Sinter Hardening Response Of A Cr-Si-Ni-Mo Containing Steel

advertisement

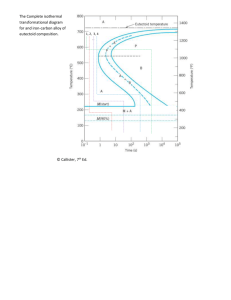

Sinter Hardening Response Of A Cr-Si-Ni-Mo Containing Steel Bruce Lindsley and W. Brian James Hoeganaes Corporation, Cinnaminson, NJ 08077, USA Abstract A number of sinter-hardenable materials have been developed over the past several years. Notable among these are Ancorsteel® 737 SH (prealloyed Mo, Mn, Ni steel), Ancorsteel 4600V (prealloyed Mo, Ni Steel) and hybrid alloys containing prealloyed molybdenum with copper and admixed nickel. All these materials use copper to enhance hardenability. Ancorsteel 4300 (Cr-Si-Ni-Mo containing steel) exhibits excellent hardenability without the addition of copper, with as-sintered hardnesses greater than 20 HRC utilizing cooling rates typically found in production sintering furnaces. A quantitative study to assess the hardenability of this alloy system has been undertaken and a comparison will be made with more traditional Mo-Ni-Cu alloys. Continuous sinter cooling transformation curves will be presented along with apparent hardnesses and metallographic analysis of various phase fractions. Introduction Sinter-hardenable P/M steel compositions allow the P/M industry to eliminate the expense of austenitizing and oil quenching parts. These compositions are typically prealloyed Mo-Ni or Mo based to which Cu is admixed. Ancorsteel 4300 utilizes chromium and silicon to enhance the hardenability beyond Mo-Ni steels and does not require the addition of copper. Copper additions have become a concern with respect to scrap recycling. The use of chromium in wrought steels is a result of both its effectiveness as an alloying element and its relatively low cost. Until recently, Cr had not been used in P/M steels due to oxidation concerns. Silicon containing steels (Ancorloy® MD series) had been developed earlier that utilized the strengthening contribution of silicon, but required high temperature (1260 °C) sintering (1,2). Ancorsteel 4300 builds on the advantages of the silicon containing steels with the addition of Cr, but does not require high temperature sintering. The hardenability of this steel is examined within the range of cooling rates typically found in production sintering furnaces and compared with P/M steels that contain more conventional alloying elements. Experimental Procedure The continuous sinter cooling transformation (CSCT) method is similar to the traditional continuous cooling transformation (CCT) method for determining hardenability utilizing high ® Ancorsteel and Ancorloy are registered trademarks of Hoeganaes Corporation temperature dilatometry. The method used in this study is similar to that described by Semel (3,4) with some minor modifications. A brief overview of the procedure follows. The composition of Ancorsteel 4300 is given in Table I along with alloy FLC-4608. Samples, with a length and width of 11.6 mm and thicknesses of 3.8, 6.4 and 10 mm, were pressed to a green density of 7.1 g/cm3 and sintered in a ceramic belt furnace at 1120 °C (2050 °F) in a 90 vol% nitrogen – 10 vol% hydrogen atmosphere. An additional set of 4300 samples was sintered at 1260 °C in the same furnace and atmosphere. The samples were then tempered at 650 °C to soften the alloys and allow a hole to be drilled for a thermocouple in the specimens. Individual samples were then placed in a high temperature dilatometer and heated to 1120 °C and held for 10 minutes. The samples were cooled to 865 °C and held for 5 minutes to stabilize the temperature prior to accelerated cooling. The samples were then cooled at different rates by changes in sample thickness, furnace position and gas flow rate. The gas used in the dilatometer was 90 vol% helium – 10 vol% hydrogen at a flow rate of 1.4 liters/min (3 cfh), except at the highest cooling rates, when flow rates of 37 liters/min (80 cfh) and 28 liters/min (60 cfh) were used during the cooling portion of the experiment. The cooling rate was defined as an average rate between 850 °C and 315 °C. The phase transformation temperature from austenite to the low temperature phase (martensite, bainite, and/or ferrite/cementite) was determined from a plot of temperature vs. dilation. An example of the temperature – dilation plot is shown in Figure 1. In this example, the sample was cooled at 2.1 °C/s and transformations were detected at 470 °C, 354 °C and 241 °C. Above 470 °C, the sample is austenitic. 100 Dilation (µ m) 80 60 40 20 o 470 C 0 o o 241 C 354 C -20 0 100 200 300 400 500 600 700 800 Temperature (oC) Figure 1. Change in sample length during cooling at 2.1 °C/s of Ancorsteel 4300. A reduction in slope represents the transformation to a lower density phase. The large change in slope at 241 °C is due to martensite formation. The transformation temperature(s) were correlated with the microstructure of the dilatometer specimens. The samples were crosssectioned, mounted, polished and etched using standard metallographic techniques. The fraction of different microstructural constituents in the samples (excluding porosity) was quantitatively determined using the point count method. The lower bainite morphology was defined as bainite. The remaining ferrite + carbide microstructures were defined as pearlite. Apparent hardness of the samples was measured in the center of the cross-sectioned face opposite that used for metallography. Results Typical chemical compositions of the two alloys are shown in Table I. The carbon content of each sample was measured after dilatometry testing. The average sintered carbon content is given in the table. Carbon contents were within ±0.02 wt% of that listed. The carbon contents of the thinnest samples (3.8 mm) contained the lowest carbon contents in this range due to a small amount of decarburization. Table I. Typical chemical compositions of the alloys tested (wt%). Alloy C Mn Si Ni Cr Mo Ancorsteel 4300 0.53 0.1 0.6 1 1 0.8 FLC-4608 0.8 0.1 1.8 0.5 Cu 2 The development of the continuous sinter cooling transformation diagram has been described by Semel (3). The diagram is based on a linear time scale and traces of four cooling profiles are shown along with their average cooling rates. The legend in each figure is as follows: A – austenite, M – martensite, B – bainite, P – pearlite. The solid black lines represent the transformation start temperatures for the various microstructures as measured in the dilatometer. The grey transformation start lines were not detected in the dilatometer and are interpretations based on the microstructures. Ancorsteel 4300 Hardenability Figure 2 shows the CSCT diagram for 4300. Three transformations are evident in the diagram. Pearlite formed at temperatures close to 500 °C over the range of cooling rates tested (0.6 °C/s to 3.1 °C/s). The pearlite in molybdenum containing P/M alloys, such as 4300, is not lamellar and is often referred to as divorced pearlite. Bainite and martensite were detected at 410 °C and 175 °C, respectively, at the slowest cooling rate. The pearlite and bainite start temperatures decreased as the cooling rate increased. The martensite start temperature was, however, found to increase with increased cooling rate. This result is consistent with earlier findings (4). The bainite transformation was not measured in the dilatometer at the 2.8 °C/s and 3.1 °C/s cooling rates, although a small amount of bainite was found metallographically. The bainite start line was extended (grey portion) to the 3.1 °C/s profile to indicate the presence of bainite. The microstructure of the sample cooled at 1.5 °C/s is shown in Figure 3. The microstructural constituents include martensite (M - light etching), lower bainite (B - plate, brown), coarse pearlite (P) and unresolved pearlite (UP). This alloy was found to have good hardenability, as evident from the microstructural results. More than half of the structure was martensitic at cooling rates > 1.5 °C/s, and the primarily martensite/bainite microstructure produced as-sintered hardnesses of 70 HRA (39 HRC) and higher. At cooling rates of 1 °C/s and below, one third of the microstructure remains martensitic, resulting in good hardness even at slow cooling rates. The CSCT diagram for 4300 sintered at 1260 °C was also generated, utilizing the same sintering conditions as used in reference 5. No significant differences were found between the two diagrams. The pearlite start temperature showed a slight decrease, about 25 °C, when the samples were sintered at 1260 °C. The overall shape of the diagram remained unchanged, along with the microstructures. At five of the seven cooling rates, the hardness values were the same on both diagrams. The effect of additional nickel on the hardenability of 4300 is dramatic. Results published in ref. 5 show alloy 4300 with the addition of 2 wt% Ni sintered at 1260 °C. The martensite content at 0.5 °C/s was 51%, with greater than 80% martensite at cooling rates of 1.5 °C/s and higher. The results are similar to those for Ancorloy MDC at a sintered carbon content of 0.6 wt% (4). The total alloy content of the 4300 + 2 wt% Ni is lower than MDC, showing the improvement in hardenability with the presence of chromium. 3 Temperature (C) 4300 - 0.53wt% Sintered Carbon at 7.1g/cm Continuous Sinter Cooling Transformation Diagram 900 800 700 600 500 400 300 200 100 0 Microstructure and Apparent Hardness Cooling Rate o A C/s 3.1 2.8 2.1 1.9 1.5 1.0 0.6 Ps Bs A+P o F/s 5.6 5.0 3.8 3.4 2.6 1.7 1.1 M B P Hardness % 83 75 67 56 48 34 30 % 12 12 19 20 24 26 11 % 5 13 14 24 28 40 59 HRA 73 73 71 70 68 67 64 A+B+P Ms M+B+P o 3.1 C/s 0 5 10 o 2.1 C/s 15 o 0.6 C/s o 1.5 C/s 20 25 Time (min) 30 35 40 45 Figure 2. CSCT Diagram for Ancorsteel 4300 + 0.53 wt% sintered carbon Figure 3. 4300 cooled at 1.5 °C/s. Martensite (M), bainite (B), pearlite (P) and unresolved pearlite / upper bainite (UP) morphologies are labeled. 3 Temperature (C) FL-4600 + 2%Cu + 0.8% Sintered Carbon at 7.0 g/cm Continuous Sinter Cooling Transformation Diagram 900 800 700 600 500 400 300 200 100 0 Microstructure and Apparent Hardness Cooling Rate o C/s 2.4 2.2 1.9 1.4 1.0 0.6 A Ps o F/s 4.2 3.9 3.4 2.5 1.8 1.1 M B P Hardness % 93 93 86 69 44 12 % 7 7 14 28 51 54 % 0 <1 <1 3 5 34 HRA 72 73 73 70 67 60 A+B+P A+B Ms M+B o 1.4 C/s o 2.4 C/s 0 5 10 15 M+B+P 20 25 Time (min) o 0.6 C/s 30 35 40 45 Figure 4. CSCT diagram of 4600 + 2 wt% Cu + 0.8 wt% sintered C (MPIF FLC-4608). Figure 5. Microstructures of FLC-4608 at 1.4 °C/s. Martensite (M) and bainite (B) morphologies are labeled. MPIF FLC-4608 is a standard prealloyed Ni-Mo sinter-hardening alloy, to which 2 wt% Cu is added. The CSCT diagram for this alloy is shown in Figure 4. This alloy has high martensite contents at the faster cooling rates, making it suitable for sinter-hardening. At 1.9 °C/s, the 4608 has 86% martensite and a hardness of 73 HRA (45 HRC), compared with 4300, which has 56% martensite and a hardness of 70 HRA (39 HRC) at the same cooling rate. At the rate of 1.4 °C/s, significantly more martensite is present in FLC-4608 (Figure 5) than Figure 3. Interestingly, at slow cooling rates (0.6 °C/s), the 4300 has better hardenability with 30% martensite and a hardness of 64 HRA compared with the 4600 with 12% martensite and 60 HRA. Overall, the FLC-4608 with 0.8 wt% sintered carbon has better hardenability than 4300 with 0.53 wt% sintered carbon. However, the higher carbon content required for this hardenability in the FLC-4608 alloy comes at a cost. The high carbon levels reduce mechanical properties in the material other than hardness. The ability to produce martensite at lower carbon contents is beneficial for properties such as toughness and fatigue. The good hardenability of the 4300 alloy without Cu and at lower carbon contents results in excellent overall properties (6). Another sinter-hardenable alloy system is based on FL-4800, which contains 1.4 wt% Ni, 1.25 wt% Mo and 0.4 wt% Mn. The FL-4800 alloy is specifically designed for sinterhardening applications, and the hardenability of this alloy system with varying levels of copper and carbon has been described by Semel (3). The 2 wt% Cu, 0.8 wt% sintered carbon composition (FLC2-4808) is extremely hardenable, with 90% martensite at a cooling rate of just 1.2 °C/s. The hardenability of the FL-4800 with 1 wt% Cu and 0.6 wt% sintered carbon is similar to the FLC-4608 shown above. The role of Mo and Mn on hardenability is apparent, as less copper and graphite are required to achieve similar levels of hardness in the FL-4800 system. The hardenability of FL-4800 base with 0.5 wt% C is much less than the 4300 alloy with a similar level of carbon (0.53 wt%). The hardness of FL-4805 at the maximum cooling rate (58 HRA) is lower than that of 4300 at the slowest cooling rate (64 HRA). The beneficial effect of Cr and Si on hardenability outweighs the reduction in Mo and Ni content. Conclusions Typical sinter-hardenable P/M steels are based on prealloys of Mo and Ni, to which Cu and graphite are admixed. Ancorsteel 4300 is a Cr and Si containing steel that does not require copper to enhance hardenability. The hardenability of 4300 was compared with a standard sinter-hardening grade (FLC-4608) utilizing continuous sinter cooling transformation diagrams. The lower carbon 4300 alloy exhibits good hardenability, with as-sintered hardnesses greater than 20 HRC at cooling rates typically found in production sintering furnaces. The good hardenability at lower carbon contents allows this alloy to be used in high performance applications. FLC-4808 has better hardenabilility with the addition of 2 wt% Cu and 0.8 wt% carbon, and is appropriate for traditional sinter-hardening applications. References 1. James, W.B., Causton, R.J., Baran, M.C., and Narasimhan, K.S., “New High Performance P/M Alloy Substitutes for Malleable and Ductile Cast Irons,” Advances in Powder Metallurgy & Particulate Materials, compiled by H. Ferguson and D. Whychell, MPIF, Princeton, NJ, 2000, part 13, p.123. 2. Baran, M.C., Chawla, N., Murphy, T.F., and Narasimhan, K.S., “New High Performance P/M Alloys for Replacing Ductile Cast Irons,” Advances in Powder Metallurgy & Particulate Materials, compiled by H. Ferguson and D. Whychell, MPIF, Princeton, NJ, 2000, part 13, p.133. 3. Semel, F. J., “Cooling Rate Effects on the Metallurgical Response of a Recently Developed Sinter Hardening Grade”, Advances in Powder Metallurgy & Particulate Materials, Compiled by V. Arnhold, C-L. Chu, W. Jandeska and H. Sanderow, MPIF, Princeton, NJ, 2002, part 13, p. 102. 4. Semel, F. J., “Ancorloy Hardenability”, Advances in Powder Metallurgy & Particulate Materials, Compiled by R. A. Chernenkoff and W. B. James, MPIF, Princeton, NJ, 2004, part 7, p. 50. 5. Lindsley, B., “Effects of Cooling Rate on the Hardenability of Chromium Containing P/M Steels”, Advances in Powder Metallurgy & Particulate Materials, Compiled by R. A. Chernenkoff and W. B. James, MPIF, Princeton, NJ, 2004, part 7, p. 62. 6. King, P., “Chromium Containing Materials for High Strength – High Fatigue Applications”, Euro PM2004, Ed. By H. Danninger and R. Ratzi, EPMA, Vol. 3, 2004, p. 165.