Document

advertisement

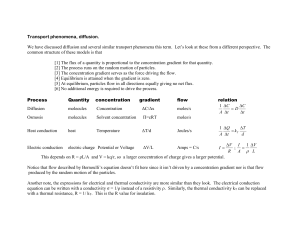

Engineering 45 Materials of Engineering Lecture 8 - Diffusion Review & Thermal Properties Carlos Casillas, PE 16-Jan-12 Licensed Chemical Engineer Spring 2012 Subtitle or main author’s name CCasillas@ChabotCollege.edu Hayward, CA Recruitment • Click to edit Master text styles – Second level • Third level – Fourth level » Fifth level Other Types of Diffusion (Beside Mass or Atomic) • Flux is general concept: e.g. charges, phonons,.. • Charge Flux – jq 1 dq 1 d(Ne) A dt A dt Defining conductivity (a material property) Ohm’s Law dV j dx I 1V V jq A AR l • Heat Flux – (by phonons) Q 1 dH 1 d(N ) A dt A dt dT Q dx Defining thermal conductivity (a material property) Or w/ Thermal Diffusivity: h cV Q cV T e = electric chg. N = net # e- cross A Solution: Fick’s 2nd Law x Vx Vs erf V0 Vs 2 t N = # of phonons with avg. energy Solution: Fick’s 2nd Law x Tx Ts erf T0 Ts 2 ht Diffusion- Steady and Non-Steady State Diffusion - Mass transport by atomic motion Mechanisms • Gases & Liquids – random (Brownian) motion • Solids – vacancy diffusion or interstitial diffusion Substitution-diffusion:vacancies and interstitials • applies to substitutional impurities • atoms exchange with vacancies • rate depends on (1) number of vacancies; (2) activation energy to exchange. Number (or concentration*) of Vacancies at T E ni ci e N k T B • kBT gives eV E is an activation energy for a particular process (in J/mol, cal/mol, eV/atom). Where can we use Fick’s Law? Fick's law is commonly used to model transport processes in • food processing, • chemical protective clothing, • biopolymers, synthetic polymer membranes (fluid sepaations), • pharmaceuticals (controlled-release), • porous soils & solids, catalysts, nuclear isotope enrichment, • vapor & liquid thin-film coating & doping process, etc. Example The total membrane surface area in the lungs (alveoli) may be on the order of 100 square meters and have a thickness of less than a millionth of a meter, so it is a very effective gas-exchange interface. CO2 in air has D~16 mm2/s, and, in water, D~ 0.0016 mm2/s Gas Diffusion in Polymers Polymer Membrane Structure Modeling rate of diffusion: flux • Flux: • Directional Quantity • Flux can be measured for: - vacancies - host (A) atoms - impurity (B) atoms A = Area of flow • Empirically determined: – Make thin membrane of known surface area – Impose concentration gradient – Measure how fast atoms or molecules diffuse through the membrane diffused mass M J slope time Steady-state Diffusion: J ~ gradient of C • Concentration Profile, C(x): [kg/m3] Cu flux Ni flux Concentration of Cu [kg/m 3] Adapted from Fig. 6.2(c) Concentration of Ni [kg/m 3] Position, x • Fick's First Law: D is a constant • The steeper the concentration profile, the greater the flux Steady-State Diffusion • Steady State: concentration profile not changing with time. • Apply Fick's First Law: • If Jx)left = Jx)right , then dC J x D dx dC dC dx left dx right • Result: the slope, dC/dx, must be constant (i.e., slope doesn't vary with position) Steady-State Diffusion Rate of diffusion independent of time dC J~ dx Fick’s first law of diffusion C1 C1 C2 x1 x C2 x2 dC C C2 C1 if linear dx x x2 x1 dC J D dx D diffusion coefficient Example: Chemical Protective Clothing • Methylene chloride is a common ingredient of paint removers. Besides being an irritant, it also may be absorbed through skin. When using, protective gloves should be worn. • If butyl rubber gloves (0.04 cm thick) are used, what is the diffusive flux of methylene chloride through the glove? • Data: – D in butyl rubber: D = 110 x10-8 cm2/s C1 = 0.44 g/cm3 C = 0.02 g/cm3 – surface concentrations: 2 – Diffusion distance: x2 – x1 = 0.04 cm glove C1 paint remover tb 2 skin 6D C2 x1 x2 Jx = -D C2 - C1 x 2 - x1 = 1.16 x 10-5 g cm2 s Non-Steady-State Diffusion • Concentration profile, C(x), changes w/ time. • To conserve matter: • Governing Eqn. Fick’s 2nd Law: • Fick's First Law: Simple Diffusion expt • Glass tube filled with water. • At time t = 0, add some drops of ink to one end of the tube. • Measure the diffusion distance, x, over some time. • Compare the results with theory. Non-Steady-State Diffusion: another look • Concentration profile, C(x), changes w/ time. • Rate of accumulation C(x) C dx J x J xdx t • Using Fick’s Law: • If D is constant: C J x J x dx J x (J x dx) dx t x x C J x C D t x x x Fick's Second "Law" c t x Fick’s 2nd Law D c x D c x 2 2 Non-Steady-State Diffusion: C = c(x,t) concentration of diffusing species is a function of both t and position x c Fick's Second "Law" c D t x 2 2 • Copper diffuses into a bar of aluminum. Cs B.C. at t = 0, C = Co for 0 x at t > 0, C = CS for x = 0 (fixed surface conc.) C = Co for x = Adapted from Fig. 6.5, Callister & Rethwisch 3e. Non-Steady-State Diffusion CS • Cu diffuses into a bar of Al. C(x,t) Fick's Second "Law": c t D c x 2 2 Co • Solution: "error function” Values found in Table 5.1 erf (z) 2 z e 0 y 2 dy Example: Non-Steady-State Diffusion FCC iron-carbon alloy initially containing 0.20 wt% C is carburized at an elevated temperature and in an atmosphere that gives a surface C content at 1.0 wt%. If after 49.5 h the concentration of carbon is 0.35 wt% at a position 4.0 mm below the surface, what temperature was treatment done? Solution C( x, t ) Co 0.35 0.20 x 1 erf 1 erf ( z ) Cs Co 1.0 0.20 2 Dt Using Table 6.1 find z where erf(z) = 0.8125. Use interpolation. z 0.90 0.8125 0.7970 0.95 0.90 0.8209 0.7970 Now solve for D x z 2 Dt So, z 0.93 D erf(z) = 0.8125 z erf(z) 0.90 z 0.95 0.7970 0.8125 0.8209 x2 4 z 2t x2 (4 x 103 m)2 1h 11 2 D 2 2.6 x 10 m /s 2 4z t (4)(0.93) (49.5 h) 3600 s Solution (cont.): • To solve for the temperature at which D has the above value, we use a rearranged form of Equation (6.9a); D=D0 exp(-Qd/RT) • From Table 6.2, for diffusion of C in FCC Fe Do = 2.3 x 10-5 m2/s Qd = 148,000 J/mol Qd T R(lnDo lnD) D 2.6 x 1011 m2 /s 148,000 J/mol T (8.314 J/mol-K)(ln 2.3x105 m2 /s ln 2.6x1011 m2 /s) T = 1300 K = 1027°C Example: Processing • Copper diffuses into a bar of aluminum. • 10 hours processed at 600 C gives desired C(x). • How many hours needed to get the same C(x) at 500 C? Key point 1: C(x,t500C) = C(x,t600C). Key point 2: Both cases have the same Co and Cs. • Result: Dt should be held constant. C(x,t) Co Cs Co • Answer: x 1 erf 2 Dt Note D(T) are T dependent Values of D are provided. Example: At 300ºC the diffusion coefficient and activation energy for Cu in Si are D(300ºC) = 7.8 x 10-11 m2/s Qd = 41.5 kJ/mol What is the diffusion coefficient at 350ºC? transform data D Temp = T 1 and T2 Q D lnD2 lnD1 ln 2 d D1 R Qd lnD2 lnD0 R ln D 1/T Qd lnD1 lnD0 R 1 1 T2 T1 1 T1 22 Example (cont.) Qd D2 D1 exp R 1 1 T2 T1 T1 = 273 + 300 = 573 K T2 = 273 + 350 = 623 K D2 (7.8 x 10 11 41,500 J/mol 1 1 m /s) exp 8.314 J/mol - K 623 K 573 K 2 D2 = 15.7 x 10-11 m2/s 23 VMSE: Student Companion Site Diffusion Computations & Data Plots 24 Non-steady State Diffusion • Sample Problem: An FCC iron-carbon alloy initially containing 0.20 wt% C is carburized at an elevated temperature and in an atmosphere that gives a surface carbon concentration constant at 1.0 wt%. If after 49.5 h the concentration of carbon is 0.35 wt% at a position 4.0 mm below the surface, determine the temperature at which the treatment was carried out. • Solution: use Eqn. 5.5 C( x, t ) Co x 1 erf Cs Co 2 Dt 25 Solution (cont.): C( x , t ) Co x 1 erf Cs Co 2 Dt – t = 49.5 h – Cx = 0.35 wt% – Co = 0.20 wt% x = 4 x 10-3 m Cs = 1.0 wt% C( x, t ) Co 0.35 0.20 x 1 erf 1 erf ( z ) Cs Co 1.0 0.20 2 Dt erf(z) = 0.8125 26 Solution (cont.): We must now determine from Table 5.1 the value of z for which the error function is 0.8125. An interpolation is necessary as follows z erf(z) 0.90 z 0.95 0.7970 0.8125 0.8209 Now solve for D z 0.90 0.8125 0.7970 0.95 0.90 0.8209 0.7970 z 0.93 x z 2 Dt D x2 4 z 2t 3 2 x2 ( 4 x 10 m) 1h D 2.6 x 10 11 m2 /s 4z 2t ( 4)(0.93)2 ( 49.5 h) 3600 s 27 Solution (cont.): • To solve for the temperature at which D has the above value, we use a rearranged form of Equation (5.9a); Qd T R(lnDo lnD) from Table 5.2, for diffusion of C in FCC Fe Do = 2.3 x 10-5 m2/s Qd = 148,000 J/mol T 148,000 J/mol (8.314 J/mol - K)(ln 2.3x105 m2 /s ln 2.6x10 11 m2 /s) T = 1300 K = 1027ºC 28 Example: Chemical Protective Clothing (CPC) • Methylene chloride is a common ingredient of paint removers. Besides being an irritant, it also may be absorbed through skin. When using this paint remover, protective gloves should be worn. • If butyl rubber gloves (0.04 cm thick) are used, what is the breakthrough time (tb), i.e., how long could the gloves be used before methylene chloride reaches the hand? • Data – diffusion coefficient in butyl rubber: D = 110 x10-8 cm2/s 29 CPC Example (cont.) • Solution – assuming linear conc. gradient Breakthrough time = tb glove C1 paint remover 2 tb 6D skin C2 Equation from online CPC Case Study 5 at the Student Companion Site for Callister & Rethwisch 8e (www.wiley.com/ college/callister) x2 x1 0.04 cm x1 x2 D = 110 x 10-8 cm2/s tb (0.04 cm) 2 (6)(110 x 10 -8 2 240 s 4 min cm /s) Time required for breakthrough ca. 4 min 30 Summary Diffusion FASTER for... Diffusion SLOWER for... • open crystal structures • close-packed structures • materials w/secondary bonding • materials w/covalent bonding • smaller diffusing atoms • larger diffusing atoms • lower density materials • higher density materials 31 Chapter 19 Thermal Properties • Response of materials to the application of heat • As a material absorbs energy in the form of heat, its temperature rises and its dimensions increase. • This dimensional change is different for different materials. • Also, the ability to transfer heat by conduction varies greatly between materials. • How metals, ceramics, and polymers rank in hi-temp applications • Important concepts: – – – – heat capacity (C) thermal expansion (a) thermal conductivity (k) thermal shock resistance (TSR) Heat Capacity (Specific Heat) • The ability of a material to absorb heat is specified by its heat capacity, C • Cp = heat capacity measured @ constant pressure • Cv = heat capacity measured @ constant volume • Heat capacity is proportional to the amount of energy required to produce a unit of temperature change in a specified amount of material (Will measure in Lab3) heat capacity (J/mol-K) dQ C dT energy input (J/mol or J/kg) temperature change (K) • The specific heat (lower case c) describes the heat capacity per unit mass (Joules/kg-K) Materials Comparison of cp and C @ 298K (Lab3 set up) Battery Insulation Cv as Function of Temperature • Cv The vibrational contribution to heat capacity varies as a function of temperature for a crystalline solid – Increases with Increasing T – Tends to a limiting value of 3R = 24.93 J/mol-k 3R=24.93 Cv as Function of Temp cont • For Many Crystalline Solids Cv AT 3 : T TD Cv Cv , HiT C p const : T TD • Where – A Material Dependent CONSTANT – TD Debye Temperature, K Thermal Physics • Energy is Stored in Lattice Vibration Waves Called Phonons – Analogous to Optical PHOTONS Atomic Vibrations Atomic vibrations are in the form of lattice waves or phonons • Vibrations become coordinated & produce elastic waves that propagate through the solid • Waves have specific wavelengths and energies characteristic of the material – i.e., they are quantized • A single quantum of vibrational energy is a phonon • Phonons are responsible for the transport of energy by thermal conduction Adapted from Fig. 19.1, Callister & Rethwisch 8e. 37 Specific Heat: Comparison increasing cp Material • Polymers Polypropylene Polyethylene Polystyrene Teflon cp (J/kg-K) at room T 1925 1850 1170 1050 • Ceramics Magnesia (MgO) Alumina (Al2O3) Glass 940 775 840 • Metals Aluminum Steel Tungsten Gold 900 486 138 128 cp (specific heat): (J/kg-K) Cp (heat capacity): (J/mol-K) • Why is cp significantly larger for polymers? Selected values from Table 19.1, Callister & Rethwisch 8e. 38 Thermal Expansion • Concept Materials Change Size When Heated L final Linit Linit T final Tinit Linit Lfinal Tinit Tfinal Coefficient of Thermal Expansion • T↑ E↑ • ri is at the Statistical Avg of the Trough Width increasing T Bond energy r(T1) r(T5) due to Asymmetry of PE InterAtomic Distance Trough T5 T1 Bond length (r) Bond-energy vs bond-length curve is “asymmetric Coefficient of Thermal Expansion: Comparison Material increasing • Polymers Polypropylene Polyethylene Polystyrene Teflon • Metals Aluminum Steel Tungsten Gold • Ceramics Magnesia (MgO) Alumina (Al2O3) Soda-lime glass Silica (cryst. SiO2) (10-6/C) at room T 145-180 106-198 90-150 126-216 23.6 12 4.5 14.2 13.5 7.6 9 0.4 Why do Polymers have larger values? • Q: Why does generally decrease with increasing bond energy? Selected values from Table 19.1, Callister & Rethwisch 8e. 40 Thermal Conductivity • Concept Ability of a solid to transport heat from high to low temperature regions atomic vibrations and free electrons • Consider a Cold←Hot Bar T2 > T1 T1 x1 heat flux Heat Flux given by Fourier’s Law Heat flux (W/m2) or (J/m2-s) dT q k dx Thermal conductivity (W/m-K) or (J/m-K-s) x2 Temperature Gradient (K/m) • Q: Why the NEGATIVE Sign before k? Thermal Conductivity: Comparison Material k (W/m-K) Energy Transfer • Metals increasing k Aluminum Steel Tungsten Gold 247 52 178 315 By vibration of atoms and motion of electrons 38 39 1.7 1.4 By vibration of atoms • Ceramics Magnesia (MgO) Alumina (Al2O3) Soda-lime glass Silica (cryst. SiO2) • Polymers Polypropylene Polyethylene Polystyrene Teflon By vibration/ 0.12 0.46-0.50 rotation of chain molecules 0.13 0.25 Thermal Stresses • As Noted Previously a Material’s Tendency to Expand/Contract is Characterized by α • If a Heated/Cooled Material is Restrained to its Original Shape, then Thermal Stresses will Develop within the material • For a Solid Material • Where – – – – E l / lo Stress (Pa or typically MPa) E Modulus of Elasticity; a.k.a., Young’s Modulus (GPa) l Change in Length due to the Application of a force (m) lo Original, Unloaded Length (m) Thermal Stresses con’t Thermal Stresses cont. l / lo T • From Before Sub l/l into Young’s Modulus Eqn To Determine the Thermal Stress Relation E T Eample: a 1” Round 7075-T6 Al (5.6Zn, 2.5Mg, 1.6Cu, 0.23Cr wt%’s) Bar Must be Compressed by a 8200 lb force when restrained and Heated from Room Temp (295K) • Find The Avg Temperature for the Bar Thermal Stress Example • Find Stress F 8200lb 8200lb 2 A d 4 1in 2 4 F 10 440 psi 72MPa A Recall the Thermal Stress Eqn E T Need E & α • Consult Matls Ref 0 lbs 8200 lbs E = 10.4 Mpsi = 71.7 GPa α = 13.5 µin/in-°F = 13.5 µm/m-°F Thermal Stress Example cont • Solve Thermal Stress Reln for ΔT T E 0 lbs 8200 lbs 72 106 Pa T 71.7 109 Pa 13.5 10 6 / F T 74.4 F 41.3K Since The Bar was Originally at Room Temp T f Ti T T f 297 41 338 K T f 65C 150 F • Heating to Hot-Coffee Temps Produces Stresses That are about 2/3 of the Yield Strength (15 Ksi) Thermal Shock Resistance • Occurs due to: uneven heating/cooling. • Ex: Assume top thin layer is rapidly cooled from T1 to T2: rapid quench tries to contract during cooling T2 doesn’t want to contract T1 Temperature difference that can be produced by cooling: quenchrate (T1 T2 ) k Tension develops at surface E (T1 T2 ) Critical temperature difference for fracture (set = f) f (T1 T2 ) fracture E set equal fk TSR • Result: (quenchrate) for fracture E Thermal Shock Resistance con’t TSR – Physical Meaning • The Reln fk TSR E For Improved (GREATER) TSR want • σf↑ Material can withstand higher thermally-generated stress before fracture • k↑ Hi-Conductivity results in SMALLER Temperature Gradients; i.e., lower ΔT • E↓ More FLEXIBLE Material so the thermal stress from a given thermal strain will be reduced (σ = Eε) • α↓ Better Dimensional Stability; i.e., fewer restraining forces developed Thermal Protection System Re-entry T Distribution • Application: Space Shuttle Orbiter reinf C-C silica tiles (1650ºC) (400-1260ºC) Chapter-opening photograph, Chapter 23, Callister 5e (courtesy of the National Aeronautics and Space Administration.) • Silica tiles (400-1260ºC): -- large scale application Fig. 19.3W, Callister 5e. (Fig. 19.3W courtesy the National Aeronautics and Space Administration.) nylon felt, silicon rubber coating (400ºC) Fig. 19.2W, Callister 6e. (Fig. 19.2W adapted from L.J. Korb, C.A. Morant, R.M. Calland, and C.S. Thatcher, "The Shuttle Orbiter Thermal Protection System", Ceramic Bulletin, No. 11, Nov. 1981, p. 1189.) -- microstructure: ~90% porosity! Silica fibers bonded to one another during heat treatment. 100 mm Fig. 19.4W, Callister 5e. (Fig. 219.4W courtesy Lockheed Aerospace Ceramics Systems, Sunnyvale, CA.) 51 WhiteBoard Work • Problem 19.5 – Debye Temperature Charles Kittel, “Introduction to Solid State Physics”, 6e, John Wiley & Sons, 1986. pg-110