Project Proposal

advertisement

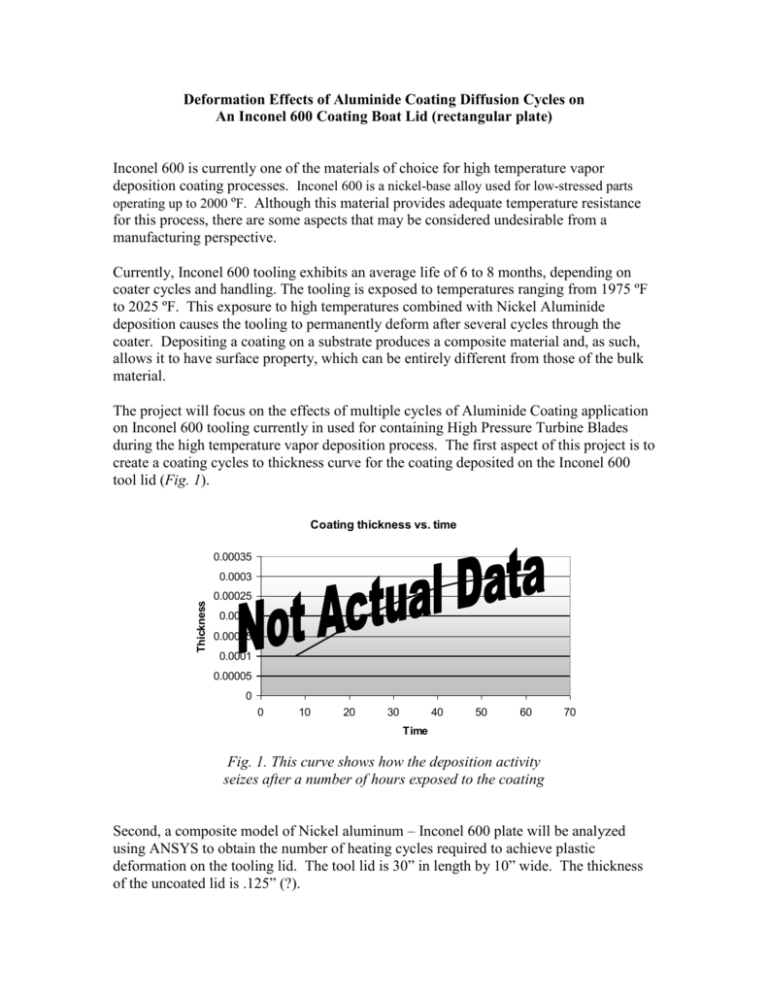

Deformation Effects of Aluminide Coating Diffusion Cycles on An Inconel 600 Coating Boat Lid (rectangular plate) Inconel 600 is currently one of the materials of choice for high temperature vapor deposition coating processes. Inconel 600 is a nickel-base alloy used for low-stressed parts operating up to 2000 ºF. Although this material provides adequate temperature resistance for this process, there are some aspects that may be considered undesirable from a manufacturing perspective. Currently, Inconel 600 tooling exhibits an average life of 6 to 8 months, depending on coater cycles and handling. The tooling is exposed to temperatures ranging from 1975 ºF to 2025 ºF. This exposure to high temperatures combined with Nickel Aluminide deposition causes the tooling to permanently deform after several cycles through the coater. Depositing a coating on a substrate produces a composite material and, as such, allows it to have surface property, which can be entirely different from those of the bulk material. The project will focus on the effects of multiple cycles of Aluminide Coating application on Inconel 600 tooling currently in used for containing High Pressure Turbine Blades during the high temperature vapor deposition process. The first aspect of this project is to create a coating cycles to thickness curve for the coating deposited on the Inconel 600 tool lid (Fig. 1). Coating thickness vs. time 0.00035 Thickness 0.0003 0.00025 0.0002 0.00015 0.0001 0.00005 0 0 10 20 30 40 50 60 70 Time Fig. 1. This curve shows how the deposition activity seizes after a number of hours exposed to the coating Second, a composite model of Nickel aluminum – Inconel 600 plate will be analyzed using ANSYS to obtain the number of heating cycles required to achieve plastic deformation on the tooling lid. The tool lid is 30” in length by 10” wide. The thickness of the uncoated lid is .125” (?). This curve combined with an ANSYS model will result in predicting the tool’s service life. Being able to better understand and predict the tool service life for the Inconel 600 tooling will result in the ability to create a forecast for when the tools need to get replaced. Other than obtaining the literature and writing up the body of the report. The following 6 milestones have to occur in order to finalize this project by the date required. Dates M1 – Obtain Inconel 600 scrap parts from tooling vendor – 01/31/2008 M2 – Get familiarized and learn how to use the ANSYS software – Start 01/31/2008 M3 – Obtain operations window introduce the Inconel 600 pieces into the coating boats – Start 01/30/2008 M4 – Run the final element analysis on the lid (rectangular plate) - ? M5 – Obtain and tabulate thickness data from the laboratory - ? M6 – Compile and analyze the results – April 2008 Reference: Pierson, H.O. (1999). Handbook of Chemical Vapor Deposition - Principles, Technology and Applications (2nd Edition). William Andrew Publishing/Noyes. Shreir, L.L.; Jarman, R.A.; Burstein, G.T. (1994). Corrosion (3rd Edition) Volumes 1-2. Elsevier. Bunshah, R.F. (1994). Handbook of Deposition Technologies for Films and Coatings Science, Technology and Applications (2nd Edition). William Andrew Publishing/Noyes. McEvily, Arthur J. Metal Failures - Mechanisms, Analysis, Prevention. John Wiley & Sons. Milne, I.; Ritchie, R.O.; Karihaloo, B. Comprehensive Structural Integrity, Volumes 110. Elsevier.