By DAN PARRY - manufacturing engineer

with Belvac Production Machinery, Inc.

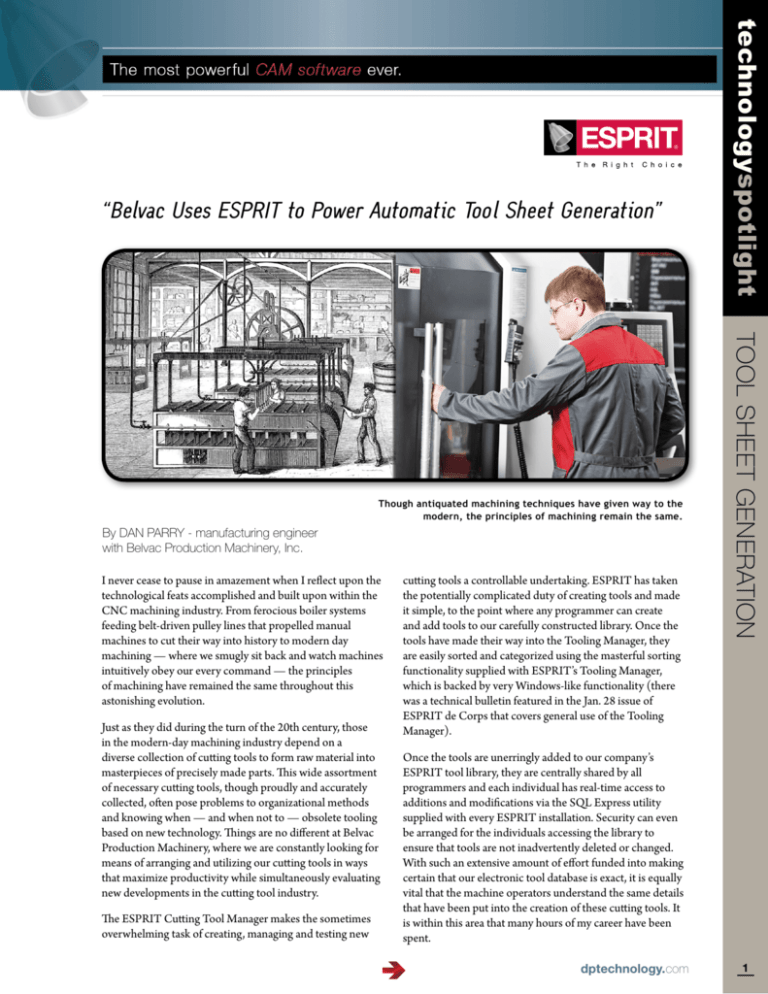

I never cease to pause in amazement when I reflect upon the

technological feats accomplished and built upon within the

CNC machining industry. From ferocious boiler systems

feeding belt-driven pulley lines that propelled manual

machines to cut their way into history to modern day

machining — where we smugly sit back and watch machines

intuitively obey our every command — the principles

of machining have remained the same throughout this

astonishing evolution.

Just as they did during the turn of the 20th century, those

in the modern-day machining industry depend on a

diverse collection of cutting tools to form raw material into

masterpieces of precisely made parts. This wide assortment

of necessary cutting tools, though proudly and accurately

collected, often pose problems to organizational methods

and knowing when — and when not to — obsolete tooling

based on new technology. Things are no different at Belvac

Production Machinery, where we are constantly looking for

means of arranging and utilizing our cutting tools in ways

that maximize productivity while simultaneously evaluating

new developments in the cutting tool industry.

The ESPRIT Cutting Tool Manager makes the sometimes

overwhelming task of creating, managing and testing new

cutting tools a controllable undertaking. ESPRIT has taken

the potentially complicated duty of creating tools and made

it simple, to the point where any programmer can create

and add tools to our carefully constructed library. Once the

tools have made their way into the Tooling Manager, they

are easily sorted and categorized using the masterful sorting

functionality supplied with ESPRIT’s Tooling Manager,

which is backed by very Windows-like functionality (there

was a technical bulletin featured in the Jan. 28 issue of

ESPRIT de Corps that covers general use of the Tooling

Manager).

Tool Sheet Generation

Though antiquated machining techniques have given way to the

modern, the principles of machining remain the same.

technologyspotlight

“Belvac Uses ESPRIT to Power Automatic Tool Sheet Generation”

Once the tools are unerringly added to our company’s

ESPRIT tool library, they are centrally shared by all

programmers and each individual has real-time access to

additions and modifications via the SQL Express utility

supplied with every ESPRIT installation. Security can even

be arranged for the individuals accessing the library to

ensure that tools are not inadvertently deleted or changed.

With such an extensive amount of effort funded into making

certain that our electronic tool database is exact, it is equally

vital that the machine operators understand the same details

that have been put into the creation of these cutting tools. It

is within this area that many hours of my career have been

spent.

dptechnology.com

1

Without going into

too much detail

about why and how

the snapshot above

is created by the post

processor, we can take

a quick look to get a

general understanding

of what is happening

behind the scenes. This way someone can easily change the output to conform to their needs.

The first part of the code (i.e. program number, part number, set-up instructions, etc.) is controlled by the EX_STARTCODE

example in the post processor. A closer look proves to be somewhat self-explanatory when considering the terminology used

in EX_ STARTCODE.

Tool Sheet Generation

Being easy to use, centrally located and robust, the ESPRIT Tooling Manager became our primary and only electronic tool

library. We can now use the post processor to extract the parameters from within the ESPRIT tool and systematically arrange

it at the top of our NC code along with the rest of the standard information for a specific program that the machine operators

are accustomed to

seeing. Things like

Sample Tool Sheet

part number, program

number and set-up

instructions were

already located at

the top of each NC

code file, so it made

sense to put our

automatically-created

tool sheet here. The

red box encompasses

Belvac’s tool sheet.

technologyspotlight

I assumed there may be other ESPRIT users faced with this problem and therefore decided that I would use this article

to discuss the one method that I have found most useful. After trying and falling short with many different means of

communicating the details of a cutting tool library to the machine operators, I have finally found one that consolidates

multiple file types and eliminates the need for maintaining redundant information. Rather than maintaining multiple libraries

and/or databases of tooling information, we at Belvac decided to focus our attention where it had the biggest impact: the

ESPRIT Tooling Manager.

Next is a string of text representing column headings for the individual parameters that will be pulled from the ESPRIT tool

and placed in the corresponding columns.

Each column heading entails a two-letter acronym that corresponds to a field from within the ESPRIT tool page that it

symbolizes (e.g. TN is for Tool Number, TD is for Tool Diameter, etc.). Since there are quite a few acronyms, it may take a

dptechnology.com

2

technologyspotlight

Sample Generic tool setup

to sequentially pull the parameters from the ESPRIT tool

and populate the individual columns in the tool set-up sheet

using that data. The Tool Comment is then placed directly

underneath the parameters of the tool and can include any

additional specifics about the tool.

The next part of the post processor is where the real magic

happens. We use the EX_TOOLDEFINITION example

The CL File Number is used to call the value that is

associated with that particular field. To find out which CL

dptechnology.com

Tool Sheet Generation

while for the machine operators to remember what they

all stand for. To help with this scenario, we have provided

the machine operators with a picture of a generic tool that

depicts the dimensions on the tool that each column heading

signifies.

3

In conclusion, ESPRIT’s ability to automatically output a

tool sheet based on the tools used in a program provides

many benefits to our company. Potential errors are

eliminated by focusing solely on the tool information entered

within the CAM system rather than duplicating this data

inside of a tool management system or some other means of

storing electronic tools. We also estimate a conservative 3%

reduction in the time it takes to create a single program by

not having to create a separate tool sheet to deploy tool setup information to the machine operators. Not to mention the

time saved by not having to view, maintain and store multiple

file types since the tool sheet is directly within the NC code.

Tool Sheet Generation

In the seldom, but nevertheless preset, case where we need

to create a tool that uses a holder that cannot be defined

only by using the parameters supplied in a tool, we revert to

the custom shank functionality to properly define the tool.

The picture below shows an example of how it is possible to

use the custom shank option to define a tool holder that is

tapered.

While the ability to describe a custom tool holder using the

shank category is undoubtedly handy, it tends to throw a

wrench into allowing the post processor to handle tool-sheet

creation by extracting the parameters from the tools in the

program. To handle this situation, we have added an “if ”

statement within the EX_TOOLDEFINITION example to

allow the user to use Custom Settings to declare the values

that may not be output correctly if allowed to be driven by

the fields that would normally explain the dimensions for

certain factors of the tool. The “if ” statement, as explained

below, allows the user to set the Custom Setting 1 field to

a value of 1, then the Tool Length, Extension Diameter,

Bottom Length and Holder Diameter will all be defined

using Custom Setting fields.

technologyspotlight

File Number a particular field has, simply right click on a field

and select Edit Properties. For example, notice in the picture

below that the Tool Diameter field has CL File Number 103.

I suppose the marvelous capabilities and ever-changing

technology of cuttings tools is in some ways a double-edged

sword. It’s a constant chore to organize, store and utilize the

right cutting tool for the job, but nevertheless we wouldn’t

be able to accomplish the amazing achievements that take

place daily within the machining industry without them. “It’s

amazing what can be done with the right tools.” This was one

of my father’s favorite sayings when I was growing up. I’m

proudly passing the importance of that statement along to

my own son while trying to instill in him my appreciation for

the fantastic world of tools and manufacturing that surrounds

us.

Custom shank end mill holder

While it is usually a challenge to maintain our everexpanding tool libraries, DP Technology has ensured that

ESPRIT makes this duty one less thing to worry about. With

the undertaking of supplying our machine operators with a

detailed tool sheet out of the way, Belvac programmers have

dptechnology.com

4

Tool Sheet Generation

Parry’s son, Daniel, explores the fantastic

world of tools and manufacturing.

DP Technology Corp.

1150 Avenida Acaso

Camarillo, CA 93012 USA

technologyspotlight

that much more time to focus on automating other parts

of our processes. One win at a time, we will continue to

use ESPRIT, “The Most Powerful CAM Software Ever,”

to quickly and efficiently produce NC programs. g

Phone: 1 800 627-8479

Outside the US: + 1 805 388-6000

Email: esprit@dptechnology.com

ESPRIT is a registered trademark of DP Technology Corp.

©2011 DP Technology Corp. All rights reserved.

dptechnology.com

5