easi-joist Metal Web Floor System Technical Manual

advertisement

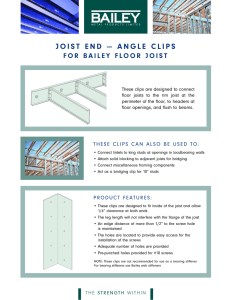

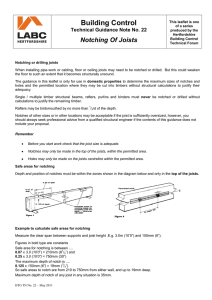

Metal Web Floor System Contents Contents Introduction and benefits easi-joist® definitions easi-joist webs 4 5-6 Mechanical services 7 Loading and design 8 Floor stiffness 2 3 9 Internal non-loadbearing wall 10 - 11 Typical support details 12 - 13 Two ply girder and trimmer details 14 Edge closer details for timber frame and Internal bearing 15 Strongback installation and horizontal restraint strap details 16 Typical timber frame compartment floor and party wall with service void detail 17 Layout, positioning and lifting 18 Flooring, fixing and fire resistance 19 I n t ro d u c t i o n a n d B e n e f i t s Introduction easi-joists are parallel chord trusses utilising stress graded timber chords “on Flat” or “on Edge”. These chords are plated together with a precision engineered and manufactured structural component called the metal web, these when combined form the easi-joist®. The easi-joist® combines the lightness of timber with the structural qualities of the metal web, together these two components offer an opportunity for designing commercial, domestic and industrial floor applications with spans equal to and exceeding traditional timber joists and there equivalent timber alternative, but with better damping and stiffness qualities. easi-joist® is a precision designed and manufactured floor system, that is designed to make floor joist manufacture faster, more cost effective and easier to install. Benefits • Open web design This allows for easier more practical installation of services including waste water pipes, electrical cabling, heating pipes and other services. • Reduced site wastage Precisely manufactured easi-joists virtually eliminate all site alterations this cuts out on waste and pilfering. • Light weight The combination of smaller timber sections with the light weight metal web means that finished product is lighter than timber and much lighter than timber equivalents. • Speed and ease of erection As the timber is generally used “on flat” the minimum 72mm width allows for a speedy set out prior to laying floor boards without the need for temporary bracing. • Top chord support The easi-joist® is not limited in it’s support capabilities options to support on the top chord are included. • Long term stability The reduced sections used in the manufacture of the easi-joist® combined with the metal web means; that less loss of moisture and shrinkage is seen meaning a quieter and longer lasting floor system. • Comparative with timber The easi-joist® system can be manufactured to the minimum depth required in the standard codes of practice. • Improved sound and vibration The metal web floor system allows for the installation of a rigid Strongback that reduces vibration and improves the overall performance of the floor. 3 easi-joist Definitions Top chord Top chord splice Column Metal Web End column Bottom chord Column plate Bottom chord splice Strongback Intermediate support End bearing 4 e a s i - j o i s t We b s 36mm easi-joist 600mm 199mm 35mm 195mm MS200 125mm 101mm 35mm 600mm 199mm 35mm 230mm MS250 160mm 101mm 35mm 600mm 199mm 35mm 280mm 101mm MS300 210mm 35mm 758mm 247mm 35mm MS400 105mm 393mm 323mm 35mm 5 e a s i - j o i s t We b s 47mm easi-joist 600mm 199mm 47mm 219mm MS200 125mm 101mm 47mm 600mm 199mm 47mm 254mm MS250 160mm 101mm 47mm 600mm 199mm 47mm 304mm 101mm MS300 210mm 47mm 758mm 247mm 47mm 105mm 417mm 323mm 47mm 6 MS400 Mechanical Services easi-joists are designed to allow for easy accommodation of electrical, plumbing, waste water and other services required within the floor joist area with no cutting or notching required. D A H W The chords for easi-joist must NEVER be cut, notched or drilled in any way without written approval by a Wolf Systems Ltd Engineer. Similarly the metal webs must NEVER be drilled, bent or removed for any reason. Clearance for services MS 200 MS 250 MS 300 MS 400 A (mm) 125 160 210 323 D (mm) 100 150 200 280 Clearance for rectangular services MS 200 MS 250 MS 300 MS 400 H mm W mm W mm W mm W mm 50 300 300 330 500 100 100 200 250 410 150 50 70 170 330 200 N/A N/A 70 250 250 N/A N/A N/A 170 300 N/A N/A N/A 70 7 Loading and Design Dead loads The weight of partition walls, floor cover, ceilings, self weight of joist and permanent services. Live loads (Imposed loads) Everything not nailed down, loads produced by the use and occupancy of the of the floor, the load assumed to be produced by the intended occupancy or use including the weight of movable partitions, distributed, concentrated, impact and inertia loads, but excluding wind loads. “It is essential that both distributed live loads and point live load requirements be considered independently for various types of floor loadings in accordance with the specific British Standard associated with floor loads – BS 6399: Part 1: 1996 incorporating amendment 1 (11/10/2002)” Dead loads Floor covering Permanent services Live loads The easi-joist Software program will allow the detailer/designer to specify the live loads applicable to each section of floor joist as these may alter according to the use of the floor. Any unusual loads that may be required for the floor system i.e. hoist loads, spa baths etc must be checked and written confirmation received from Wolf Systems Ltd before proceeding. Load warning easi-joists are not designed to support loadbearing walls. Any and all roof and beam loads are to be supported by external walls only, Written confirmation from Wolf Systems Ltd would be required in advance should evidence of the above load conditions be evident. Further to this any additional loads that may be imposed during construction e.g. temporary support of building materials that are likely to have higher loads than those the joists have been designed for must be included in the design loads. 8 Unusual loads Partition wall F l o o r S t i ff n e s s Factors affecting floor stiffness Factors affecting floor damping Strongback is sized, located and fixed correctly to the easi-joists. The dynamic action of any flooring system whether timber, concrete or steel is dependent on a number of factors such as the eventual floor plan, the applied loads and finally the level of expectation of the occupants. There are certain components of the building structure which act together and reduce vibration of the floor, this is known as damping. (Strongback grids are generally provided at the centre of each 4000mm span) One of the major contributors of the damping effect (which will essentially improve the easi-joist floor) is the Strongback. It is essential for both the structural integrity and performance of the easi-joist floor system that the Other factors that that assist in the damping effect are internal walls, this is because in larger open areas floors tend to have a more dynamic action. Other contributors are floor and ceiling covering and floor linings that are correctly screwed to the joists to reduce additional dynamic action present in the floor. Strongback posts can be inserted after erecting joists should additional Strongbacks be required Strongback Strongback grid designed to automatically position the Strongback correctly 9 I n t e r n a l N o n - l o a d b e a r i n g Wa l l s Correct installation of internal non-loadbearing walls (parallel) There are two accepted methods for internal non loadbearing walls that run parallel with the easi-joists themselves. In the case where fitted flooring will be used after the internal wall is constructed an additional easi-joist will required below this wall to support both the floor in addition to the wall. Walls that are parallel to the easi-joist must have noggins at 600mm centres between joists to support internal wall. Method 1 Wall panel screw nailed onto noggins with a minimum of 2 x 3.35 dia. galvanised nails (length to suit) 47 x 97 noggins at 600mm c/c Universal “Z” clip (or similar) Method 2 Internal non-loadbearing wall 10mm gap required for expansion and contraction of floor material Double easi-joist provided under wall to support floor material 10 I n t e r n a l N o n - l o a d b e a r i n g Wa l l s Correct installation of internal non-loadbearing walls (perpendicular) Again there are 2 accepted methods with internal non-loadbearing walls, placed perpendicular to the easi-joists these do not require additional support. Method 1: Platform floor Internal non-loadbearing wall easi-joist Method 2: Fitted floor No additional support required for fitted flooring with internal walls perpendicular to the easi-joists however a 10mm expansion gap is required between the floor boards and wall. Internal non-loadbearing wall 10mm gap required easi-joist 11 Ty p i c a l S u p p o r t D e t a i l s Bottom chord bearings Typical Support details for easi-joists include and are mainly joists on masonry hangers. The use of joist hangers reduces the likelihood of heat loss into the cavity and the transmission of sound through the separating walls. Joist hangers must always match the height of the joist being used, this ensures adequate lateral restraint, failure to comply will mean strapping each joist after erection. Joist /masonry hanger Concrete beam Joist to masonry hanger Hanger depth must match depth of joist Concrete Joist /masonry hanger Internal Joist to masonry hanger Hanger depth must match depth of joist Block work/brickwork Joist on timber frame Stud wall Flooring Ceiling lining Wall lining 12 Ty p i c a l S u p p o r t D e t a i l s Top chord bearings Joist on top chord Extended top chord on wallplate Flooring Ceiling Joist on I beam, hidden support Hidden Top chord support allows for continuous ceiling material. Continuous top chord Flooring Ceiling Joist on I beam Extended top chord Steel I beam 13 Tw o P l y G i rd e r a n d Tr i m m e r D e t a i l Two ply girder Two ply angles as specified by designer Extended hangers Trimmer detail Two ply angles as specified by designer Beam depth to suit, beam to be slotted through both joists Packing piece to maintain ceiling line 14 Edge Closer Detail for Timber Frame and Internal Bearing Edge closer detail for timber frame 50 mm 35mm edge closer prefabricated faced with plywood and including a 20mm lap at the top Lateral restraint detail 47 x 72 top chord restraint fixed to joists either between joists or attached to bottom chord web posts Head binder to joists Internal bearing 15 S t ro n g b a c k I n s t a l l a t i o n and Horizontal Restraint Strap Details Strongback sizes and installation easi-joist floor system and reducing the deflection by load sharing. Strongbacks are installed within the easi-joist at right angles and their purpose is to dampen the vibrations by increasing the stiffness of the Proper installation of the Strongback and flooring material will ultimately determine how well your easi-joist flooring system will work. m 0m 30 Fixing & splicing Strongbacks must be fixed to vertical webs in each easi-joist with 2 no 3.15 x 75mm Nails. Strongbacks may be spliced where required by using a 600mm section equally over joint and nailed using 6 no 3.15 x 42mm nails on either side of the join. Splice positioning and nailing positions 600mm Timber splice nailed by minimum 6 no nails either side Splice joint easi-joist Nominal Size Strongback size TR26 Grade Alternate Strongback Lower Grade MS200 72 X 35 TR26 97 X 35 C16 MS250 97 X 35 TR26 122 X 35 C16 MS300 122 X 35 TR26 142 X 35 C16 MS400 147 X35 TR26 172 X 35 C16 Horizontal restraint strap Horizontal bracing straps are required to be fixed to loadbearing walls perpendicular to easi-joists. This member must be continuous over a minimum of three easi-joists. 97 x 35/47mm twice nailed to brace using 3.15 x 75mm long galvanised nails Strap fixed with minimum of four fixings of which at least one is to be over the third joist 16 Ty p i c a l T i m b e r F r a m e C o m p a r t m e n t F l o o r Service void 5mm (min) foamed polyethylene resilient flanking strip resilient layer easi-joist parallel to wall easi-joist bearing on wall 20 0 ap mm pro x Installation of insulation 100m mineral wool insulation quilt 23 kg/m2 Mineral wool cavity barrier 17 Layout, Positioning & Lifting easi-joists typically placed perpendicular to loadbearing walls. Care should be taken to ensure that the correct spacing between the easi-joists as designed and indicated on the layout is maintained throughout. Never exceed design spacing. Correct The correct bearing should also be maintained on every easi-joist as specified. Wrong Lifting easi-joists may be lifted in either single units or packs but care should be taken to eliminate twisting, buckling, bending and dropping of the Joists, Slings should always be attached to the Timber Chord where a panel point occurs. 18 45 F l o o r i n g , F i x i n g a n d F i re R e s i s t a n c e Flooring and fixing Explanation There are many different types of floor decking available the most commonly used is pre-cut chipboard in standard sizes, thickness may vary from 18 to 22mm depending on the spacing of the easi-joist®. Any special instructions as indicated by the manufacturers should be noted. Basic guidelines Chipboard utilised in domestic flooring should be as per BS currently used for solid timber equivalents. Tongue and grooved boards should be laid with the long edges running perpendicular to the joists with joints between the short edges occurring on the centreline of the joist. Square edged boards need to be supported continuously along all edges. Joints along short edge boards should be staggered and the length of any board should generally not be less than 2 x joist centres. It is essential for a silent floor that boards are supported with 50mm of their edges at the perimeter of the floor by either joist or perimeter noggin. Fixings shall be of a minimum length equal to 2.5 x board thickness nails/screws should be positioned 8mm from board edge and 200mm c/c along all supports and edges. Chipboard is similar to other products in that it expands and contracts when exposed to high humidity, therefore it is recommended that a 10-12mm expansion gap left between the boards and the face of the brickwork. Further to this a 2mm gap is recommended between abutting boards. Part E sound Fire resistance Tests are currently underway to ascertain the minimum requirement to ensure that the requirements Part E are met fully. Wolf Systems suggest that the details that currently apply for solid joists which we assume to be "worst case scenario", should be utilised until such time as specific robust details are approved and agreed by local authorities. All floors manufactured utilising elements of timber rely on a contribution from the ceiling for overall fire resistance. Party floors require a minimum of 2 No 12mm Plasterboard to maintain the standard fire regulations. Standard domestic flooring requires minimum of 1 No 12mm Plasterboard. The requirements for fire resistance in domestic floors structures is 30 minutes and for party floors is 60 minutes. Full scale fire testing will be initiated to comply with European standards for the easi-joist®, however for the purpose of this initial manual it is recommended that you utilise a “Worst case scenario” Being a solid timber joist and therefore strict adherence to BS 5268: Part 4, Section 2.1 is required. Ceiling boards are to be positioned such as their long edges run perpendicular to the easi-joists. The boards are fixed to the underside of the joist using 3.2mm x 42mm long approved fire resistant screws positioned at 150mm centres. Joints that do not occur at a joist should be backed with a 75mm wide strip of plasterboard of the same type and thickness as the ceiling board screw centres to be minimum 150mm centres. All joints must be taped with an approved fire resistant 50mm wide fibre tape and filled with an approved filler. No apertures or service penetrations should be present except where fitted with an improved fire resistant fitting (lights etc) or an appropriate fire sealing system. 19 Wolf Systems Limited Shilton Industrial Estate, Shilton, Coventry CV7 9QL T 08707 33 99 33 F 08707 33 99 55 E easi-joist@wolfsystem.co.uk web site www.wolfsystem.co.uk