UNIVERSIDAD AUTÓNOMA DE NUEVO LEÓN

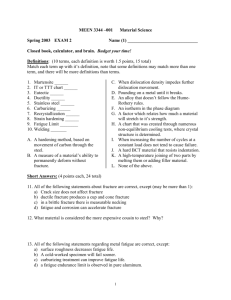

advertisement