hw8

advertisement

EE 147/247A

Fall 2015

Prof. Pister

Homework Assignment #8

Due by online submission Wednesday 10/28/2015 (Thursday at 9am)

1. Skim through “What is the Young’s modulus of silicon?” [1].

A. How much does the spring constant of a beam vary as the orientation of the axis of the

beam rotates 45 degrees on a (100) wafer?

B. How much does the resonant frequency vary? (use Figure 3 and/or Table VI)

2. Based on the data in “Etch rates for micromachining processing” [2]

A. Find an etchant that will attack silicon, but has an etch rate of “slow or zero” for

photoresist and aluminum.

B. What materials can be used to mask a KOH etch, assuming that you need a selectivity

better than 200:1?

3. Based on the data on the foldup paper crystal,

A. What is the range of silicon resistivity as dopant density ranges from 1014 to 1020

atoms/cm3?

B. What is the separation between surface atoms on a {100} face of a silicon crystal?

C. If you grow a thermal oxide for 10 minutes at 1000 C in H2O+O2 (“wet” oxidation), how

thick will it be?

D. What is the lattice constant (dimension of the unit cell) of this diamond lattice crystal?

How many atoms are in a unit cell? nb: Be careful counting fractional atoms in corners

and on faces. Based on these numbers, calculate the number of silicon atoms per cubic

centimeter.

4. Figure 1 below shows the “normal” results of KOH etching of (100) silicon – very flat sidewalls,

roughly on {111} planes. Reference [3] shows that etch fronts can look very different on the

way toward those final {111}-bounded pits if the mask features are not aligned with the <110>

directions.

A. With a rectangular mask aperture of dimension WxL, where W<L, oriented in the

direction of the wafer flat (as in Figure 1 below), what is the maximum depth of the

resulting KOH-etched pit if the selectivity to {111} planes were infinite?

B. In Figure 5 of [3], cross-sections AA and BB are on a standard (100) wafer. Other than

~54 degrees, what other sidewall angles are possible, what combination of mask layout

and processing is necessary to get them, and what crystal planes define them?

5. In this paper http://www.sciencedirect.com/science/article/pii/S0924424707008928 they

combine isotropic and anistropic etching to make an instrumented fluid pipeline over a pit. For

the KOH etch, sketch what you think the etch front would have looked like after the first few

microns of etching of the structure shown in Figures 4 and 5.

6. [247] Flip through a couple of MEMS journals or conference proceedings from cover to cover

(the library has journals, the BSAC conference room 402 Cory has journals and conference

proceedings and is open during the day, the internet will work too). Find at least two papers

where either:

A. the design or structure could have been built in a standard process but wasn’t

B. some aspect of the paper could be extended, refined, clarified, or otherwise improved by

designing and testing structures in a standard process

[1] M. Hopcroft, W. Nix, T. Kenny, “What is the Young’s modulus of silicon?”, JMEMS V19N2, April

2010.

[2] K. Williams, K. Gupta, M. Wasilik, “Etch Rates for Micromachining Processing – Part II”, JMEMS

V12N6, Dec. 2003.

[3] Brockmeier et al. “Surface tension and its role for vertical wet etching of silicon”, J. Micromechanics

and Microengineering, 2012.

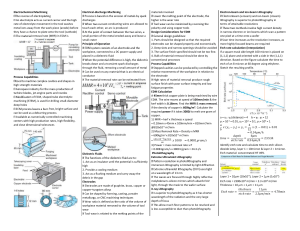

Figure 1 Examples of masks (left) and the resulting etch pits that they form (right) after KOH etching of

a (100) silicon wafer. [from: P. Pal, S. Singh, “A new model for etching characteristics of corners

formed by Si{111} planes on Si{110} wafer surface”, Engineering, Vol. 5 No. 11A, 2013.]