Questions on the Silicon Run I 2 Edition Video EE

Questions on the Silicon Run I 2 nd

Edition Video

EE-1301: Modern Electronic Technology

Friday, March 6, 2015

1. Name the semiconductor element being discussed in the video?

2. From what raw material can this element be extracted?

3. What percent of the earth’s crust is comprised of this element?

4. What is the name given to the small crystal that is used as a foundation to grow the large crystal?

5. What are dopants?

6. Name the two types of mobile charge carriers that are found in silicon?

The ____________ is positive; the _____________ is negative.

7. What happens when a silicon wafer is placed in a high-temperature furnace with oxygen or steam?

8. Name the four types of steps in wafer processing?

________________

________________

________________

________________

9. What kind of transistors are described in the video?

10. What metal is commonly used to interconnect the transistors in an integrated circuit?

Some words and definitions in the Silicon Run video:

Photolithography—the process of using photographic techniques to transfer the circuit patterns to physical structures on the wafer.

Photoresist—looks and pours like raspberry syrup. When coated on a wafer, it is a light sensitive material that changes on exposure to ultraviolet light and dissolves away when developed. The unexposed resist remains behind. Resist can withstand acid and etching.

Photomask—a photographic image of one of the layers of the circuit.

Photoresist can withstand the acids or the reactive plasmas of the etch step to permit the patterning of an insulating layer or a conductive layer. After removing the resist, the etched features of the silicon dioxide layer can withstand the high temperature steps of the process including oxidation and diffusion.

A wafer stepper uses a lens system to project images of the photomask onto the wafer at a reduced size.

Diffusion—using high temperature to cause dopant atoms to redistribute themselves.

Ion implantation—using particle accelerators to produce electric current beams of charged atomic nuclei to introduce precise amounts of dopant atoms into openings in the silicon dioxide. The video shows the loading airlock for the implanter system.

Dopants—impurities that are easily ionized within the semiconductor lattice to either donate an electron (five valence electrons) or accept an electron (donate a hole) (three valence electrons). Increasing the dopant density increases the conductivity. Boron introduces conductivity by positive holes (a p-type dopant). Arsenic and phosphorus (ntype dopants) introduce conductivity by negative electrons .

Etching can be done either by acids (wet etching) or by a plasma in partial vacuum (dry etching). Dry etching is preferable because the edges are more vertical and waste less space.

The process is called “isoplanar” because all steps take place from the top as though the circuit was a two-dimensional flat-plane entity, even though the actual transistor structures are three-dimensional in nature. Part of the isolating structures are recessed into the surface of the silicon wafer making the coverage of the surface topography easier to cover with the subsequent layers.

It takes the same number of steps to make two transistors as it does to make 200,000 transistors. A complete understanding of integrated circuits requires extensive study in mathematics, electrical engineering, physics and chemistry.

Answers to the questions:

1. Silicon.

2. Sand.

3. About 28%.

4. Seed.

5. Dopants are materials similar to silicon that introduce mobile charge carriers.

6. The “hole” is positive, the “electron” is negative.

7. A thin layer of silicon dioxide grows on the surface.

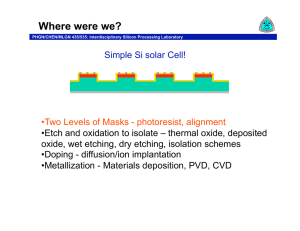

8. The four steps in Si processing—from the video.

1. Growth of thermal silicon dioxide.

2. Introduction of dopants.

3. Deposition of a variety of insulating and conducting films.

4. Precision patterning of all of these layers.

9. CMOS—complementary metal-oxide-semiconductor, field-effect transistors.

10. Aluminum (up through the ‘90’s), copper (since the ‘90’s).

______________________________________________________________________

The answer to question #8 in the video is slightly out of sequence. The correct sequence is as follows:

Silicon processing involves the following set of steps repeated many times through the process :

1. A thin layer of silicon dioxide is thermally grown; or, a thin layer of metal or insulator is deposited.

2. Photoresist is spun on, exposed and developed.

3. Exposed materials are etched away, after which the remaining photoresist is removed.

4. At a number of points in the process, dopant atoms are introduced into the exposed openings by ion implantation and/or diffusion.