MaintenanceManagement

Maintenance management

1

Maintenance Management Loop

Study preparation RAMS requirements

Failure modes and effect analysis

Maintenance types and intervals

Data Analysis and improvement analysis

Database

Overall operation, mainteance and repair

Res tr ic tion s

Reporting Acutal maintenance and inspection

2

Fai

Dev lur es iati on s

Grouping of maintenance activities

Maintenance and inspection plan

FMEA/FMECA

Failure Mode, (Criticality) and Effects Analysis

A Failure Mode and Effects Analysis is often the first step in a systems reliability study

It involves reviewing as many components, assemblies and subsystems as possible to identify possible failure modes and the causes and effects of such failures

For each component, the failure modes and their resulting effects on the rest of the system are written onto a specific

FMCEA form

FMECA is an important element of RCM

3

Maintenance and inspection types and intervals

The main objective of this step is to determine the type and frequencies of maintenance and inspection tasks

In principle each failure mode/failure cause in the FMECA should be combated by a maintenance task

The RCM logic of an RCM analysis will be a starting point for identifying relevant maintenance tasks

To determine optimal frequencies of maintenance tasks it is usually required to establish a cost model to optimize

4

Grouping of maintenance and inspection work

When the maintenance tasks are identified, and frequencies set it will usually be natural to group these activities into maintenance packages, each package describing what to do, and when to do it

It is a challenge to establish such an optimal grouping strategy

Why grouping

Save “set-up” cost

Convenience

5

Maintenance and inspection plan

A maintenance program shall be established, which includes written procedures for maintaining, testing, and repairing the various components

Such a program is often implemented by a computerized maintenance management system (CMMS)

A main task of the CMMS is to manage all work orders for preventive maintenance

6

Failures need corrective maintenance

Failures represent technical component failures (e.g. rail breakage, defect breaks etc), and deviations (e.g. geometrical deviations of the track)

Failures and deviations require repair, overhaul etc

Typically a work order for corrective maintenance (CM) is issued

The CMMS will also manage these work orders

7

Reporting of result from maintenance and inspection

All maintenance work (functional testing, preventive maintenance, and corrective maintenance) shall be reported into an electronic maintenance database

The information to report depends on the type of maintenance work

Important information to report

Exact description of failed/maintained unit

Failure mode (CM)

Component state (PM)

Failure cause (CM)

Effect of failure (CM)

Direct cost of maintenance action

8

Database

The database used in the maintenance management loop is a conceptual term

A RAMS database may be realized as a part of the CMMS

It is essential that the database system contains necessary information for a proper data analysis

9

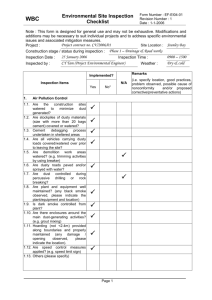

Data analysis and improvement analysis

A proper failure cause analysis (FCA), or root cause analysis (RCA)

Investigation into the failure reports to identify common cause problems (CCF)

Updated reliability data that was used in quantitative risk analyses/maintenance optimization models

Verification of assumption related to safety critical functions/safety barriers

10

Restrictions

When maintenance comes out of control (large backlog) it is important to initiate operational restrictions

Closing a railway line

Reducing speed

Stop production

Use of compensating measures

Restrictions will also be necessary when the system integrity is threatened by weather conditions such as rain, frost, snow, high temperature etc.

11

Exercise

What is meant by “the maintenance management loop is

NOT closed”

12