Tut-04_SME1613 - Faculty of Mechanical Engineering

DEPARTMENT OF MATERIALS ENGINEERING

FACULTY OF MECHANICAL ENGINEERING, UTM, SKUDAI

SME 1613 (Materials Science)

TUTORIAL 4

(Strengthening Mechanisms Of metals)

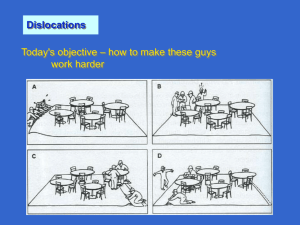

1. Consider two edge dislocations of opposite sign and having slip planes that are separated by several atomic distances as indicated in the diagram. Briefly describe the defect that results when these two dislocations become aligned with each other . (Problem 7.2)

2. Is it possible for two screw dislocations of opposite sign to annihilate each other? Explain your answer . (Problem 7.2)

3 (a) Define a slip system.

(b) Do all metals have the same slip system? Why or why not?

(Problem 7.5)

4. List four major differences between deformation by twinning and deformation by slip relative to mechanism, conditions of occurrence and final result.

(Problem 7.17W)

5. Briefly explain why small angle grain boundaries are not as effective in interfering with the slip process as are high angle grain boundaries. (Problem 7.18)

6. Briefly explain why HCP metals are typically more brittle than FCC and BCC metals.

(Problem 7.19)

7. (a) Show, for a tensile test, that

%CW =

1

x 100

if there is no change in specimen volume during the deformation process (i.e. A

0 l

0

= A d l d

).

(b) Using the result of part (a), compute the percent cold work experienced by naval brass when a stress of 415MPa is applied.

(Problem 7.26)

1

8. (a) What is the approximate ductility (%EL) of a brass that has a yield strength of 275MPa?

(b)What is the approximate Brinell hardness of a 1040 steel having a yield strength of 690

MPa?

(Problem 7.30)

9. Briefly cite the differences between recovery and recrystallisation processes.

(Problem 7.32)

10. Explain the differences in grain structure for a metal that has been cold worked and one hat has been cold worked and then recrystallised. (Problem 7.34)

11. Briefly explain why some metals (e.g lead and tin) do not strain harden when deformed at room temperature.

(Problem 7.35)

2