Where were we?

advertisement

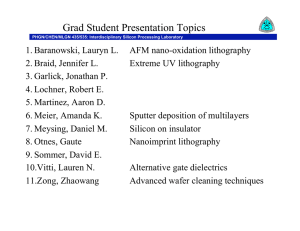

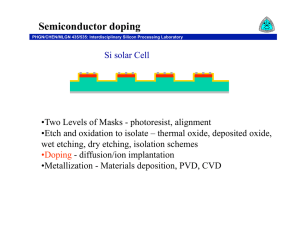

Where were we? PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Simple Si solar Cell! •Two Levels of Masks - photoresist, alignment •Etch and oxidation to isolate – thermal oxide, deposited oxide, wet etching, dry etching, isolation schemes •Doping - diffusion/ion implantation •Metallization - Materials deposition, PVD, CVD Conventional Optical Lithography PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Photolithography is how patterns are transferred into chips, and its the driving force behind Moore’s law. Light source and condenser Mask Projection/reduction optics Photoresist Substrate Photoresist - Basic Process PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Light: h Light: h Mask Photoresist Wafer Developing Photoresist Wafer Positive Resist Negative Resist Operating wavelengths, defines Resists PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Traditionally, the light sources have been high pressure Hg arc lamps (It’s what we use in this course). The aligner (why do we need to align?) filters out specific emission lines from the lamp for exposure of the photoresist •g-line - = 436nm •i- line - = 365nm (what we have) The drive to smaller feature size also means shorter wavelength. Why? 1) reduced absorption length 2) higher energy per photon 3) less diffraction 4) less refraction Generations after the above include (tend toward excimer laser light sources): •=248nm (KrF) •=193nm (state-of-the-art, ArF - 30nm features with high index immersion) •=157nm (F2 in development) Node (International Technology Roadmap for Semiconductors) PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory • • • • • • • • • • • • • 10 m — 1971 3 m — 1975 1.5 m — 1982 1 m — 1985 800 nm (.80 m) — 1989 600 nm (.60 m) — 1994 350 nm (.35 m) — 1995 250 nm (.25 m) — 1998 180 nm (.18 m) — 1999 130 nm (.13 m) — 2000 90 nm — 2002 65 nm — 2006 45 nm — 2008 • • • • 32 nm — 2010 22 nm — 2011 16 nm — approx. 2013 11 nm — approx. 2015 Photoresists - (the film in the camera) PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory 3 Component Material (relates to i-line and g-line) Matrix or Resin CH2 OH • Determines mechanical/chemical properties • Partially controls resistance to etching • Novolac – Industry Standard for + resist M OH PAC: Photo Active Compound • Changes properties due to optical exposure • Positive becomes soluble/Negative becomes insoluble • Controls exposure time/resolution Solvent • Dissolve the matrix and PAC • Determines Viscosity • Controls processing conditions (spin speed, time, bakes, etc.) M CH2 Photoresist Processing PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Wafer clean, dehydration, priming • Main Goal is Good Adhesion: Critical during developing and etching • Clean – device integrity • Dehydration – Organics are hydrophobic • Priming – Particularly important for oxides • HMDS: Hexa Methyl Di Silazane • Mist Chamber: Absorb a monolayer Organic Loving R Si HO Si O O H O H R H H OH O H H Water Loving Wafer Coating PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory #1: Dispensing Stage Not Critical • Few hundred RPM • Spread resist over wafer (65-85% solvent) #2: Acceleration Basically not a Problem • 2000-6000 RPM in a tenth of a second • Key to unifomity (solvents begin evaporating) #3: Spin Speed • Controls Thickness • Force Balance: Centrifugal vs. Viscous Drag #4: Spin Duration • Primary Goal is to Evaporate Solvent (30%) Photoresist Dependenttypically use manufacturers data sheets Softbake and Exposure PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Purpose of Softbake Step (80 – 110 ºC) • Drive-off solvent (5%) • Improve Adhesion • Anneal out stress in polymer film •Control film dissolution rate 2 Methods: • Hot plate: 30 – 60 seconds • Oven: 25 - 30 minutes • Considerations: Throughput, reproducibility Exposure • Depends on lamp intensity, spectrum • Depends critically on everything else, both before and after Post Exposure Bake? • Diffusion of PAC to remove standing waves •Chemically Amplified Resist, necessary to activate the photoacid generator Development and Hard Bake PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory Developer (positive DQN) • Aqueous NaOH/KOH Solution • Temperature Sensitive: +/- 1ºC • Bath or Spray • Time again depends on everything else Hardbake • Improves (hardens) Resistance • Detrimental to Profiles • Hotplate or Oven • Temperature Sensitive Photolithography in General • Complex multidimensional phase space • Requires careful optimization and tight process control Photoresist, the rest of the story PHGN/CHEN/MLGN 435/535: Interdisciplinary Silicon Processing Laboratory -Contrast curves, bleaching, planarization -Positive vs. Negative. Which is better? 1) positive 2) negative -Deep UV photoresists (Novolac absorbs below 250nm, PAC not capable of resolution below 250nm) -Chemically Amplified Resists (CAR) -Polymethyl methacrylate (PMMA) -Resists for Next Generation Lithography - Don’t exist -Environmental Issues?