lecture8

Materials Science

04/10/20

1/4

Lecture 8

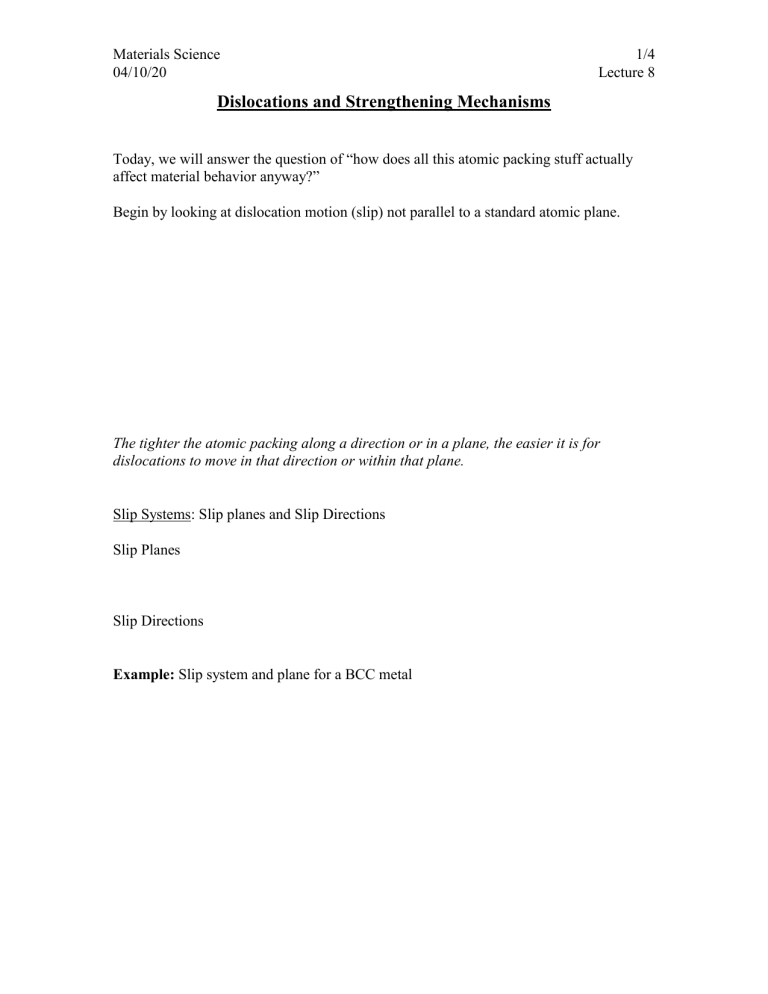

Dislocations and Strengthening Mechanisms

Today, we will answer the question of “how does all this atomic packing stuff actually affect material behavior anyway?”

Begin by looking at dislocation motion (slip) not parallel to a standard atomic plane.

The tighter the atomic packing along a direction or in a plane, the easier it is for dislocations to move in that direction or within that plane.

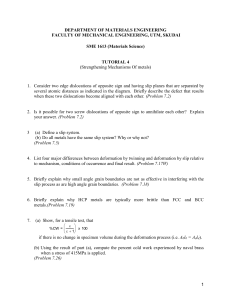

Slip Systems: Slip planes and Slip Directions

Slip Planes

Slip Directions

Example: Slip system and plane for a BCC metal

Materials Science

04/10/20

2/4

Lecture 8

FCC structures typically have 12 slip systems.

BCC structures typically have 12 slip systems

HCP structures typically have 3 slip systems

Question: Which one will be more brittle and which will be more ductile? Why?

Slip (dislocation movement) in a Crystals:

Brief Mohr’s Circle: The maximum shear stress resulting from a normal stress occurs at

45 degrees with respect to the normal stress.

Strengthening against deformation in Polycrystalline Materials:

Method 1: Grain size reduction:

How might grains affect slip (dislocation motion) in a material?

Hall-Petch Equation

Materials Science

04/10/20

3/4

Lecture 8

Method 2: Alloying materials for strength (solid solution strengthening)

The existence of a dislocation produces local tensile and compressive lattice strains in its vicinity.

Atoms in solid solution within the crystal may alleviate those strains.

Method #3: Cold working (strain hardening)

As the material is plastically deformed, more dislocations develop (higher _________ density).

Dislocations (on average) repel one another, impeding their motion.

Impeded motion of dislocation (slipping) makes material harder to deform

But …

Percent cold work:

Materials Science

04/10/20

4/4

Lecture 8

Basics of Heat Treating or Annealing

Cold working stores energy in the material in the form of lattice strains and increased numbers of grain boundaries.

Simple Heat treating (exposure to heat) can remove many of the effects of cold working.

The effects of heat treating vary with temperature and with time

Recovery

Recrystallization

Grain growth.