Jominey End Quench Lab 4

advertisement

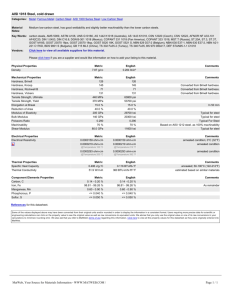

JOMINEY END QUENCH LAB AILEEN JOHNSRUD 4/7/2015 Gradient Cooling Jominey testing further demonstrates the effects of annealing & quenching, by rapidly cooling and simultaneously slowly cooling opposite ends of a heat treated rod of 1018 steel. Hardenability is an alloys ability to be hardened to a particular depth. Jominey End Quench Lab Jominey End Quench Lab GRADIENT COOLING INSTRODUCTION|ONE The Jominy end quench test is the most commonly used method for determining the hardenability of steel. Hardenability is the relative capacity of steel to be hardened by transformation to martensite. In this test, a standard specimen (octagonal cross-section bar stock) is heated to the austenite range and quenched by impinging a stream of cold water on one end of the specimen while the specimen is held in a vertical orientation. This procedure results in cooling rates ranging from very rapid at the end impinged by the water to very slow at the opposite end. With the variation in cooling rate along the length, a single specimen will be composed of material ranging from hard martensite to soft pearlite. PROCEDURE|TWO A sample specimen of 1018 steel measuring 1” in diameter by 4” length is used 1) Five Rockwell B hardness tests are performed on this specimen. This is the control 2) 1018 steel specimen is heat treated for 1 hour in a 1700o oven 3) 1018 steel specimen is removed and swiftly mounted vertically into the Jominey, where it is cooled for 15 minutes with a controlled spray of cool water directed at one end of the hot steel rod. Page 1 Jominey End Quench Lab 4) After Jominey testing is complete the specimen is descaled using a steel brush to better provide accurate and unhindered Rockwell test results. 5) Rockwell B test is re-preformed on the heat treated and gradient cooled 1018 steel. Hardness is measured at 1/8” increments along the length, beginning with the quenched end and ending with readings from the slowly cooled end. RESULTS|THREE Measurements of the control hardness test done prior to heat treatment and Jominey test are; 86, 86, 86.5, 86, 86.5 This is the control The cooling rate decreases as one moves further from the quenched end, you can measure the effects of a wide range of cooling rates from vary rapid at the quenched end to air cooled at the far end. Below are Rockwell B results. Page 2 Jominey End Quench Lab DISCUSSION & CONCLUSION|FOUR WE ARE ABLE TO VIEW THE CHANGES IN THE MICROSTRUCTURE OF THE 1018 STEEL AS RAPID COOLING INCREASES IN HARDNESS AND DECREASES AS SLOWER COOLING OCCURS. HARDENABILITY INCREASE IS TYPICAL IN STEELS ALLOYED WITH CARBON, BORON, CHROMIUM , MANGANESE, MOLYBELDUM , SILICON, & NICKEL . JOMINEY TESTING PROVIDES US WITH THE EFFECT ON HARDNESS, NOT HEAT TRANSFER . THE HARDENABILITY OF STEEL DIFFERS FROM HARDNESS. HARDENABILITY IS THE ABILITY OF THE STEEL TO PARTIALLY OR TO COMPLETELY TRANSFORM FROM AUSTENITE TO SOME FRACTION OF MARTENSITE AT A GIVEN DEPTH BELOW THE SURFACE, WHEN COOLED UNDER A GIVEN CONDITION FROM HIGH TEMPERATURE . THE QUENCH (RAPID COOLING) AND TEMPER IMPROVES THE MARTENSITE CHARACTER OF BOTH STRENGTH AND TOUGHNESS IN STEEL. Page 3