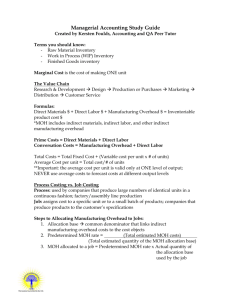

Managerial Accounting Chapter 8

advertisement

1 Chapter 2 Product Costing Prepared by Diane Tanner University of North Florida Assigning Costs to Cost Objects • Three methods – Actual costing – Normal costing – Standard costing • Differ in how product costs are assigned to products or services Actual Costing Normal Costing Standard Costing Direct Materials Actual Actual Budgeted* Direct Labor Actual Actual Budgeted* Manufacturing Overhead Actual Budgeted Budgeted* 2 Normal Vs. Actual Costing Normal costing Used effectively when there are multiple products Allocates manufacturing overhead to individual products based on a ‘predetermined’ rate calculation Estimated MOH Based on estimates Estimated Activity Actual costing Allocates manufacturing overhead to individual products based on an end of period rate calculation Actual MOH Based on actual amounts Actual Activity 3 How Costs Get Assigned to Products Direct materials and direct labor Traced to a product or service provided Because it is easy to determine which product/service to which the cost belongs By definition, direct costs are directly associated Manufacturing overhead Consists solely of indirect costs Indirect costs cannot be easily identified with one specific product or service Allocated to products and services 4 Production Departments Materials Storeroom Factory/Production Area Raw Materials Work in Process Costs in departments correlate to inventory accounts. Ready for Sale Finished Goods 5 Acquiring Raw Materials 1 The Purchasing Manager fills out an electronic purchase order to order materials from a supplier Materials Storeroom 2 When materials are received, the Materials Storeroom Clerk records and stocks the materials in the storeroom. Debit Raw Materials Credit Cash or Accounts Payable 3 The Materials Storeroom Clerk sends the receiving report to Accounting for payment. 6 Materials Requisition Factory/Production Area 1 The production supervisor fills out a materials requisition form. A materials requisition form authorizes the use of materials on a product or job 2 The materials storeroom clerk delivers the requested materials to the production area. DIRECT MATERIALS Debit Work in Process Credit Raw Materials INDIRECT MATERIALS Debit Manufacturing Overhead Credit Raw Materials 3 The processed form is sent to Accounting. 7 8 Direct Labor • Employees fill out time tickets which indicate the hours worked on each product • Time tickets = source documents • Direct labor cost = gross wages + fringe benefits Gross wages = [Hourly rate] × [Number of hours worked] Fringe benefits Normally included as part of the direct labor ‘rate’ Overtime premium (the extra ‘half’ time paid) If the result of production problems, treat as manufacturing overhead If the result of accepting a rush order, treat as direct labor Idle time Treat as overhead Incur direct labor costs Debit Work in Process Credit Cash or Wages Payable Manufacturing Overhead Includes indirect materials, indirect labor, and factory (production facility) related costs Incur factory-related costs Debit Manufacturing Overhead Credit Cash, Payables, Prepaids, etc. Requisition indirect materials to production Debit Manufacturing Overhead Credit Raw Materials Incur indirect labor costs Debit Manufacturing Overhead Credit Cash, Salaries payable, etc. 9 Accounting for Overhead in a Normal Costing System When actual overhead costs are incurred Debit to MOH expense account Apply (allocate) overhead to products Predetermined MOH rate(s) Traditional method - use a single rate Activity based costing – use multiple rates Multiply the rate(s) times the actual activity Debit WIP Credit MOH expense When is overhead applied? As the activity occurs 10 This chapter assumes a single rate 11 Assigning Overhead NORMAL COSTING • Overhead rate is determined at the beginning of the period using estimated amounts • MOH is ‘applied’ (allocated) to products – During production ACTUAL COSTING • Overhead rate is determined at the end of the period using actual amounts • MOH is ‘applied’ (allocated) to products – At the end of the period Selecting an Activity The denominator of the pre-determined overhead rate is ‘estimated activity’ Common estimated activities include Number of units to be produced Number of direct labor hours to be used Number of direct labor dollars to be incurred Number of machine hours to be used Based on management’s best guess of what causes costs to increase 12 Applying Overhead Based on Units McAlister Company provided the following amounts: Estimated MOH costs = $50,000 Actual MOH costs = $49,500 Estimated units to be produced = 4,000 Actual units produced = 4,100 The company allocates overhead based on units produced. Step 1: Determine the allocation rate (POHR) = $50,000/4,000 = $12.50/unit Step 2: Apply overhead: Applied = $12.50 x 4,100 = $51,250 MOH 49,500 51,250 1,750 overapplied 13 Applying Overhead Based on DL Hours McAlister Company provided the following amounts: Estimated MOH costs = $50,000 Actual MOH costs = $49,500 Estimated direct labor hours = 12,500 Actual direct labor hours = 12,400 The company allocates overhead based on DL hours. Step 1: Determine an allocation rate (POHR) = $50,000/12,500 = $4.00/DL hour Step 2: Apply overhead: Applied = $4.00 x 12,400 = $49,600 MOH 49,500 49,600 100 overapplied Applying Overhead Based on DL Cost McAlister Company provided the following amounts: Estimated MOH costs = $50,000 Actual MOH costs = $49,500 Estimated direct labor cost = $156,250 Actual direct labor cost = $153,600 The company allocates based on DL hours. Step 1: Determine an allocation rate (POHR) = $50,000/156,250 = $0.32 per DL$ Step 2: Apply overhead: Applied = $0.32 x $153,600 = $49,152 MOH 49,500 49,152 Underapplied 348 15 Why is Normal Costing Better than Actual Costing? • Overhead is applied during production – Enables managers to know product and job costs as production occurs, i.e., on a timely basis • Waiting until the end of the period when actual costs are known makes information untimely – Useful for making decisions such as pricing, product changes, etc. Overhead cannot be traced to products because it is impractical or impossible to identify these costs with a particular product. 16 17 Completing Products The cost of completed goods is transferred out of Work in Process Debit Finished Goods Credit Work in Process The cost transferred out is called Cost of Goods Manufactured 18 Selling Products Transfer the cost of products sold out of Finished Goods Debit Cost of Goods Sold Credit Finished Goods Recognize the sale Debit Cash or AR Credit Sales Revenue The End 19