customerspotlight

Delivering Quality on Demand

Cullip Industries

One of the main features of ESPRIT

inspired

Cullip’sby

purchase

Parts that

machined

in ESPRIT

Central was

Utahthe

Tool.

ESPRIT KnowledgeBase™, a database for storing tools, speeds and feeds.

By Stacey Wiebe

Cullip Industries Delivers Rapid-Fire

Service with ESPRIT CAM

that doesn’t mean that Brinks didn’t earn his stripes. And

though the nature of the job has changed since the company

was founded in 1959, its goals remain the same.

CJ Brinks counts his blessings as he stares from his Indiana

office and into a snowy afternoon framed by the coming

twilight.

“Our mission statement — our filter for everything that we

do — is to deliver quality on demand,” Brinks says, taking a

breather to talk about life at Cullip before he heads home.

It’s near quittin’ time on a Friday and Brinks, whose shirt

sports a name tag that bears the words “plant manager,”

answers a few last-minute questions as the staff of Cullip

Industries streams through the door and into the waiting

weekend.

“That’s what ESPRIT allows us to do: deliver quality on

demand.”

Times have changed in the seven years since the 27-year-old

father of two started his career cleaning the machines on

Cullips’ shop floor.

Sure, it’s a family business and, sure, it doesn’t hurt that

business owner, John Cullip, is Brinks’ father-in-law — but

By ESPRIT®, Brinks means the plant’s computer-aidedmanufacturing (CAM) software by DP Technology Corp.

The software has been part of Cullip’s lineup for about

12 years, since John Cullip switched to ESPRIT from the

company’s former CAM software.

Incidentally, the company made the switch to CNC machine

tools in 1982, when Cullip urged his father, the business’s

original owner, to take the leap.

dptechnology.com

1

customerspotlight

In the intervening years, Cullip has

become less a tool-and-die house and

more a job shop.

“ESPRIT had exactly what we needed,”

says Brinks, who heads up all mill

programming at the plant, by way of

explanation. “What we needed was

software that could help us program

parts quickly.”

CJ Brinks, Cullip’s plant manager.

Though the use of ESPRIT is among

the blessings Brinks is counting, he

doesn’t stop there.

For starters, there’s his “wonderful, fantastic wife, Amy,” his

4-year-old girl, his 2-year-old boy and a new baby girl arriving

in March.

There’s also the fact that, despite a questionable economy,

business has been better than ever. The company has even

hired additional staff to shoulder the load.

Though the business began its 50-plus year run as a tool

and die shop, Cullip is now primarily a job shop that serves

four main customers and derives roughly 50 percent of its

business from the aerospace industry.

that Cullip dropped more than half of its previous 10 or so

customers.

By decreasing demands on its time, the company made itself

ready and able to respond to changes and deliver rapid-fire

service with a personal touch.

With ESPRIT and a range of machine tools — including an

assortment of vertical and horizontal mills, a trio of lathes,

one wire EDM machine and one Citizen L-32 Swiss-style

lathe, the company is better equipped than ever to respond to

change at the click of a mouse.

Cullip Industries

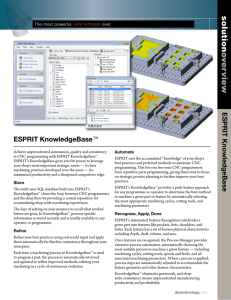

One of the main features of ESPRIT

that inspired Cullip’s purchase was the

ESPRIT KnowledgeBase™, a database

for storing tools, speeds and feeds.

“We saw this feature as a potential time

saver, and it has been,” Brinks says.

“Our mission statement — our filter for everything that we do — is

to deliver quality on demand. That’s what ESPRIT allows us to do:

deliver quality on demand.” -- CJ Brinks, Cullip Industries

Twenty percent of that aerospace business is attributed to a

single customer that specializes in cooling systems.

Though it also provides parts for a maker of professionalgrade paint sprayers and two other mainstays, Cullip seeks

to diversify business by adding a couple more customers and

continuing to deliver the service that sets it apart.

“We were getting pulled in so many directions, so we decided

a few years ago to decrease the number of customers so we

could really serve the ones we have,” says Brinks, who adds

“It’s been a good situation for us,” Brinks says. “We found

that if we take care of our customers, they more than take

care of us.”

Though materials commonly used by the company — such

as various stainless steels, cold-rolled steel and aluminum —

are not of the challenging variety, the parts it’s being asked to

make are of the increasingly complicated sort.

“Our customers are giving us some complex things to do,”

Brinks says. “With the assistance of ESPRIT, we have proven

dptechnology.com

2

customerspotlight

we can handle more complex parts

with the equipment we currently own.

Our customers have seen this and

are asking us to quote these complex

parts.”

“Among the tougher dimensions on the

part is a ground radius that is held to

.0005-inch in both size and position,”

Brinks says. “The customer requires the

part to be both flat and perpendicular

within .001 along the entire length of the part.”

This part was completely programmed in ESPRIT and, as

Brinks explains, it “had a new shape” after each operation.

“We used ESPRIT to generate the solid shape at the

beginning of the operation to see how to hold the part,

how to avoid colliding with pre-existing walls, and how the

part will look when the operation is complete,” Brinks says.

“Simply put, ESPRIT saved us several headaches before

setting up the part in the machine. The limit to the ability of

ESPRIT has rested in me as the user, not in the software.”

“What I like about ESPRIT is that it’s straightforward,

simple, and user-friendly,” adds Brinks, who had no

experience with CAD or CAM software prior to his

experience with ESPRIT and learned the software using selfguided tutorials.

DP Technology Corp.

1150 Avenida Acaso

Camarillo, CA 93012 USA

The shop floor at Cullip Industries.

Though the self-starter in Brinks had no problem picking up

the intricacies of the user-friendly software, he’s thankful for

the rapid response to that DP Technology aims to deliver to

its own customers — not unlike Cullip Industries.

“Though many different types of CAM software will do what

you need them to do, it’s the service that we receive that sets

ESPRIT apart. We have yet to use any software of any sort

in the shop that has such a good response,” he continues.

“If we have a question, DP Technology has an answer in 30

minutes or less. All it takes is a short phone call. We use the

software every day and, if something comes up that we can’t

fix or change, we can’t afford to wait days or even hours for an

answer. This is where ESPRIT excels.” g

Cullip Industries

Among those parts is a lock system

for a printing press that begins as a

35-pound piece of 416 round stainless

stock with a two-and-a-half-inch

diameter. When the part — which

requires a tolerance of plus or minus

.0005 on several dimensions — comes

off the machine, the 28-inch-long part

sports holes and odd angles and has

been pared down to 11 pounds.

ON THE WEB:

www.cullipindustries.com

Phone: 1 800 627-8479

Outside the US: + 1 805 388-6000

Email: esprit@dptechnology.com

ESPRIT is a registered trademark of DP Technology Corp.

©2011 DP Technology Corp. All rights reserved.

dptechnology.com

3