Ajax is about to embark on a project involving the

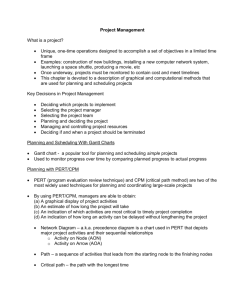

Project Scheduling Techniques

Ajax is about to embark on a project involving the design, manufacture and introduction of a new microwave oven. The first three activities and the immediate predecessors are:

Activity Predecessor

A Prototype Design none

B Acquisition of Materials A

C Prototype Construction B

However, it has not yet been decided whether the prototype materials will be purchased from a vendor (taking two weeks) or produced in another Ajax division (four weeks). What are the implications of this regarding usage of any standard project scheduling technique? Respond to at least two of your classmates’ postings.

In this discussion post, we are asked to discuss the implications of using an outside vendor versus an internal vendor in regards the usage of a standard project scheduling technique for Ajax’s new microwave oven. We are provided the given Activity

Predecessor:

Activity Predecessor:

A Prototype Design (none)

B Acquisition of Materials (A)

C Prototype Construction (B)

As we can see, Activity (A) is to design the prototype of the new product. This activity is not preceded by any other activity, thus it does not have any predecessor. In this activity, the company determines the look and feel of the new product and in this discussion post, the most important part of this step is that it identifies the required components and materials of the prototype design.

The next Activity (B) is the acquisition of materials and cannot be started until

Activity (A) is completed, so this identifies Activity B being dependent of Activity

A. Finally, Activity (C) is the construction of the prototype which will not take place prior to the completion of Activity (B), if there are not any materials, there cannot be any construction; so Activity B is a predecessor to Activity C.

Providing the Ajax company is using the CPM/PERT process, they have completed the first steps of identifying all the major activities of the project and any predecessors along with the critical path which determines longest path in the network and the minimal completion time of the project. What has not been determined is the time allocated to each activity, the time the in which project must be completed, and any budgetary constraints. Various options such as PERT/Cost, completion time analysis, or a budget analysis can be implemented to complete the project in the defined time period and budgetary guidelines.

Additional considerations management must evaluate, having to wait two more weeks for an internal supplier may be advantageous because the materials purchased from an internal Ajax division may have less costs, management will have greater control over the supply process, and the company will retain knowledge if manufacturing relies on technologies developed in-house (Martin, 2013). If the company chooses to outsource their material supplies, the project manager has the option to leverage competitiveness amongst the market to drive the best deal in terms of speed, price, and the formation of new business partners for future dealings (Martin, 2013).

Ultimately, prior to moving on in the CPM/PERT process, the project manager must acquire the missing pieces of information before being able to further develop the model.

Reference

Lawrence, J., and Pasternack, B. (2002). Applied Management Science (2nd Edition).

John Wiley and Sons, Inc.

Martin, M. (2013). The Advantages & Disadvantages of Sourcing Methods of Project

Managers, Houston Chronicle, Retrieved from: http://smallbusiness.chron.com/advantages-disadvantages-sourcing-methods-projectmanagers-35755.html