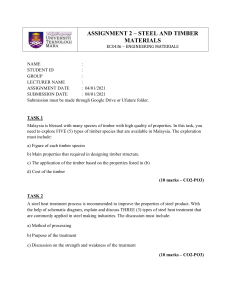

Student Notes on Timber Framed Construction

advertisement

Unit 6/P6 – Timber Frame Construction • Premade timber walls provide main support of structure. • Often set on a raft foundation • Less tolerance for uneven floor than in traditional and concrete construction • Inner wall is made from stud wall nailed to sheets of woods. • 100mm x 50mm studs on to 18mm ply • Void filled with insulation • These are bolted down to the concrete floor with an expansion bolt. • Factory prefabrication guarantees quality and no weather delays. • Less time on site • Crane required • Windows and door opening pre-planned so less chance for on-sight error. • Out leaf or external wall normally brick and is non-load bearing. • Provides insulation and weatherproofing. • Roof is normally truss work, slate or tile. Name ________________ Unit 6/P6 – Timber Frame Construction • Internal walls are non load bearing or stud wall. • Plasterboard as per traditional construction. • Vapour seal • Timber is treated • Fire resistant • Dry Rot • First floor is suspended timber floor, can be internal or sandwhiched between floors • Known for energy efficiency • Condensation is likely to form in the cavity so a moisture barrier or vapour check is used on the internal wall. • Services are run through walls and foundations as per a traditional building • Stairs and windows made off site and fitted. Name ________________ Unit 6/P6 – Timber Frame Construction Name ________________