tire manufacture and the art of innovation

advertisement

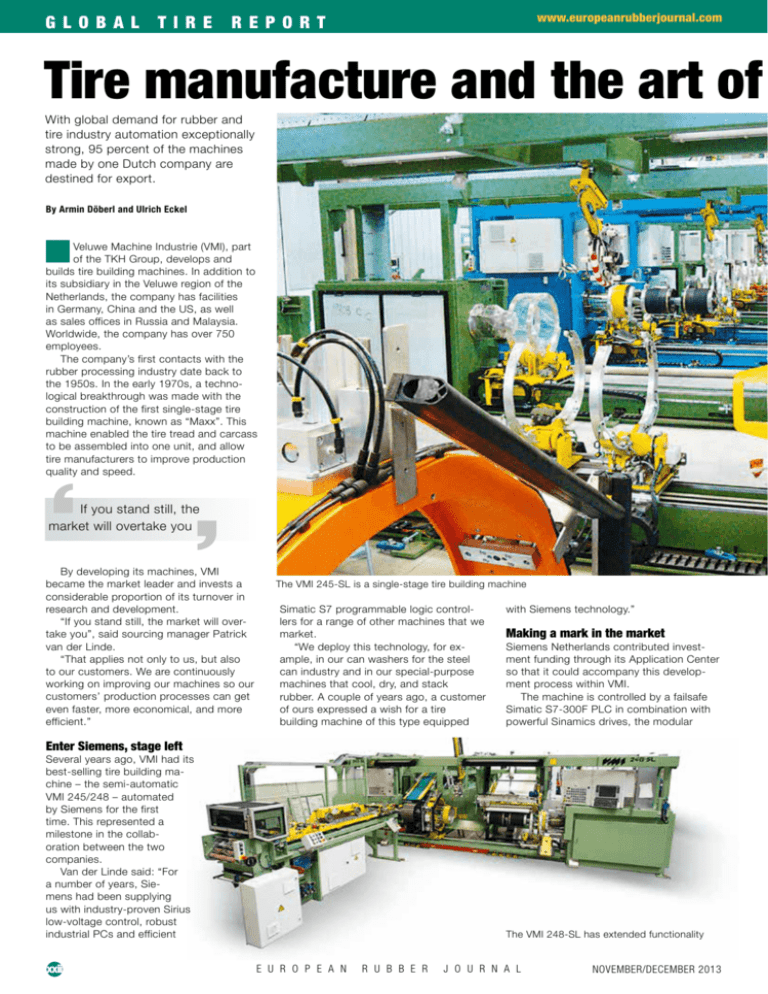

g l obal ti re www.europeanrubberjournal.com repo rt Tire manufacture and the art of With global demand for rubber and tire industry automation exceptionally strong, 95 percent of the machines made by one Dutch company are destined for export. By Armin Döberl and Ulrich Eckel Veluwe Machine Industrie (VMI), part of the TKH Group, develops and builds tire building machines. In addition to its subsidiary in the Veluwe region of the Netherlands, the company has facilities in Germany, China and the US, as well as sales offices in Russia and Malaysia. Worldwide, the company has over 750 employees. The company’s first contacts with the rubber processing industry date back to the 1950s. In the early 1970s, a technological breakthrough was made with the construction of the first single-stage tire building machine, known as “Maxx”. This machine enabled the tire tread and carcass to be assembled into one unit, and allow tire manufacturers to improve production quality and speed. ‘ If you stand still, the market will overtake you ’ By developing its machines, VMI became the market leader and invests a considerable proportion of its turnover in research and development. “If you stand still, the market will overtake you”, said sourcing manager Patrick van der Linde. “That applies not only to us, but also to our customers. We are continuously working on improving our machines so our customers’ production processes can get even faster, more economical, and more efficient.” The VMI 245-SL is a single-stage tire building machine Simatic S7 programmable logic controllers for a range of other machines that we market. “We deploy this technology, for example, in our can washers for the steel can industry and in our special-purpose machines that cool, dry, and stack rubber. A couple of years ago, a customer of ours expressed a wish for a tire building machine of this type equipped with Siemens technology.” Making a mark in the market Siemens Netherlands contributed investment funding through its Application Center so that it could accompany this development process within VMI. The machine is controlled by a failsafe Simatic S7-300F PLC in combination with powerful Sinamics drives, the modular Enter Siemens, stage left Several years ago, VMI had its best-selling tire building machine – the semi-automatic VMI 245/248 – automated by Siemens for the first time. This represented a milestone in the collaboration between the two companies. Van der Linde said: “For a number of years, Siemens had been supplying us with industry-proven Sirius low-voltage control, robust industrial PCs and efficient xxii The VMI 248-SL has extended functionality E U RO P E A N R U BBER J O U RN A L november/december 2013 www.europeanrubberjournal.com innovation g lo b a l now has customers for whom the Siemens technology is a basic requirement. VMI also has a “Bead Apex” machine model which uses this technology. This joins a tire bead to hard rubber (apex), which is then used in the VMI 245/248. Stand or fall VMI’s reputation depends on the “superior technical expertise” that it draws principally from its supplier market. High demands are made upon these suppliers, and the company implements a structural check using its QLTC principle: Quality, Logistic Performance, Technology and Cost. Its production facilities around the world are supplied with high-quality products that arrive “just in time” (L), in accordance with the given specifications and quality requirements (Q). The company also makes every effort to purchase these products and services at the most attractive price (C) in the supply chain. To implement this, any faults or excessive consumption of resources in this chain must be identified and cleared. In many cases, this means that the products and services have to be bought locally. Good chimes VMI’s experiences with Siemens on product quality and logistics have been good. “Siemens supplies long-lasting and reliable technology, taking into account the Simatic ET200 I/O system, and energy-saving Simotics servomotors. This automation, as part of the totally integrated automation (TIA) concept, accompanies the entire machine production process. These coordinated components raise efficiency levels and improve the competitive capability of products on a sustainable basis. The machine manufacturer has since built dozens of machines using this drive and control technology. With a second supplier in the field of drive and automation technology for tire building machines, VMI is stronger and november/december 2013 ti r e r e p o rt applicable laws and regulations,” said van der Linde. “In the Netherlands, we order the necessary parts through Siemens’ Industry Mall. We have created a link to our own E-portal for our suppliers, thus the order data can be read from our system and into the Industry Mall in one go. This chimes very well with our concept of lean production; we do not see why the customer should have to pay for us entering all the data by hand. “One further positive aspect is the global network that Siemens operates. We can use this to supply our widely distributed production facilities promptly and with low delivery charges.” Staying in front Several years ago with the “Maxx” series, VMI brought the first fully automatic tire building machines onto the market. Recently the company also launched the successor to the VMI 24x series − the “Exxium”. These two series of machines now offer a considerably higher production speed, thanks to a higher degree of automation, which in turn delivers a higher output of n tires on a daily basis. Both authors work for Siemens AG in Germany. Armin Döberl is part of the Industrial Automation Systems unit in Nuremberg. Ulrich Eckel works in the Motion Control Systems unit based in Erlangen. The Simatic S7-300F programmable logic controller is suited to innovative system solutions E U RO P E A N R U BBER J O U RN A L xxiii