Timber framing

advertisement

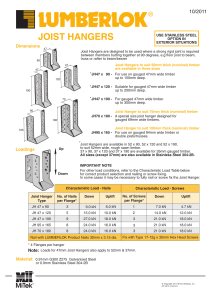

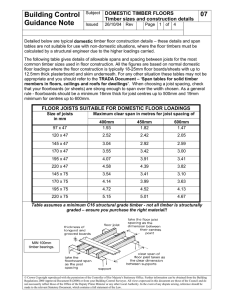

Lesson 11 Timber framed structures are common in New Zealand. They comprise of timber studs, plates, bearers, beams, rafters, purlins and custom fabrications at the connection points i.e joist hangers, bolts If the building is predominately timber framed a price can be sought for a prenail construction. This is where the frames are constructed off site and then installed as component elements. Alternatively the each piece of timber is measured and then priced on a unit rate estimate Small v large quantities Consider the overall project. There maybe lots of repetition but production rates can be affected by the complexity of the project and the connection details Geographic location Availability of material and delivery charges are affected by the location of the project. You must also consider if the material needs to be protected/ stored when it arrives on site Labour availability Skilled craftsmen are required to efficiently erect a timber framed structure. Need to consider availability of labour and travel times when pricing projects Seasonal affect on work Timber framed structures can be erected in all seasons however the weather can effect the method of installation and erection Excessive moisture may cause the effect the wood to swell making proper fitting difficult Hot dry weather lower moisture content and causes to shrink which causes connections to be excessively tight when moisture content is returned to the wood. Scope of works As an estimator you need to understand the full extent of the works. Consideration must be taken for phasing work, working with other trades, temporary utility locations and access. Calculating labour constants Depending on the labour constants used either price as individual rates or average cost per man hour Lead carpenter Carpenter (2 no) Labourer (2no) Total Average cost/man hour $55.00/hr $100.00/hr $56.00/hr $211.00/hr $42.20/hr Calculating These are typically sourced from timber merchants or the contractors main database. Special CSQ’s can be offered for larger projects. Calculating material costs equipment costs Most skilled carpenters will provide their own equipment ie nail guns, drop saws etc. However specialist equipment will either be costed under carpentry items or in the p & g section of the tender Example If the length and height of a wall is known and the centres of the studs are known then the quantity of timber can be calculated if the m2 area of the wall is the only item given The following method can be used for calculating the number of bolts or other connections Example The length of a wall = 20m The height is 3.0m The centres of the studs are at 600 c/c No of studs required are 3.0/.60 = 5+ 1 for the end TOTAL = 6 no studs Example If bolts are required at 1200 c/c along the base plate. Total no of bolts required 20/1.2 = 16.60 = 17 + 1 end = 18 no If joist hangers are required for rafters at 400 c/c along a roof line of 15m Example If joist hangers are required for rafters at 400 c/c along a roof line of 15m Total no of joist hangers 15/0.40 = 37.50 = 38 +1 end = 39 x 2 both ends Example If bolts are required at 1200 c/c along the base plate. Total no of bolts required 20/1.2 = 16.60 = 17 + 1 end = 18 no If joist hangers are required for rafters at 400 c/c along a roof line of 15m 100 x 50 timber joist fixed to timber plate Materials 100 x 50 $3.00/m Nails allow 2kg/m3 ($1.20 kg/m3) 2 x $1.2 x .05 x .1 $0.01/m Sub total $3.01/m Delivery say 5 % $0.15/m Sub total $3.16/m Wastage 7.5% $0.24/m Total $3.40/m 100 x 50 timber joist fixed to timber plate Labour 0.14 hr/m @ $42.20 = $5.98/m Total $9.31/m Other considerations Unloading and distributing is included in the labour rate or it is an additional item in the p&g section Nails are included in each individual unit rate or are allowed for as a percentage of the total carpentry costs (typically 10%) Delivery can be costed separately and not included in the unit rate Cost estimates are broken down into different sections. The main ones are trade or elements. Construction costs are segregated into these components for cost comparison or analysis. Understanding what each component comprises of helps to ensure that all items have been included in the cost estimate Summary of trade items Site preparation and Demolition Demoliton, shoring of existing buildings General site grading to required subgrades Removal and relocation of ultility lines Retaining walls to protect adjoining properties Foundations Excavation of site subgrade and disposal of excavated materials, backfilling and removal of surplus material All necessary temporary work to support the sides of the excavation and removal of ground water All pile caps, tie beams, trenches, pad foundations that are not part of the flooring system Vertical Structure All columns and structural walls with the roughest finish acceptable Any necessary fire proofing Floor and roof structure Floor slabs on grade including sand blinding and vapour barriers but not waterproof membranes All beams, trusses etc supported by the vertical structure Structural framing joist, rafters and decking of all supported floors and roof – rough structural finish only Necessary fire proofing Exterior Cladding Any non structural skin or curtain wall added to the structure to enclose or finish the building Any supporting framing or connections required for the cladding Any insulation Waterproofing or damp proof membranes above grade Non structural balconies, paparpet walls Fascias, decorative bands or friezes External window and doors/louvres including glazing and hardware Roofing and waterproofing Waterproof membranes on floors and walls including skylights Exterior and interior roofing insulation Exterior applied membranes All flashings and gutters/downpipes Interior partitions, doors and glazing Non load bearing partitions Sound insulation to partitions Balustrades, rails screens All interior doors and windows including glazing and hardware Floor, wall and ceiling finishes Floor coverings of all types Bases or skirtings including finish Any special finishes Suspended ceilings and insulation above ceiling Painting and other decorations Function Equipment and specialities Any built in shelving and cabinetry Protective guards and barriers Prefabricated compartments and accessories Stairs and vertical transportation Staircases and ramps complete with landings and balustrading Lifts and moving staircases/ramps Dumb waiters or hoists Plumbing system All sanitaryware and specialist plumbing items Waste,soil pipes connected to the inside and outside of the building Drainage including sewer systems Floor and roof drains and piping Water treatment and storage including circulation Heating, ventilation and air conditioning Heating, cooling and air cleaning equipment All pipework and ducting associated with the above Grills, dampers and exhaust fans Electrical systems Main service from transformers, switch gear, panels etc required for the building All lighting fixtures, wiring and power circuits Data cabling, sound and communication systems Emergency power BMS systems Fire protection system Automatic fire protection and sprinkler systems Site paving, structures and landscaping Retaining walls to support landscaping Paving and curbs Landscaping and irrigation Site furniture Fencing and rails Lighting and drainage Contractors overheads and profit P&G for the project – site establishment, storage facilities, supervision, temporary services, security insurance, bonds, permits Margin – contractors margin for the total cost of the project Contingency for design development Fluctuations