Critique of the Quality Pioneers

advertisement

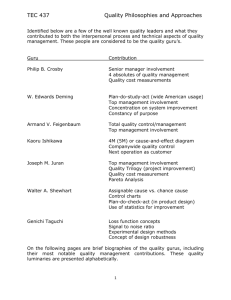

MOREHEAD STATE UNIVERSITY Critique of the Quality Pioneers IET 603 – Quality Assurance Science and Technology Travis Fisher 1/20/2013 If Total Quality were the branches of a tree then Continuous Improvement would be its roots. Being so, TQM is not superior to its own origin and therefore seeks the same results as its core, which is to continuously improve upon all processes and systems in the industrial world. Total Quality Management has been continuously improved upon for many years by many great minds, some of which will be discussed in the following article. Walter A. Shewhart is considered to be the grandfather of total quality management because he developed its original notions while working for the Bell Telephone company. Shewhart believed that lack of information greatly hampered the efforts of control and management processes in a production environment. In order to aid a manager in making scientific, efficient, economical decisions, he developed Statistical Process Control methods. Many of the modern ideas regarding quality owe their inspiration to Dr. Shewhart. He also developed the Shewhart Cycle Learning and Improvement cycle, combining both creative management thinking with statistical analysis. This cycle contains four continuous steps: Plan, Do, Study and Act which will lead to total quality improvement. The cycle draws its structure from the notion that constant evaluation of management practices as well as the willingness of management to adopt and disregard unsupported ideas are keys to the evolution of a successful enterprise (SkyMark, 2013). W. Edward Deming, who was actually taught by Walter Shewhart the importance of adapting management processes to create profitable situations for both businesses and consumers, is also considered a total quality pioneer. W Edwards Deming was an American statistician who was credited with the rise of Japan as a manufacturing nation, and with the invention of Total Quality Management (TQM). In 1982 Deming published the book "Out of the crisis" containing 14 points which he believed that if applied to US manufacturing industry would save the US from industrial doom at the hands of the Japanese (Demings 14 Points, 2013). Dr. Deming is well-known for these 14 points that create a more efficient workplace with higher profits, and increased productivity may grow. The points are as follows: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Create and communicate to all employees a statement of the aims and purposes of the company. Adapt to the new philosophy of the day; industries and economics are always changing. Build quality into a product throughout production. End the practice of awarding business on the basis of price tag alone; instead, try a longterm relationship based on established loyalty and trust. Work to constantly improve quality and productivity. Institute on-the-job training. Teach and institute leadership to improve all job functions. Drive out fear; create trust. Strive to reduce intradepartmental conflicts. Eliminate exhortations for the work force; instead, focus on the system and morale. (a) Eliminate work standard quotas for production. Substitute leadership methods for improvement. (b) Eliminate MBO. Avoid numerical goals. Alternatively, learn the capabilities of processes, and how to improve them. Remove barriers that rob people of pride of workmanship Educate with self-improvement programs. Include everyone in the company to accomplish the transformation. (MindTools, 2013) Joseph M. Juran made many contributions to the field of quality management in his 70+ active working years. His book, the “Quality Control Handbook”, is a classic reference for quality engineers. He revolutionized the Japanese philosophy on quality management and in no small way worked to help shape their economy into the industrial leader it is today. Dr. Juran was the first to incorporate the human aspect of quality management which is referred to as Total Quality Management. The process of developing ideas was a gradual one for Dr. Juran. Top management involvement, the Pareto principle, the need for widespread training in quality, the definition of quality as fitness for use, the project-by-project approach to quality improvement--these are the ideas for which Juran is best known, and all emerged gradually (SkyMark, 2013). The following table outlines the major points of Dr. Juran's quality management ideas: Quality Trilogy: Quality Planning Identify who are the customers. Determine the needs of those customers. Translate those needs into our language. Develop a product that can respond to those needs. Optimise the product features so as to meet our needs and customer needs. Quality Develop a process which is able to produce the product. Improvement Optimise the process. Quality Control Prove that the process can produce the product under operating conditions with minimal inspection. Transfer the process to Operations. The name Armand V. Feigenbaum and the term "total quality control" are virtually synonymous. In 1986, when the ASQ board of directors elected Feigenbaum an Honorary member, it acknowledged a career of more than 35 years in the quality field. During that career, the precepts of total quality control were carefully laid out and tirelessly promulgated in the United States and around the world. Feigenbaum's ideas are contained in his now famous book Total Quality Control, first published in 1951 under the title Quality Control: Principles, Practice, and Administration, and based on his earlier articles and program installations in the field. The book has been translated into more than a score of languages, including Japanese, Chinese, French, and Spanish. Feigenbaum is recognized as an innovator in the area of quality cost management. His was the first text to characterize quality costs as the costs of prevention, appraisal, and internal and external failure. Feigenbaum's diverse achievements and many awards testify to his profound influence on management strategy in the competition for world markets, and to the timeless good sense of total quality control (ASQ, 2013). Genichi Taguchi was an engineer and statistician. Born on the first day of 1924, Genichi Taguchi studied textile engineering at Kiryu Technical College. After WWII he worked for the Japanese Ministry of Public Health and Welfare and conducted the nation's first study on health and nutrition. He also applied his quality improvement knowledge at Morinaga Pharmaceutical and even worked for a candy maker, Morinaga Sieka, to reduce the melting properties of caramel at room temperature. From the 1950s onwards, Taguchi developed a methodology for applying statistics to improve the quality of manufactured goods. Taguchi methods have been controversial among some conventional Western statisticians, but others have accepted many of the concepts introduced by him as valid extensions to the body of knowledge (SkyMark, 2013). Taguchi has made a very influential contribution to industrial statistics. Key elements of his quality philosophy include the following: 1. Taguchi loss function, used to measure financial loss to society resulting from poor quality; 2. The philosophy of off-line quality control, designing products and processes so that they are insensitive ("robust") to parameters outside the design engineer's control; and 3. Innovations in the statistical design of experiments, notably the use of an outer array for factors that are uncontrollable in real life, but are systematically varied in the experiment. George Box was a chemist trying to develop defenses against chemical weapons in wartime England, which required him to analyze data from experiments. He sought statistical advice, but none was available, so he taught himself from the available texts. Perhaps because he had to teach himself statistics, George Box became one of the leading communicators of statistical theory to the rest of us. His “Statistics for Experimenters”, co-authored with Stuart and William Hunter is one of the most highly recommended texts for the field of experimental statistics. Box also wrote “Time Series Analysis: Forecasting and Control”, which is a practical, readable guide to dealing with time series data (SkyMark, 2013). These are just a few of the major contributors to the Total Quality that we know of today. Each in their own way have developed and innovated ways for companies to run more efficiently and productively. Bibliography ASQ. (2013). Retrieved from http://asq.org/about-asq/who-we-are/bio_feigen.html Demings 14 Points. (2013). Retrieved from http://www.hci.com.au/hcisite2/articles/deming.htm MindTools. (2013). Retrieved from Demings 14 Point Philosophy: http://www.mindtools.com/pages/article/newSTR_75.htm SkyMark. (2013). Retrieved from Total Quality Management: http://www.skymark.com/resources/leaders/shewart.asp