Tutorial for Lecture 12: The heat-treatment of plain

advertisement

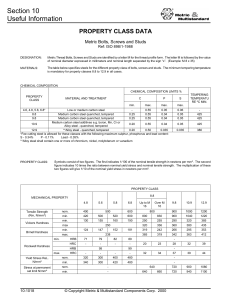

Tutorial for Lecture 12: The heat-treatment of plain-carbon steels QUESTIONS Higgins Ch12 1. 2. 3. 4. 5. 6. Define all the glossary terms. Why are isothermal heat treatments of carbon steel limited to thin sections? Why are there a range of different quenching fluids? When a carbon steel is quenched, which grain structure causes hardness? If a quenched steel is too hard, what process can be used to toughen it? On the TTT curve for a particular carbon steel, what advantage is there in avoiding the ‘nose’ of the curve – as isothermal heat treatments do? 7. List iron grain structures that are super-saturated with carbon. 8. Describe the difference between heat treatment of hypo and hyper-eutectoid steels. Why is hyper-eutectoid more complicated? 9. Describe the Jominy test. What does it measure? 10. Describe how Critical Cooling rate can be modified by %C or alloys elements. 11. An injection mould tool is made from thick steel sections that must be hard. Explain why you would choose a carbon or alloy steel. Give an example of a suitable alloy from this chart. 12. Summarise the advantages and disadvantages of the three carburising methods shown in the video: Pack carburising , cyanide and plasma. Glossary Martensite Bainite Super saturated solution Critical cooling rate Tempering Martempering Austempering Ruling section Jominy Test © TAFE NSW Higher Education 2012 Version: X | Day-Month-Year 1