CVE 240 – Fluid Mechanics

CHAPTER 7

ENERGY PRINCIPLE

Dr . Ercan Kahya

Engineering Fluid Mechanics 8/E by Crowe, Elger, and Roberson

Copyright © 2005 by John Wiley & Sons, Inc. All rights reserved .

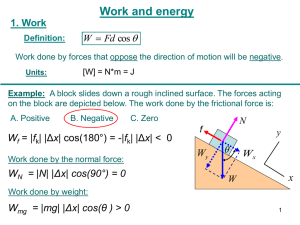

General Energy Consideration

E

T

α

1

V

1

2

2g

P

1

γ

z

1

α

2

V

2

2

2g

P

2

γ

z

2

h

P

h f

h t

Z: the position

P/ g: the pressure head

V 2 /2g: the velocity head h p

: head supplied by pump h t

:head given up to a turbine h f

: head loss

• local losses (bends, expansions, valves)

• frictional losses (function of pipe type, length) a : V elocity coefficient and can be set to unity for regular & symmetrical cross-section like pipe

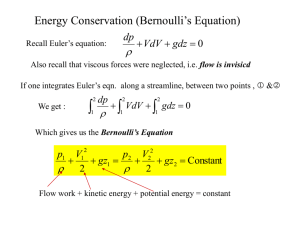

Bernoulli vs. Energy

V

1

2

2g

P

1

γ

z

1

V

2

2

2g

P

2

γ

z

2

Z is the position

P/ g is the pressure head

V 2 /2g is the velocity head

Relates velocity and piezometric pressure along a streamline, steady, incompressible, inviscid flow.

E

T

α

1

V

1

2

2g

P

1

γ

z

1

α

2

V

2

2

2g

P

2

γ

z

2

h

P

h f

h t

Relates energy at two points for viscous, incompressible flow in a pipe, with accounting for additional energy addition / extraction

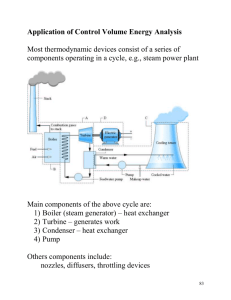

Energy Principle

• So far, mechanical forces on a fluid

– Pressure

– Gravity

– Shear Stress

• Considering Energy, we can solve:

– Power required to move fluids

– Effects of pipe friction

– Flow rates of fluids moving through pipes & orifices

– Effects of obstacles, bends, and valves on flow

First Law of Thermodynamics

E

Q

W

• E = energy of a system

• Q = heat transferred to a system in a given time t

• W = work done by the system on its surroundings during the same time

• Energy forms:

Kinetic and Potential energy of a system as a whole and energy associated with motion of the molecules

( atomic structure, chemical energy, electrical energy )

E = E k

+ E p

+ E u dE

Q

W dt

Involves sign convention:

+ heat transferred to the system

+ work done by the system

- heat transferred from the system

‐ work done on the system

First Law of Thermodynamics

Derivation of Energy Equation

Reynolds Transport Theorem applied to First Law of

Thermodynamics e

e k

e p

u

E : extensive property of the system e : intensive (energy per unit mass) dE dt

d dt cv

e

dV

cs

e

V .

dA

Q

W

d dt cv

e

dV

cs

e

V .

dA e e p k

V

2

2 gz u

internal energy

Flow Work

Work is classified as: (work) = (flow work) +(shaft work)

Flow Work : Work done by pressure forces as the system moves through space

Force (F) = p A

Work = F

l

= (pA) (V

t )

W f

cs pV .

A

At section 2, work rate done on surrounding fluid is

At section 1, work rate done by surrounding fluid is

→

V

→ - V

2

1 p

2 p

1

A

2

A

1

Shaft Work

( any work not associated with a pressure force!

)

• Work done on flow by a pump

– increases the energy of the system, thus the work is negative

• Work done by flow on a turbine

– decreases the energy of the system, thus the work is positive

Reynolds Transport Theorem : Simplified form

If the flow crossing the control surface occurs through a number of inlet and outlet ports, and the velocity v is uniformly distributed (constant) across each port; then

Q

W

m o

(

V o

2

2

gz o

h o

)

m i

(

V i

2

2

gz i

h i

)

Steady-Flow Energy Equation

.

Q = rate of heat transfer TO the system (input)

.

W = rate of work transfer FROM the system (output)

.

m = rate of mass flow h = specific enthalpy (h = u + p/ ρ)

Example 7.2:

If the pipe is 20cm and the rate of flow 0.06m

3 /s, what is the pressure in the pipe at L=2000m? Assume h l

=0.02(L/D)V 2 /2g

α

1

V

1

2

2g

P

1

γ

z

1

h p

α

2

V

2

2

2g

P

2

γ

z

2

h t

h l

This energy equation assumes steady flow & constant density

Power Equation

Let’s relate “head” to “power & efficiency”

Pump power:

W p

g

Qh p

m gh p

Power delivered to turbine:

W t

g

Qh t

m gh t

Both pump & turbine lose energy due to friction which is accounted for by the “ efficiency ” defined as the ratio of power output to power input.

P output

P input

If mechanical efficiency of the turbine is η t , the output power supplied by the turbine:

W s

t

W t

Example 7.4: Power produced by a turbine

α

1

Discharge Q = 14.1 m 3 /s ; Elevation drop = 61 m

Total head loss = 1.5 m ; Efficiency = 87% Power = ?

V

1

2g

2

P

1

γ

z

1

h p

α

2

V

2

2g

2

P

2

γ

z

2

h t

h l

Evaluations:

V 1 = V 2 = 0 p 1 = p 2 = 0 z 1 -z 2 = 61m h t

= (z

1

-z

2

) - h

L

= 61 – 1.5 = 59.5 m

Power equation:

P input

to

turbine

g

Qh t

= (9810 N/m3) (14.1 m3/s) (59.5m)

= 8.23 MW

Efficiency equation:

P output

from

generator

P input

to

turbine

= 0.87(8.23 MW) = 7.16 MW

Application of the Energy, Momentum and

Continuity Principles in Combination

α

1

V

1

2

2g

P

1

γ

z

1

α

2

V

2

2

2g

P

2

γ

z

2

h f

Fs

m V

2

m V

1

Neglecting the force due to shear stress p

1

A

2

p

2

A

2

γA

2

LSin α ρ Q (V

2

V

1

)

Sudden expansion head loss h f

V

1

V

2

2

2 g

Example 7.5: Force on a contraction in a pipe

Find horizontal force which is required to hold the contraction in place if

P

1

=250kPa ; Q=0.707m

3 /s & head loss through the contraction h f

0 .

1

V

2

2

2 g

Assume α

1

= α

2 = 0 (kinetic energy correction factor)

SOLUTIONS:

Q , p

1

, V

1 and V

2

: known

Fx and p

2

: unknown

To obtain unknown p

2: p

1

A

1

p

2

A

2

F x

m

2

V

2

m

1

V

1

α

1

V

1

2

2g

P

1

γ

z

1

α

2

V

2

2

2g

P

2

γ

z

2

h f

Q

A

1

V

1

A

2

V

2

HYDRAULIC & ENERGY GRADE LINES

GRADE LINE INTERPRETATION - PUMP

GRADE LINE INTERPRETATION TURBINE

GRADE LINES - NOZZLE

GRADE LINES - PIPE DIAMETER CHANGE

GRADE LINES - SUB-ATMOSPHERIC PRESSURE

CLASS EXERCISE: Q7.32

Find the head loss btw the reservoir surface and point C.

Assume that the head loss btw the reservoir surface and point B is three quater of the total head loss.

CLASS EXERCISE: Q7.36

CLASS EXERCISE: Q7.60

CLASS EXERCISE: Q7.71