NiCoTef-Coating

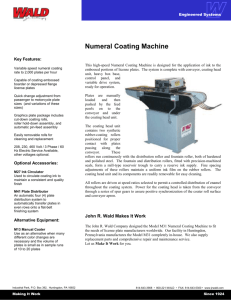

advertisement

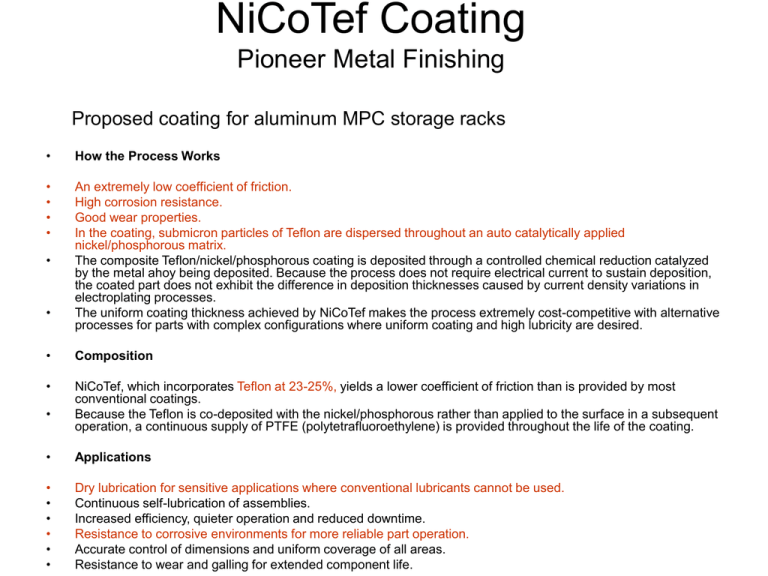

NiCoTef Coating Pioneer Metal Finishing Proposed coating for aluminum MPC storage racks • How the Process Works • • • • An extremely low coefficient of friction. High corrosion resistance. Good wear properties. In the coating, submicron particles of Teflon are dispersed throughout an auto catalytically applied nickel/phosphorous matrix. The composite Teflon/nickel/phosphorous coating is deposited through a controlled chemical reduction catalyzed by the metal ahoy being deposited. Because the process does not require electrical current to sustain deposition, the coated part does not exhibit the difference in deposition thicknesses caused by current density variations in electroplating processes. The uniform coating thickness achieved by NiCoTef makes the process extremely cost-competitive with alternative processes for parts with complex configurations where uniform coating and high lubricity are desired. • • • Composition • NiCoTef, which incorporates Teflon at 23-25%, yields a lower coefficient of friction than is provided by most conventional coatings. Because the Teflon is co-deposited with the nickel/phosphorous rather than applied to the surface in a subsequent operation, a continuous supply of PTFE (polytetrafluoroethylene) is provided throughout the life of the coating. • • Applications • • • • • • Dry lubrication for sensitive applications where conventional lubricants cannot be used. Continuous self-lubrication of assemblies. Increased efficiency, quieter operation and reduced downtime. Resistance to corrosive environments for more reliable part operation. Accurate control of dimensions and uniform coverage of all areas. Resistance to wear and galling for extended component life.