Managing Process Changes at the University of Central Florida

advertisement

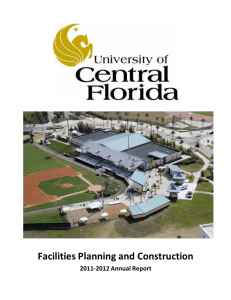

Managing Process Changes at the University of Central Florida By: Dave Norvell, Assistant Vice President for Facilities, University of Central Florida Richard Overman, CMRP, Reliability Professional, Alidade MER, Inc. President Dr. Charles N. Millican President Dr. John C. Hitt Enrollment Total 58,587 students Original Enrollment 1,948 students Degree Programs 211 Total degrees awarded 232,144 AY 10-11 Credit Hours 1,449,115.0 FTIC Applicants 25,671 FTIC Acceptances 10,604 Average SAT 1250 (1840) Average HS GPA 3.9 FY 2011 Research Funding $106.6 M • Industry $37 M • State $12.2M • Federal $57.4M UCF regarded to have “very high research activity“ The Carnegie Foundation, 2011 Notable, recent research contributions to: optics, modeling and simulation, digital media, engineering and computer science, business administration, education, and hospitality management. UCF Athletics was founded during the 1969-70 season • Varsity sports teams 16 • NCAA Division Conference USA • Honor Roll Student Athletes 1048 • Average team-GPA 3.0 2010 AutoZone Liberty Bowl Champions 2007, 2010 Conference USA Championships 2005, 2007 and 2010 Conference USA East Division Championships 2003, 2007 Spirit Teams - National Companions Our Campus Main Campus 1,415 acres Regional Campuses 10 Main campus buildings 180 Gross square footage 9 M Housing Total 10,276 beds Employees Total 10,567 Operating Budget $1.4 B Need for Change • Decision to make significant changes to Facilities group was made in 2011 • New management took a hard look at the situation • FO services and capabilities – Had not kept pace with the rapid growth – Was unable to maintain performance under existing conditions – Struggling to meet the needs of their customers in every area. • Review revealed that all parts of the faculties group needed to change 7 Need for Change • Order in which the changes would take place – – – – – • CMMS software Maintenance Landscaping Housekeeping Facilities Planning and Construction Issues – – – – – – – Too many personnel Too much supervision Too many levels of supervision Inadequate core competency throughout much of the department. Extremely reactive Few performance measures Little accountability for results. 8 Software Selection • Reviewed software used by other large higher education institutions • Review compared UCF software needs and various software alternatives • Decision was made to go with AiM software produced by AssetWorks – Used by many universities in North America – Considered one of the premiere CMMS software suites in facilities management – Has various modules that could meet needs of multiple departments – Has an integrated work planning and scheduling module – Capability to perform electronic dispatching of the work force 9 CMMS not Total Solution • Just implementing a new CMMS not the total solution • Reliabilityweb.com survey (2011) found that – 91% said work order management (WOM) system is the most important feature of CMMS software – 34% say their WOM process is working well – 78% did not achieve anticipated return on investment (ROI) goals – 50% no ROI achieved, 28% did not achieve anticipated ROI • Behavioral research found little evidence that information systems automatically transform organizations • Information systems instrumental in accomplishing behavior changes only when management holds the organization accountable to accomplish the outcome 10 Enhancing Change Management • Organizational change management not UCF management core business • No time to do regular work and make organizational changes • Selected change management consultant to guide the process – – – – Alidade MER, Inc. chosen Experience with other large universities Experience with AiM Philosophy of ensuring • Right processes are in place • Processes are under control • Processes are stable • Alidade MER brought in to facilitate design and implementation of new work management process 11 Reactive to Proactive • Designing, implementing and maintaining processes that provide control and stability is a prerequisite to transitioning from a reactive environment to a proactive environment • UCF was very reactive and needed to become proactive • Performance improved by implementing effective and efficient work management processes • Largest benefits attained through planning and scheduling of work • As new process were established and sustained – Managers and supervisors able to hold people accountable – Able to collect and analyze work order completion, and equipment performance information – Able to have continuous improvement process – Improved worker performance – PM completion and resources linked to specific assets. 12 13 Framework for Control & Stability • Control & Stability Generates Actionable Information (symptoms) – Optimizes human resources – Generates data – Data becomes information • Proactive Reliability used to Analyze & Solve Important Issues (diagnosis) – Reliability Improvement Prioritization chews on the info – Reliability in Design defines improvements – Reliability in Operations manages change, training, documentation & standards • Implement Improvements (prescription) – Improvements are transfused back into normal routine – Control & Stability Realm generates new data 14 Performance Optimization Model Performance Optimization is a means to structure and define implementation, and to sustain high performance. • Information + Action = Desired Behaviors • – Processes and accountability are defined – Process & behavior measures are monitored – Positive reinforcement and corrective coaching are provided to guide behaviors Desired Behaviors x Time = High Performance – Leadership acumen & accountability – Consistent and continuously improving behaviors – High performance is achieved 15 Information Guidance Information Policies, Processes, Procedures Describes what needs to be done and how Performance Information Process & Behavior Measures Information on past and current performance Flow Charts, RASI Tables and Process Guides document what is intended, and provides training content. 16 Action Guidance Action Continuous Improvement of Policies, Processes and Procedures Maintain guidance to ensure standards are current Performance Action Analyze Process & Behavior Measures Act through leadership and management skills Leadership with Management of Change: Keep guidance current and support process and accountabilities. New Process Implementation • Similarities and differences in how each department approached development and implementation of new processes and organizational structures. • Similarities – Guiding team provided the overall direction and goals – Guiding team chartered a process design team that was empowered to develop new work management processes and organizational structure – Process design team included departmental supervisors and line employees – Process design team provided policy recommendations to guiding team – New processes and organizational structure approved by guiding team 17 Maintenance Department • Organizational structure changed from a trade shop format to a zone organizational structure • Implementing pilot zone to test new processes • Processes changes and a second pilot zone was implemented • Rest of zones implemented for core campus • Remaining remote campus shops and housing maintenance will be implemented in the coming months 18 Old Organizational Structure 19 New Organizational Structure 20 What’s Been Achieved by the Zones? Measure Initial Current Difference WO/Day-FTE Z1 1.4 4.9 250% increase WO/Day-FTE Z2 1.4 4.5 221% increase Hrs/Day-FTE Z1 Charged to WOs 2.6 6.9 165% increase Hrs/Day-FTE Z2 Charged to WOs 2.6 6.5 Hrs Scheduled per FTE per day Z1 NA 7.8 Goal 7.5 Hrs Scheduled per FTE per day Z2 NA 6.2 Goal 7.5 Span of Control 6:1 9:1 8 to 12:1 Square Footage per FTE 83,000 102,000 23% increase Z1=Zone 1, Weekly avg. during July – September Z2=Zone 2, Weekly avg. during August-September 150% increase Control & Stability Taking Hold in 2 Zones • Processes have been redesigned • Accountability and responsibilities identified • Training in new roles and responsibilities completed • Work flow and codes have been aligned with AiM • Mobile computing has been initiated • Planning & Scheduling has been initiated • All workforce hours are accounted for. • All work is 22 accounted for. Landscaping and Natural Resources (LNR) • LNR had well working organizational structure • New processes needed and implemented • New processes developed and implemented when LNR master data set up in CMMS 23 Housekeeping Housekeeping took an all-in approach Reorganized into zones similar to maintenance zones Implemented them all at once rather than starting with a pilot zone A big issue was the ineffectiveness of supervisory leadership New Coordinators hired All existing senior leadership became supervisors Number of housekeepers on staff had not kept pace with the growth of the university • APPA staffing standards used to analyze gaps and justify hiring 50% more housekeepers • Worked with HR to hold job fares to facilitate this massive hiring • • • • • • • 24 Old Organizational Structure 25 New Organizational Structure 26 Facilities Planning and Construction (FPC) • FPC issues – Organizational structure – Processes – Abilities of Project Management staff • New processes and organizational structure implemented all at once • Needed to replace majority of staff with new hires 27 Lessons Learned #1 • • • • Tempting to try this on your own You are not in change management business Bring in experienced people UCF greatly benefited from partnering with Alidade MER 28 Lessons Learned #2 • Be prepared to make changes “on the fly” • Need to be flexible to new information to accommodate new learning • It was helpful to implement the new process in one pilot zone first • Piloting provided ability to see how it worked before implementing with the whole staff • Pilot zone provided controlled environment to make changes to see how they worked • Even with pilot zone management must be prepared for the unexpected • Well designed process will allow for dealing with unexpected situations • Figure out best way to use the process for unexpected situation 29 Lessons Learned #3 • Good communication very important • The more everyone knows what is going on, the more quickly changes can be made and a new normal established • Communication with customers and managing their expectations is a must • Easy to get caught up in managing the change and forget about those outside the process that are affected by the change 30 Lessons Learned #4 • Anticipate and plan for possible increased operational expenses • Because more maintenance will be performed, material costs will initially increase • Cost savings is the expectation, initial cost increases should also be anticipated • These cost increases must be viewed as short term affects • Long term cost go down. 31 Lessons Learned #5 • Expect push back from some staff • Technicians and managers do not like change • Could be from – fear of losing their job – big brother watching – taken out of their comfort zone • The more that is explained to the staff the more they will understand what is going on • They may not like it but at least they will understand what is happening and how it will affect them 32 Lessons Learned #6 • Need to revise current and/or develop new policies/procedures • In some cases, the policies and procedures needed to be changed anyway • In other cases, the new process demands new procedures. 33 Lessons Learned #7 • iTouch mobile devices revealed weaknesses in IT infrastructure • iTouch relies on the availability of a wide area network (WiFi) • UCF WiFi was unreliable in much of the campus – Line employees had to spend time looking for a hot spot – logging into network multiple times a day to manage work orders in CMMS 34 Lessons Learned #8 • Reorganizing into zones meant that all employee’s job description had to be rewritten • This can take some time • Best to partner with HR to get this done efficiently • Some were employees moved to different shifts and some had compensation changes. 35 Lessons Learned #9 • Installation of a new CMMS had many challenges • Avoid “dumping” bad information from the old CMMS into the new CMMS • Asset information and PM procedures need to be verified and validated before being put into new CMMS 36 Lessons Learned #10 • It would have been better to design the work flow process before implementing the new CMMS so the CMMS implementation can be done to fit the process • Because CMMS was implemented first, UCF had to reset important fields in the CMMS after the fact • Significant amount of rework. 37 Lessons Learned #11 • Make sure that there is adequate strength in all of the trades to be spread out over all of the zones before moving from a central shop to a zone organizational structure 38 Lessons Learned #12 • Don’t underestimate the challenges that shop foremen will have in learning to be multi-trade supervisors • Many foremen had not been asked to be accountable for their shop mates to the level of accountability required for control and stability • Best to determine if your foremen and supervisors are qualified for these new responsibilities before making assignments 39 Results to Date • Labor hours to be more accurately documented to specific assets • Visibility of who is working on what jobs and how much time each is taking has been dramatically improved • More accurate and expedited recovery of charge back costs • Greater awareness by staff of the importance of accountably • Technicians knew which of their colleagues were not “pulling their weight” • One technician commented “we are finally getting some work out of [him]” 40 Results to Date • Increased accountability and process controls continue to develop competiveness and “esprit de corps” • Implemented recognition programs; such as a “maintenance team of the month” award to foster the spirit of continuous improvement • More accurate and detailed accounting of operational expenses • Information used for developing budgets, making staffing decisions, and defending resource requirements to upper management • Easier to train/coach current and new staff • Information needed to identify the trade skills that are needed, or that need to improve • Able to adjust the number of people in each trade to meet the maintenance requirements 41 Conclusion • Changes have been both dramatic and rewarding • UCF Facilities Operations group looks a lot different than it did two years ago • Rough spots and need to smooth customer’s feathers but improvements are obvious and continuing • The journey is not complete but UCF is on the right road and making good progress • Better able to perform its mission of providing “…the University of Central Florida with comprehensive maintenance standards in order to maximize the efficiency and reduce the overall cost of maintaining facility structures, equipment, and infrastructure” in a more efficient, effective way with fewer resources and lower costs 42