Document

advertisement

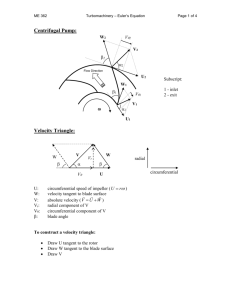

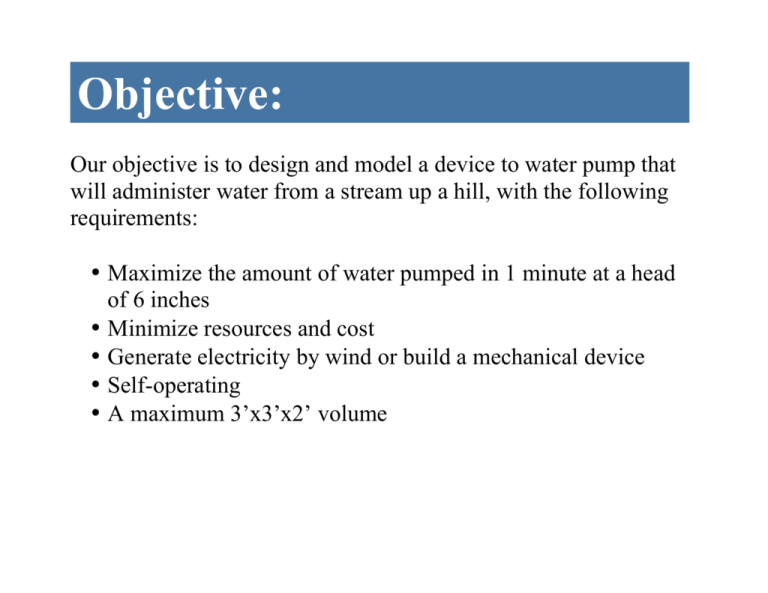

Objective: Our objective is to design and model a device to water pump that will administer water from a stream up a hill, with the following requirements: • Maximize the amount of water pumped in 1 minute at a head of 6 inches • Minimize resources and cost • Generate electricity by wind or build a mechanical device • Self-operating • A maximum 3’x3’x2’ volume Design: Our team designed a turbine to generate electricity for the pump. To keep the drag force low, we used 2mm thick PVC pipe with a length of 0.254m. The base of the blades 3.8 cm and were cut at an angle to 2cm. The edges of were sanded to help cut through the air and the natural curvature of the pipe helps propel the turbine around our circular hub, minimizing the drag. To produce more power with fewer rotations we constructed a gearbox [shown below] consisting of 2 parallel gear shaft and 4 gears resulting in a 1:11.11 ratio of rotation of the turbine to the rotation of the generator. Analysis & Testing: When placed 1 foot in front of a perpendicular fan producing a ! wind speed of 8.5( ! ) and 82.0 Watts, our turbine was able to produce a voltage of 3.25 V and a current of 0.04 A. The input power: Pin = V*A = 0.13 Watts. It was able to pump 0.4377 liters of !" ! !! ! (7.295𝐸 ! ! water at a flow rate of 7.295 ). The efficiency of the pump was 8.388% and the total cost of the device was $20.93 (including the pump and generator). Compared to the Betz’s limit, the turbine was 50% less effective than the maximum possible amount. (REUK.co.uk). However, the cost/efficiency is $249.52. Overall it was very successful. Conclusion: In this experiment, we were able to successfully create a running wind turbine. In doing this we were able to create enough power to pump 14.8 ounces of water in one minute. We created our wind turbine based of a full-scale wind turbine that has blades that are a total of 116 feet, ours were 10 inches giving it a scale of 5/696 feet (wind-watch.org). With this we can estimate that if our wind turbine was full scale we would be able to create 452.4 volts at any given time. Some of the issues we ran into while building the wind turbine is that before we had a bearing for the axle to spin in, the axle was spinning so fast that it was burning the wood and causing the axle to move down making the gears not line up. This was a huge problem because when the gears weren’t meshing correctly, the whole thing wouldn’t function properly. Another thing we found was that if the gears weren’t lined up properly, there was way too much friction making it near impossible for us to create enough power to pump the water up 6 inches. References: Betz Limit http://www.reuk.co.uk/betz-limit.htm Turbine Dimensions https://www.wind-watch.org/faq-size.php Materials & Construction: Material Generator Water Pump PVC Pipe Gears Wood Metal Rod Total Cost Cost $6.00 $10.00 $1.70 $1.95 $0.28 $1.00 $20.93 When choosing what materials and how we wanted to build our project, we thought about availability and durability of materials. We used PVC pipe because it is widely available in our workshop and because it is durable. While using PVC pipe we could make any shape we wanted to by connecting the PVC pipe to multiple joints making it really easy to make the shapes we wanted to. We also used wood to support the stand. The wood acted as a durable stand and was also very efficient product because of how cheap it is. The Village Project Water Pump Evan Wilmer, Jordan Lee, &Will Rooks S4c/d