Supply Chain Management

advertisement

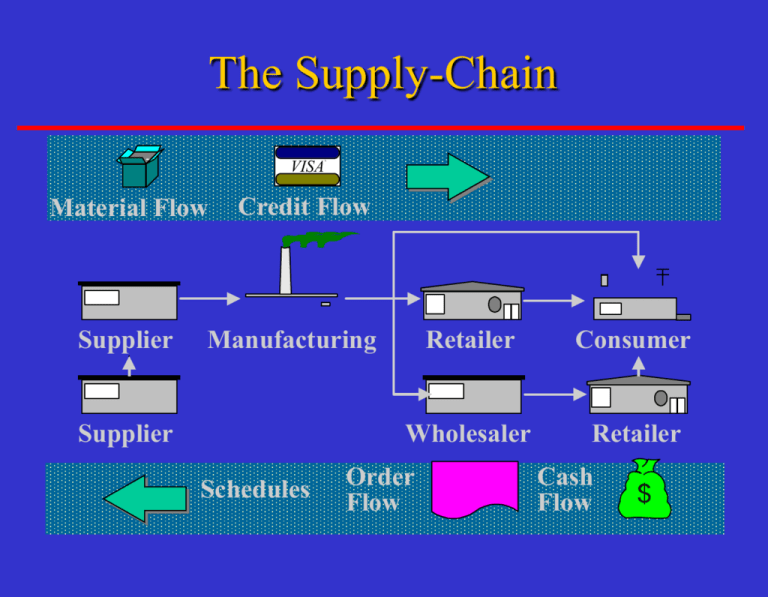

The Supply-Chain VISA Material Flow Supplier ® Credit Flow Manufacturing Supplier Schedules Retailer Consumer Wholesaler Retailer Order Flow Cash Flow Supply-Chain Management ¨ Planning, organizing, directing, & controlling flows of materials Begins with raw materials ¨ Continues through internal operations ¨ Ends with distribution of finished goods ¨ ¨ Involves everyone in supply-chain ¨ Example: Your supplier’s supplier ¨ Objective: Maximize value & lower waste The Supply Chain Market research data scheduling information Engineering and design data Order flow and cash flow Supplier Inventory Supplier Customer Ideas and design to satisfy end customer Material flow Credit flow Customer Manufacturer Inventory Inventory Supplier Distributor Inventory Customer Supply Chain Management ¨ SCM is primarily concerned with the efficient integration of suppliers, factories, warehouses and stores so that merchandise is produced and distributed in the right quantities, to the right locations and at the right time, and so as to minimize total system cost subject to satisfying service requirements. Conflicting Objectives in SC ¨ Purchasing ¨ ¨ ¨ ¨ stable volume requirements flexible delivery time little variation in mix large quantities ¨ Manufacturing ¨ ¨ ¨ ¨ long run production high quality high productivity low production cost Conflicting Objectives in SC ¨ Warehousing ¨ ¨ ¨ low inventory reduced transportation costs quick replenishment capability ¨ Customers ¨ ¨ ¨ ¨ short order lead time high in stock enormous variety in products low prices Material Costs in Supply-Chain Wholesale Manufacturing 8% 9% COGS Payroll 31% 11% 58% 83% Material Other Dir. Wages Other Retail 13% Source: U.S. Department of Commerce, Bureau of Census, 1987 Census of Manufacturers: General Summary of Retail Trade (Washington, D.C.: Government Printing Office, 1991) 16% COGS Payroll 71% Other Supply-Chain Support for Overall Strategy Low Cost Response Differentiation Supplier’s goal Supply demand at lowest possible cost Respond quickly to changing requirements and demand to minimize stockouts Share market research; jointly develop products and options Primary Selection Criteria Select primarily for cost Select primarily for capacity, speed, and flexibility Select primarily for product development skills Supply-Chain Support for Overall Strategy - continued Low Cost Response Differentiation Process Characteristics Maintain high average utilization Invest in excess capacity and flexible processes Modular processes to lend themselves to mass customization Inventory Characteristics Minimize inventory throughout the chain to hold down costs Develop responsive system, with buffer stocks positioned to ensure supply Minimize inventory in the chain to avoid obsolescence Supply-Chain Support for Overall Strategy - continued Low Cost Response Differentiation Lead-time Characteristics Shorten leadtime as long as it does not increase costs Invest aggressively to reduce production lead-time Invest aggressively to reduce development lead-time Product-design Characteristics Maximize performance and minimize cost Use product designs that lead to low set-up time and rapid production ramp-up Use modular design to postpone product differentiation for as long as possible Global Supply-Chain Issues Supply chains in a global environment must be: flexible enough to react to sudden changes in parts availability, distribution, or shipping channels, import duties, and currency rates ¨ able to use the latest computer and transmission technologies to manage the shipment of parts in and finished products out ¨ staffed with local specialists to handle duties, trade, freight, customs and political issues ¨ Purchasing ¨ Acquisition of goods & services ¨ Activities Help decide whether to make or buy ¨ Identify sources of supply ¨ Select suppliers & negotiate contracts ¨ Control vendor performance ¨ ¨ Importance ¨ ¨ Major cost center Affects quality of final product Purchasing Costs as a Percent of Sales Industry ¨ ¨ ¨ ¨ ¨ ¨ ¨ All industry Automobile Food Lumber Paper Petroleum Transportation Percent of Sales ¨ ¨ ¨ ¨ ¨ ¨ ¨ 52% 61% 60% 61% 55% 74% 63% Objectives of the Purchasing Function ¨ Help identify the products and services that can be best obtained externally; and ¨ Develop, evaluate, and determine the best supplier, price, and delivery for those products and services Purchasing Techniques ¨ ¨ ¨ ¨ ¨ ¨ ¨ Drop shipping and special packaging Blanket orders Invoiceless purchasing Electronic ordering and funds transfer Electronic data interchange (EDI) Stockless purchasing Standardization Make/Buy Considerations Reasons for Making Reasons for Buying ¨ ¨ ¨ ¨ ¨ ¨ ¨ ¨ ¨ ¨ ¨ ¨ ¨ lower production cost unsuitable suppliers assure adequate supply utilize surplus labor and make a marginal contribution obtain desired quantity remove supplier collusion obtain a unique item that would entail a prohibitive commitment from the supplier maintain organizational talent protect proprietary design or quality increase/maintain size of company ¨ ¨ ¨ ¨ ¨ ¨ lower acquisition cost preserve supplier commitment obtain technical or management ability inadequate capacity reduce inventory costs ensure flexibility and alternate source of supply reciprocity item is protected by patent or trade secret frees management to deal with its primary business Supply-Chain Strategies ¨ Negotiate with many suppliers; play one supplier against another ¨ Develop long-term “partnering” arrangements with a few suppliers who will work with you to satisfy the end customer ¨ Vertically integrate; buy the actual supplier ¨ Keiretsu - have your suppliers become part of a company coalition ¨ Create a virtual company that uses suppliers on an as-needed basis. Many Suppliers Strategy ¨ ¨ ¨ ¨ ¨ ¨ ¨ ¨ Many sources per item Adversarial relationship Short-term Little openness Negotiated, sporadic PO’s High prices Infrequent, large lots Delivery to receiving dock © 1995 Corel Corp. Few Suppliers Strategy ¨ ¨ ¨ ¨ ¨ ¨ ¨ ¨ 1 or few sources per item Partnership (JIT) Long-term, stable On-site audits & visits Exclusive contracts Low prices (large orders) Frequent, small lots Delivery to point of use © 1995 Corel Corp. Supplier Selection Criteria ¨ Company ¨ ¨ ¨ Financial stability Management Location ¨ Product Quality ¨ Price ¨ ¨ Service Delivery on time ¨ Condition on arrival ¨ Technical support ¨ Training ¨ Managing the Supply-Chain ¨ Options: Postponement ¨ Channel assembly ¨ Drop shipping ¨ Blanket orders ¨ Invoiceless purchasing ¨ Electronic ordering and funds transfer ¨ Stockless purchasing ¨ Standardization ¨ Managing the Supply-Chain Other Options ¨ Establishing lines of credit for suppliers ¨ Reducing bank “float” ¨ Coordinating production and shipping schedules with suppliers and distributors ¨ Sharing market research ¨ Making optimal use of warehouse space Materials Management ¨ Integrates all materials functions Purchasing ¨ Inventory management ¨ Production control ¨ Inbound traffic ¨ Warehousing and stores ¨ Incoming quality control ¨ ¨ Objective: Efficient, low cost operations Goods Movement Options ¨ ¨ ¨ ¨ ¨ Trucking Railways Airfreight Waterways Pipelines