Reading guide Variation through the ages

advertisement

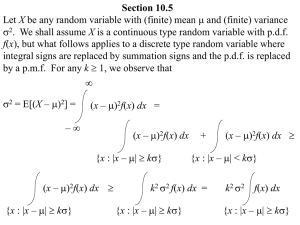

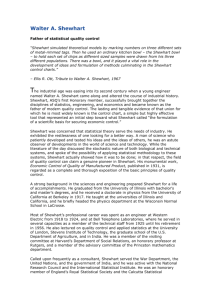

L. P. Provost and C. L. Norman, Variation through the Ages (Quality Progress, December 1990) Reading guide Some parts of this paper will be discussed in more detail in upcoming lectures. In particular, the issues raised on pp. 42-43 will be explained thoroughly during the lectures. However, in order to better understand the lectures, it is recommended to study these pages briefly and answer the questions presented below. Questions 1. 2. 3. 4. 5. Describe the three methods of managing variation mentioned in the text. Describe the different test methods mentioned in this text. Why was variation not a critical issue in the period before 1700? When and why did variation become a critical issue? What was the reason that standards for inspection were formulated at the end of the 19th century? 6. Explain the go/ no-go principle. 7. What is the goal of setting tolerances and specifications? 8. Explain the term interchangeability and give an example of a 'modern' product with interchangeable components. 9. Explain the relation between interchangeable components and variation. 10. What is the goal of a Shewhart control chart? 11. In what sense does Shewhart’s approach differ from the approach based on setting specifications? 12. What were the reasons for Shewhart to put control limits at a distance of 3 standard deviations of the target value? 13. Look up the section on Chebyshev’s inequality in your probability and statistics text book. What are the probabilities of being outside one of the control limits if the control limits are at 2 or 3.5 , respectively? For which type of distribution can we use Chebyshev’s inequality to obtain probabilities for being outside the upper control limit? 14. In what sense was the Shewhart approach based on control charts better for workers than the Taylor approach based on specifications and inspection. 15. Explain the idea behind Taguchi's quadratic loss function. 16. Explain what is meant by tolerance stack-up (see p. 44, 1st paragraph below figure 3). 17. If 2 components each have a deviation of target weight which is normally distributed with mean 0 and variance 2, what is the probability that the deviation of the total weight of the 2 components falls outside control limits set at 3?