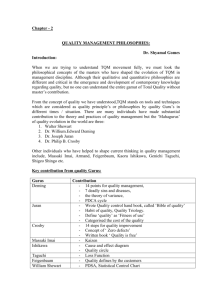

QUALITY TIME LINE Quality History: Frederick Taylor's Scientific Mgt

advertisement

9/2/2014 Quality History: Frederick Taylor’s Scientific Mgt. Lean Six Sigma (Late 1800’s – Early 1900’s) Work as a system – Work standards Æ Intent drive down labor costs LOWERED QUALITY BY: Component divisions p (Division of Labor) 2000-Present US u use of Deming & Taguchi 1980 Deming Quality Management 1950 Shewhaart - SPC Dodg ge & Romig - AQL 1930 1925 Birtth Of “Taylorism” 1875 Pre-Industriall Revolution QUALITY TIME LINE QUALITY FADS FUTURE Work standards (speed over quality, incentive pay) Frederick Taylor (www.pharmacorner.com) Acceptable Quality Levels Quality History: Dr. Walter Shewhart Dr. WALTER SHEWHART’S QUALITY (1920’s Bell Labs) Invented the control chart Invented PDCA Cycle Dr. Shewhart (www.pharmacorner.com) Quality History: WORK STANDARDS (Frank & Lillian Gilbreth) Process control Economic, routine operation of the process Importance of only chance variation (consistency) Used statistics to identify and remedy root causes of variation Developed control chart to monitor processes Reduce process variation Æ Improve the process Identified: • Controlled variation (common causes), Predictable • Uncontrolled variation (special or assignable causes) Quality History: WORK STANDARDS (Frank & Lillian Gilbreth) (Early 1900’s) IMPROVED QUALITY BY: Taylor followers ‐ time studies (e.g. brick laying) Æ Work Simplification Filming Processes (Micro‐motion time studies) Human Factors/Safety LOWERED QUALITY BY: Frank & Lillian Gilbreth Work Standards = cap productivity, stifled CI) (gilbrethnetwork.tripod.com) (www.telelavoro.rassegna.it) 1 9/2/2014 Quality History: H. DODGE & H. ROMIG’S AQL (1930’s‐1940’s Bell Labs) ACCEPTANCE SAMPLING LOWERED QUALITY BY: Focused on product = not improvement of process Reject parts by AQL Contained bad parts = not prevention Product control Keep defective product from customer’s hand “Acceptance Sampling” to pass judgement on large quantities QUALITY HISTORY: Juran’s Quality Mgt. (1950’s) Dr. Joseph M. Juran – quality is fitness for use Wrote the “Quality Control Handbook” Founder of ASQC Concept of “acceptable level” of defects = Accepted scrap as part of business Æ Encouraged belief in economic trade‐off between continual improvement and the cost to do so Æ (if uneconomical) Æ doesn’t allow quality and productivity to improve together Quality History: Dr. Joseph M. Juran Quality approach à Create awareness of need to improve à Make quality improvement integral part of each job à Provide training in quality methods à Establish team problem solving à Recognize results Three Managerial Processes à Quality Planning à Quality Control à Quality improvement Dr. Juran (qualitythai.net) Quality History: FEIGENBAUM’S FEIGENBAUM’S QUALITY (1960’s) Quality History: Dr. Armand Feigenbaum Originator of Total Quality Armand Feigenbaum ‐ A customer Armand Feigenbaum determination which is based on the customer’s actual experience with the product or service, measured against his or her requirements ‐ stated or unstated, conscious or merely sensed technically conscious or merely sensed, technically operational or entirely subjective ‐ and always representing a moving target in a competitive market Quality is a management mindset Quality is a fundamental element of a business strategy Determining cost of poor quality Quality is what the customer says it is Dr. Feigenbaum (www.baldrige21.com) 2 9/2/2014 TQM Total Quality Management ‐ places emphasis on continuous process/system improvement as a means of achieving customer satisfaction to ensure long‐term company success ‐ Uses expertise of all employees in conjunction with SPC Quality History: Crosby’s QUALITY (1970’s) Philip Crosby – à Quality is conformance to requirements à Zero defects. Make it right the first time à Prevention of defects – find root cause & correct à Cost of quality – cost to provide customer product or service that meets expectations à Quality should be led by management Quality History: GENICHI TAGUCHI Quality History: Loss Function (1980’s) Japanese engineer Use of designed experiments (DOE) à Select process/product to be studied à Identify important variables à Reduce variability on these variables through redesign, Reduce variability on these variables through redesign process improvement and tolerancing à Open up tolerances on unimportant variables Genichi Taguchi ‐ The “loss imparted to society during product use as a result of functional variation and harmful effects” as measured by the customer during field use. Not just a shipping criterion, but a design and manufacturing Criterion manufacturing Criterion. Use inexpensive variables to improve process Genichi Taguchi (www.csupomona.edu) Loss function concept – costs grow exponentially the farther from the target a process varies Quality History: GENICHI TAGUCHI Intent: à Improve quality & consistency à Lower cost à Identify key product & process factors before production Taguchi: Signal to Noise Ratio More Output = More Noise Output Signal to Noise Ratio Quality is a design issue, not just production Robust parameter design Value Value Waste Waste Design of Experiments (DOE) 3 9/2/2014 Taguchi: Signal to Noise Ratio GENICHI TAGUCHI: Design of Experiments Want More Output Æ Decrease Your Noise Ratio DOE: Select process/product to be studied Identify all variables Identify significant variables that affect output Reduce variability on these variables through redesign, process improvement and tolerancing Open up tolerances on unimportant variables Use inexpensive variables to improve process V l Value Waste TAGUCHI’S QUALITY: LOSS FUNCTION TRADITIONAL VS LOSS FUNCTION Quality is “loss imparted to society during product use as a result of functional variation and harmful effects.” Harmful effects = unrelated to function Functional Variation = deviation from intended design LOSS FUNCTION VS TOLERANCES TAGUCHI’S LOSS FUNCTION CONCEPT $$ JAPAN UPPER SPEC LOWER SPEC UPPER SPEC Co ost LOWER SPEC US $ A B T Quality Characteristic A B T Quality Characteristic 4 9/2/2014 TAGUCHI’S LOSS FUNCTION Quality History: Deming (1950’s –– technically 1930’s (1950’s technically 1930’s‐‐early 1990’s) LOWER SPEC W. Edwards Deming ‐ Deming ‐ A product or a service possess Quality if it helps someone live better materially and spiritually and enjoys a large and sustainable market. (Balaji Balaji S. S. Reddie Reddie, , Founder, The Deming Forum, India) UPPER SPEC Coost The key to low cost is to be on target with the least variability $$$ $$ $ T Quality Characteristic Quality History: Dr. W. Edwards Deming Turned Japan’s quality around Deadly diseases Obstacles 14 points (www.baldrige21.com) Deming is known to be one of the most influential persons on Quality as we know it 5