Instant Pudding Technology is the Cure Hazard to Copy Quality is Responsibility of Quality Department Zero Defects Only Necessary to Meet Specifications Problems Lie with Workers 6 Deming Chain Improve Quality Costs Decrease Productivity Increases Market Share Increases Stay in Business Provide Jobs 7 Juran Trilogy Pareto Breakthrough Big Q Little q Finance Parallel Self Control 8 Juran’s Quality Trilogy Planning Control Improvement 9 Self Control (Juran) Requires that the individual A. B. C. Know what is required Know how to do it Have a means for regulating performance 10 Juran’s Quality Trilogy Planning Control Improvement 11 Self Control (Juran) Requires that the individual A. B. C. Know what is required Know how to do it Have a means for regulating performance 12 Feigenbaum Total Quality Control – Integrated System – Begins with Customer – Responsibility of General Management 13 Crosby Four Absolutes 1. 2. 3. 4. Conformance to Requirements Prevention Zero Defects Measurement is Cost of Nonconformance 14 Steps of Quality Improvement 14 Crosby’s Absolutes Quality means conformance to requirements Prevention is the system Zero defects is the performance standard Performance measured by cost of non quality 15 Crosby’s 14 Steps Management Commitment Teams Measurement Cost of Quality Awareness Corrective Action Zero Defects Committee Supervisor Training Zero Defects Day Goal Setting Error Cause Removal Recognition Councils Do It all Over Again 16 Covey Seven Habits – – – – – Be Proactive Begin with the End in Mind First Things First Think Win/Win Seek First to Understand, then to be Understood – Continual Self Improvement 17 Walter Shewhart Control Chart Statistical Quality Control Shewhart Cycle 18