College of Business - Iowa State University Extension and Outreach

advertisement

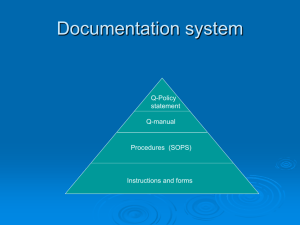

Calculating and Reporting Benefits of QMS Iowa State University of Science and Technology Agriculture and Biosystems Engineering Agriculture and Industrial Technology 7/15/05 Objectives Identify potential benchmark measures of cost/benefit of quality management system adoption by agriculture. Set scope of the project Select summarizing fiscal indicator of costs and benefits measures Dual Roles for ISO 9000/9004 QMS for fulfilling customer, regulatory, etc., requirements (ISO 9000) “Management should consider development of innovative financial methods to support and encourage improvement of the organizational performance” (ISO 9004 – Guidelines for performance improvements) Allocation of Costs: Process Approach Early methods of tracking quality costs was too limited “focus on cost of nonconformance i.e. external and internal failure costs”. Process-cost broadens economics of quality by classifying cost of nonconformance and cost of conformance I.e. “costs incurred when a process is running without failure” (Juran) (Schottmiller) Process Approach: Added Benefits Utilize cost of non-conformance (often called Cost of Poor Quality) and cost of conformance = greater cost saving opportunities may be available in reducing cost of conformance (Schottmiller) Process Costing Allows the tracking and reduction of costs normally associated with efficiency in addition to effectiveness (quality)” Process simplification in addition to reduction of errors become objectives (Schottmiller) (Schottmiller) Relate the economics of quality to the amount of activity performed (ISO/TR 10014: Economics of Quality) Process Costs i.e. Costs of Inefficient Processes Examples Variation of product characteristics from optimum Unplanned downtime and/or loss of processing/storage capacity Inventory shrinkage Variation of process characteristics from ‘best practices’ (cycle times from to start to finish of activities) Other non-value added activities NOTE: Improvement is also an objective Don’t Ignore Quality Failures Cost of Poor Quality Cost of nonconformity: Internal failure costs External failure costs Cost of conformity: process approach Cost of lost opportunities for sales revenue (Juran) Internal Failure Costs Examples Labor and material overhead spent on defective product – spoilage, defectives, scrap etc. Correcting defectives in physical or service products i.e. reworking product Sorting bad/good product Reinspection, retest of product Changing processes to correct deficiencies (CAR’s) Downgrading product (Juran) External Failure Cost Examples Costs involved in replacing/making repair for warranty product Investigation and adjustment costs to justified complaints of quality defective product Returned material Concession costs due to substandard product accepted by customer Correcting errors on external supporting processes Revenue losses in support operations (Gyrna) Allocation of Costs The company must decide what to measure depending upon circumstances, objectives, etc. However, The overall idea is to “allocate costs and not to absorb such costs into overhead” (ISO/TR 10014) Deriving Benefits Reduction of failures due to QMS Improvement of process efficiencies due to QMS – Pre and post measures of implementation However, improvements should be done as identified – Using quality tools such as flowcharting, value add analysis, cycle time reduction, process simplification, root cause investigation, etc. Quality Improvement Examples J OB SET UP Binde r P r ogra m Tooling Tool layout for next jobs Tooling Ope ra tor G et bi nder f or next job Check f or program on m achine P ro gram avai lable ? Mis sing Tooling S etup t ools for next j ob (based on tool layout) P ut tools on cart Y O perat or does tool layout Load pro gram Machine uploads to ol data from program Tool in chain? (machine data) Y N N Check tool cart Tool on cart? N Physically check tool chain Y Tool in chain? (visual) N Y Tool in crib? Y Vi sual inspecti on of t ool OK t o use? N N Y Tool available i n cri b? P ro gra m A djus tm e nts Fix tur ing Change sheets collect ed (Jay/Dave); program retreived f rom f loor Hardrive updat ed f rom f loor prog. Adjust p rogram to m atch new tool; fill program change sheet & hi st ory form Y P ut tool in chain& get fixture, jaws, et c. N P ar t Se tup Mi ssi ng fixture, etc? Y S etup part in machine N Ope r ator / S upe rv isor Look for m issi ng fi xture, ja ws, etc. Y Ga gin g Gagi ng available ? Get gaging for part from t ooling Y 1s t Piec e Run/ Qua lity C he c k B inde r Adjus tme nts Run f irst pie ce on m achine P ut binder at slot by Engr. of fice Y N Fi nd missing part(s)? Look f or gaging Y Y N Ope r ator / Supe r vis or/ T ooling Get program f rom ha rdrive Fi nd program ? N Rewrite prog ram Look for t ool in ot he r m achines Find tool? N S ubst i tute tool? N N N S che dular / S upe rv isor F ind missing gage(s)? Y Wait ? Y Expedit e mi ssing tool, fi xture, or gage Pur c has ing Update binder from histo r sheet ; f ile binder Engine er ing F irst piece check Ce r tifie d 1s t Pie ce C hec k er Flow charting w/ value, non-value add analysis – Green – customer value added activity – Yellow – ‘necessary evil’ – Red – non customer value added Cycle Time Reduction Department:____________________ Part Name:________________________ Date of Timestudy:_______________________ Supervisor:_____________________ Part #:____________________________ Measurer:______________________________ Operator:_______________________Operation:_________________________ Operator Tools:_________________________ Stop watch time study common Also work sampling Better way to get data w/o estimating? Step Element Description 1 2 3 4 5 6 7 8 9 10 TOTAL # Avg Normal Minutes: Foreign Elements: A B Performance Rating Data EP VP Poor Fair Avg Gd VG Exc Sup SKILL: -20 -15 -10 -5 0 5 10 15 20 EFFORT: -20 -15 -10 -5 0 5 10 15 20 10% PF&D: Standard Minutes: Hrs/Piece: Pcs./hour: C D Operator Average at Time of Study: Machine Cycle: Comments: S/E Mins Value Add Analysis Definitions – Value added activity: • only if the customer recognizes its value, • it’s done right the first time, • It changes the product toward something the customer expects – ‘Necessary Evil’ (operational value added activity): • not customer value added but required through law, regulation, or contract • required to support value added activities • technological barrier exists from eliminating activity – Non value added activity: • not valued by customer, • doesn’t change product towards customer value • not required by law, contract Pareto Analysis (80/20 rule) Baseline Data 9/2/03-9/9/03 100 1500 1000 60 40 500 20 0 Defect Count Percent Cum % R R DE N L IS O E W O K V C O F C M L G R N K D G G G ING UN RA CHE ERIA TUP P E ers RIN NA OR HIN ININ LIN G G U E U E S h O W R I T T U T S O A S Ot INT TO N RE GA T PT FIN TR P R PA R MA ER/ F IX A O M D 1S AIT BIN W 403 329 168 162 121 120 72 55 39 38 26 23 23 26 25 20 10 10 8 7 4 3 2 2 2 1 1 2 25 46 56 66 74 81 86 89 92 94 96 97 98 100 0 Percent Count 80 Root Cause Analysis Why-because diagram: ask ‘why’ at least 5 times to reach root cause Lost time to tooling @ workcenter Why-Because Chart - 9/25/03 KRPM Tooling-Red Team Don't know what is in tool chain Tooling not returned to crib after job No tooling inventory updates Load procedure not consistant No spare tooling No trigger to replenish tooling Fixture loading problem Not paying attention No tooling available Tool wear Tooling breaks, machine crashes Operator error Going too fast Takes time to change inserts Take up to tool room to measure Running tool past tool life Fixture quality; design No standardized tooling Not enough tools Most correct measurements Want to hit higher efficiency Programs change Engr. not aware of std. tools $$$ Can't measure all char. @ mach. (binder descp.) (program descp.) Effect Anyone can change programs Same tool but diff. descriptions Tools disappearing from chain Tools used on other jobs Try to change program to match print Same tool but diff. lengths Too much specialized tooling No compatible tool lists btwn. Prod. And Engr. Lengths changed Lack of control over tools descriptions WPC's changed Tool setup diff. from tool room Cause Manufacturer specs. vary Out of tolerance Easy fix 1 pre-setter Improvements Summary Point is to have active system of improvement per ISO guidelines and would bring more value to project and study as a whole Question is: will it confound the measuring of the ISO impact study? Potential Benchmark Measures “The organization can use a variety of financial decision methods (e.g. net present value, payback time, internal rate of return) to decide whether to proceed or not with a cost benefit analysis” (ISO/TR 10014:1998(E): Guidelines for Managing the Economics of Quality) Overall Fiscal Impact Roll up measures into a financial indicator such as: – Benefits/cost ratio: present worth of total benefits B/C= present worth of total costs If ratio is greater than 1, project deemed worthwhile and vise versa Overall Fiscal Impact con’t. OR: – Net present worth: NPW=present worth of total benefits – total worth of total costs – Simple number; positive worth indicates program is viable – Both ignore time value of money; relative to project not company as a whole Data Collection and Analysis Statistical analysis of QMS impact, design study based on answering some questions: 1. Important to answer implementing QMS vs. not implementing? Larger scope, need control group, different indicators 2. Does QMS implementation pay for itself? ** 3. How do AIB vs. ISO systems compare? 4. What is QMS impact over time? Repeated measures Regardless of above, 1. How to control location variation i.e. how were present locations picked for QMS implementation? Timeline Timeline Questions What is finish date? How long does data collection last? What are the resources at hand? Conclusion Answer questions of scope, design, particular measures, summarizing fiscal indicator(s), timeline Review relevant FC documents as necessary