CONTENT - جامعة الملك عبدالعزيز

advertisement

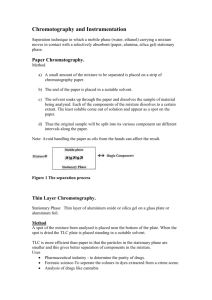

week Experiment Page no. 1 Extraction of Nickel as dimethyl glycoxime 1 2 a) Determination of Iron by chloride extraction 3 b) Separation of Iodine 5 3 Separation of mixture of K2Cr2O7 and KMnO4 by column chromatography 8 4 Paper chromatography 5 6 a) Separation of amino acids 10 b)Separation of metal ions from three groups 13 Paper chromatography a) Separation of halides 15 b) Separation of sugars 17 Thin layer chromatography a) preparation of Thin layer chromatography 20 b) Separation of chlorophyll 21 7 Separation of nitro phenol isomers by thin layer chromatography 23 8 a) Determination of an-ion-exchange resin 25 b) preparation of column 25 9 Determination of the total cation concentration in water 28 10 Gas – Liquid chromatography 30 Separation of a hydrocarbon mixture 11 Visit 12 Final Exam Experiment (1) Extraction of Nickel as the dimethy glyoxime complex Theory: Nickel (200-400 µg) forms the red dimethyglyoxime complex in a slightly alkaline medium; it is only slightly soluble in chloroform (35-50 µg Ni L-1). The optimum pH range for extraction of the nickel complex is 7-12 in the presence of citrate. The nickel complex absorbs at 366 nm and also at 465-470 nm. Chemicals: Amm. Nickel sulphate (0.135 g), citric acid (A.R.) 5 g, ammonia, dimethyglyoxime, chloroform and aluminium salt. Procedure: A homogenous solution of nickel (200-400 µg) and aluminium (500 µg) or iron (500 µg) is prepared. Transfer 10.0 ml of this solution (Ni content about 200 µg) to a beaker containing 90 ml of water, add 5.0 g of A.R. citric acid, and then dilute ammonia solution until the pH is 7.5. Cool and transfer to a separatory funnel, add 20 ml of dimethylglyoxime solution (1) and, after standing for a minute or two, 12 ml of chloroform. Shake for 1 minute, allow the phases to settle out, separate the red chloroform layer, and determine the absorbance at 366 nm in a l.0 cm absorbance cell against a blank. Extract with a further 12 ml of chloroform and measure the absorbance of the extract at 366 nm; very little nickel will be found. Test for the iron or aluminium in the aqueous layer. -1- Repeat the experiment in the presence of 500 µg of iron (III) and 500 µg of aluminium ion; on interference will be detected. Note: The dimethyglyoxime reagent is prepared by dissolving 0.50 g of A.R. dimethyglyoxime in 250 ml of ammonia solution and diluting to 300 ml with water. -2- Experiment (2) a) Determination of Iron by chloride extraction Theory: The extraction of iron(III) chloride from hydrochloric acid with diethyl ether (probably as the solvated complex H[FeCI 4] has long been known, but the amount of metal extracted depends upon the concentration of the acid and passes through a maximum at about 6M-hydrochloric acid. Elements that extract well as chloride complexes include Sb(V), As(III), Ga(III), Ge(IV), Tl(III), Hg(II), Mo(VI), Pt(II), and Au(III). Elements which are partially extracted include Sb(III), As(V), V(V), Co(II), Sn(II), and Sn(IV). Many solvents with donor oxygen atoms, including di-isopropyl ether, ββ′-dichlorodi ethyl ether, ethyl acetate, butyl acetate, and pentyl acetate, have been employed. In most cases the optimum extraction depends upon the acid concentration. The extraction of large amounts of iron is conveniently made with iso-butyl acetate: this solvent has the merit of low volatility and of almost negligible temperature rise during the extraction (unlike diethyl ether). . To gain experience in the procedure, experimental details are given for the extraction of iron (III) in hydrochloric acid solution with diethyl ether. -3- Procedure: Weigh out 16.486 g of A.R. hydrated ammonium iron (III) sulphate and dissolve it in 250 cm3 of 6M-hydrochloric acid in a graduated flask. Extract 5ml of the iron (III) solution (which contains 200mg of Fe) with three 5ml portions of pure diethyl ether (1): shake gently for 3 minutes during each extraction. Combine the three ether extracts and strip the iron from the ether by shaking with 25ml of water: approximately 99.9per cent of the iron is removed by this method. Boil off any ether remaining in the aqueous extract on a water- bath (caution!), and determine the iron by titration with standard 0.1N-potassium dichromate after previous reduction to the iron (II) state. The iron recovered should not be less than 99.6 per cent (2). Notes: The factors of importance in the diethyl ether extraction of iron are: a) The iron must be in the iron (III) state, since iron (III) chloride is not extracted. b) The hydrochloride acid concentration must be close to 6M. c) The extraction should be carried out in subdued light, since ether photochemically reduces iron (III). d) The ether should be free from ethanol and peroxides because these reduce iron (III) chloride. e) The concentration of anions other than chloride should be kept low. f)Heat is generated by the mixing of the ether and the hydrochloride acid iron (III) chloride solution so that cooling of the mixture under the tap or in ice is essential. -4- b) Separation of Iodine You will be given a homogenous mixture of iodine and sodium chloride in distilled water. . Theory: The iodine is separated by an extraction process. The aqueous iodine-salt solution, is shaken together with an approximately equal volume of carbon tetrachloride (CCL4). Water and carbon tetrachloride do not mix (they are insoluble in one another) hence two liquid phases will coexist here. Iodine vastly prefers to dissolve in CCL4, thus it migrates from the aqueous (H20) phase into the nonaqueous (CCI4) phase - we say that CC14 “extracts” the I2 from the aqueous phase. Cl has no such tendency (its solubility in CCL 4 is nil) and hence it remains behind in the water phase. Procedure: Pour all of filtrate into a clean 125 ml separatory funnel (suspended in an iron ring on a ring stand) whose stopcock is closed. Pour in 20 ml of carbon tetrachloride *, watch the added liquid to see whether it dissolves, floats as an upper layer, or settles as a lower layer. (Which liquid has the greated density CCI4 or H20?). Insert the separatory funnel stopper, and shake the closed funnel for about 10 sec. (Fig. 1). Shake vigorously enough so as to mix the aqueous and non-aqueous phases intimately. Keep your hand on the stopper, if internal pressure builds up, the stopper may pop out. To vent the inside pressure, hold the stoppered separatory funnel upside down, allow the liquids to drain away from the stopcock, and which the tip still pointing up, open the stopcock momentarily. Close the -5- stopcock, turn the separatory funnel upright, remove the top stopper, and allow the layers to separate as completely as possible. Carefully drain the lower layer through the stopcocker closing it just before the last drop of lower layer goes through. What will the lower layer be? Add another 20 ml portion of fresh CC1 4 to the remaining upper layer and repeat once more, drawing the second batch of CCL4 into a separate container. (Why must remove the top stopper from the separatory funnel each time before attempting to drain out the lower layer?). Repeat a third time. Separately save the second and third portions of CCl 4, note and compare their color with the first portion. Show these carbon tetrachloride solutions, to your laboratory instructor. Save the aqueous layer. -6- Iodine test*: In the presence of iodine, the white color of the starch paper changes to deep blue. Dip your stirring rod into the solution and then touch it to a piece of the starch paper. Be sure your stirring rod is thoroughly rinsed before and after each use. Chloride test: To a test tube containing the sample (the aqueous layer), add 2 drops of nitric acid (HN03, 6M HN03) and then 1 drop of silver nitrate solution (0.05 M AgNO3). You will observe a precipitate. Exercise: Suggest a volumetric method for the determination of iodine and chloride after the separation. Discuss the theory of the indicator used in each method. * Iodine and its vapours are very corrosive and toxic. Do not allow it to touch your skin or clothing, avoid inhalation. -7- Experiment (3) Separation of mixture of potassium permanganate and potassium dichromate by column chromatography Theory: The separation of mixture containing both the potassium dichromate and potassium permanganate pass from the separation column containing material alumina acid, solvent using distilled water as the loyal and adsorption dichromate on the surface of alumina acid more adsorption permanganate therefore concludes permanganate first. If checked consider dichromate layer orange in the separation column you will notice a yellow minutes of chromate potassium accompanying the potassium dichromate and who is with him in equilibrium as shown in the following equation: Cr2O 72 + H2O ↔ 2HCrO 4 Chemicals: 1- 16-18 gm of alumina acid. 2- 1% of potassium dichromate solution. 3- 1% of potassium permanganate solution. 4- Commingle sizes equal from both potassium dichromate and potassium permanganate. 5- 1mol/L sulfuric acid. 6- 1mol/L nitric acid. -8- Procedure: 1- Prepare the separation column from alumina acid the length of column 12-15 cm. 2- Open the tap separation column and waited until the water level slightly above the surface of alumina. 3- Convey very carefully 5ml of the mixture to be separated by pipette in one go to the highest separation column. 4- Put 100ml of distilled water in the separating funnel installed over the brink separation column and leave the water is equal to a fixed rate of 5ml per minute. 5- Process repeated washing with water several times until the violet permanganate layer separating from layer dichromate yellow. 6- Extract the isolated permanganate on the column by washing the column by 50ml nitric acid solution, which concentration 1 mol / liter by the rate of about 2 ml per minute and collect the effluent in conical flask. 7- Extract the isolated potassium dichromate on the column by washing the column by 50ml sulfuric acid solution, which concentration 1 mol / liter and collect the effluent in conical flask. 8- For quantitative analysis both permanganate and dichromate used spectral methods or by volumetric analysis. -9- Experiment (4) Separation of amino acid by paper chromatography Theory: Paper chromatography is a techniques used to separate complex mixtures of drugs, metal ions, amino acids and dyes. One of the classic applications of paper chromatography is the separation of amino acids. The sample is spotted on the paper, eluted and subsequently visualised by reaction with ninhydrin to form a purple or brown colour. Qualitative identification is made by calculation of Rf values for each spot. Rf = distance solute moved / distance solvent moved. Quantitative determination can be made by comparison of the intensity of the colour with standards. Chemicals: 1- Reagents:L-leucine, DL-aspartic acid, L-lysine and mixture of the three amino acids. Use 1% aqueous solution. 2- Solvent: n-butanol: acetic acid gloicol: water 60 : 15 : 25 by volume. 3- Sheets: Whatman chromatographic paper. 4- Equipments: Chromatography tank, capillaries, hair dryer, spray bottle. 5- Locating reagent: Ninhydrin (0:2 gm in 100 ml acetone). - 10 - Procedure: 1- Place sufficient solvent into the bottom of the tank cover the lid and allow the tank to be saturated with the solvent. 2- Take a sheet of Whatman chromatography paper (about 10-30 cm) and place it on a piece of clean paper on a bench. 3- Draw a fine line with a pencil along the width of the paper and about 1.5 cm from the lower edge. 4- Along this line place four equally spaced (about 2 cm apart) small circles with a lead pencil. 5- Label the paper at the top with the name of each of the three amino acids and label the fourth unknown. 6- Use a fine capillary or tooth pick to place drops of the solutions to be chromatographed and dry each drop before applying the next drop. 7- After spotting, allow the paper to air dry for 5 minutes then use a hot-air hair dryer for one minute. 8- Place the spotted paper in the chromatographic tank and make the development using the ascending technique. 9- Close the tank with lid, allow solvent to flow for about 1.5 hou. 10- Remove the paper and immediately mark the position of the solvent front with a lead pencil. 11- After the chromatogram has dried: spray the paper with 0.2 ninhydrin solution. 12- Put the sprayed paper in an oven at 105° C for two minutes. The amino acids will form purple or blue spots. The colour is stable for some weeks if kept in the dark away from acid vapours. - 11 - 13- For permanent record, circle the position of each spot with a pencil. 14- Compute the Rf values and record them in a table for both for single amino acids and for the components of the mixture (compare). - 12 - b) Chromatography, ascending or descendingseparation of metal ions from three groups (Co2+, Ni2+, Cu2+, Fe3+) Theory: The separation and identification of metal cations from different groups by paper chromatography. Chemicals: 1- Reagents: A solution containing 20 mg/mI of chlorides of each of: (Co2+, Ni2+, Cu2+, Fe3+). 2- Solvent: Acetone: conc. HCL: water 86 : 6 : 8 by volume. 3- Sheets: Whatman chromatographic paper. 4- Equipments: Chromatography tank, capillaries, hair dryer, spray bottle. 5- Locating reagent: Ammonia. Procedure: 1) Place 50 ml of solvent in the bottom of the tank. cover the lid. 2) Prepare the paper, and place three spots of the mixture, evenly spaced, along the base line. . 3) Form the paper into a cylinder and secure with the tongued clips, Part G. Place the cylinder, with the spotted end down, in the tank taking care not to let the paper touch the glass walls. 4) Close the tank with the lid. - 13 - 5) If the chromatogram is observed closely, a yellow band due to Cu may be seen moving behind the solvent front. The locating reagents are prepared as above. 6) After the solvent front has travelled about 1/2 of the length of the paper, remove the chromatogram from the tank, mark the solvent front with a pencil, open out and dry. 7) After the chromatogram has dried: spray the paper with ammonia solution. This shows Nickel is blue spot, Cobalt is yellow brown spot, Copper is olive green spot, and Iron is reddish brown. 8) Compute the Rf values. - 14 - Experiment (5) a) Chromatography, ascending the separation of anions the halides CI, Br, I Theory: Separation of anions (the halides), and their locating on paper chromatograms. Chemicals: 1- Reagents: (a) Potassium chloride/water - 10 mg/ml. (b) Potassium bromide/water - 10 mg/ml. (c) Potassium iodide/water - 10 mg/ml. (d) A solution of the above salts in the same concentrations. (e) A solution of any two to of above salts as an unknown. 2- Solvent: iso-propanol: acetone: 0.880 ammonia solution. 40 : 30 : 30 by volume. 3- Sheets: Whatman chromatographic paper. 4- Equipments: Chromatography tank, capillaries, hair dryer, spray bottle. 5- Locating reagent: 0.1 m/L Silver nitrate. Procedure: 1) Place 50 ml solvent in bottom of the tank. Replace the lid. 2) Use a fine capillary or tooth pick to place drops of the solutions to be chromatographed and dry each drop before applying the next drop. 3) After spotting, allow the paper to air dry for 5 minutes then use a hot-air hair dryer for one minute. - 15 - 4) Place the spotted paper in the chromatographic tank and make the development using the ascending technique. 5) Close the tank with lid. 6) Remove the paper and immediately mark the position of the solvent front with a lead pencil. 7) After the chromatogram has dried: spray the paper with Silver nitrate solution. This shows Chloride is gray spots, Bromide is yellowish gray spots, and Iodide is yellow spots. 8) For permanent record, circle the position of each spot with a pencil. 9) Compute and compare the Rf values of each anion, when run individually and when run in a mixture with the others. - 16 - b) Chromatography, ascending or descending the separation of sugars Theory: a) The separation and identification of individual sugars and mixtures of naturally occurring sugars by paper chromatography. b) Determination of Rg values. Chemicals: 1- Reagents: D (+) – glucose. D (+) – xylose. Lactose. Fruit juices. 2- Solvent: ethyl acetate: pyridine: water. 55 : 25 : 20 by volume. 3- Locating reagent: m- phenylene diamine - 0.5 g. Stannous chloride - 1.2g. acetic acid - 20 ml. Ethanol - 80 ml. Procedure: 1) Place 50 ml of solvent in the tank, replace the lid. 2) Prepare 25 x 25 cm paper with eight origins and number one through eight. 3) Onto origins 1, 2 and 8, spot one drop of lactose solution. 4) Allow the spot to dry spontaneously, or by blowing over them a current of air from a hair dryer. 5) Spot a dry of glucose solution on to origins 1, 3 and 8. 6) Dry again. - 17 - 7) Spot a drop of xylose solution on to origins 1, 4 and 8. 8) On to origins 5, 6 and 7, spot a drop of different fruit juices. 9) From the paper into a cylinder and secure with the tongued clips, part G. Place the cylinder, with the origins end down, into the tank taking care not to let the paper touch the glass walls. Close the tank with the lid. 10) No observation can be made while the chromatogram is running because the sugars are colorless. 11) Allow the chromatogram to run until the solvent front reaches nearly to the top of the paper or, preferably, overnight. 12) Remove the chromatogram from, the tank, mark the solvent front with a pencil, open out and dry (see Note). 13) Pour the locating reagent into the drip tray, and dip the chromatogram. 14) Heat the dipped paper for up to 5 minutes in an oven at 100-105 C. The sugars from dark yellow to brown spots. 15) Compare and compute the Rg values of each sugar when run individually and when run in a mixture with the others. Conclusions: (i) Colourless sugars can be separated and identified by paper chromatography through the use of a locating reagent which transforms them into coloured spots on the paper. (ii) The Rg values of sugars are the same whether run individually or in mixtures with each other. . (iii) Chromatography is a useful technique for the analysis of sugar mixtures. . - 18 - Note: If the chromatogram is allowed to run overnight, the solvent front reaches the to evaporate top of the paper and continues to evaporate off the edge. In this case, no true front is available for the computation of Rf values. In such chromatograms, it is the practice to use an Rg value, based on the distance traveled by the glucose as the preference point, and computed by the following formula: Rg= distance the substance has run from the origin x 100 distance the glucose has run from the origin Thus, the Rg for glucose itself is 100. - 19 - Experiment (6) Thin layer chromatography (TLC) When a separation of components in a mixture is attempted, TLC has several advantages over paper chromatography: 1. The time taken to achieve separations is far less than that for paper chromatography. 2. The resolution of components is usually superior. 3. It is possible to apply to coated plates a variety of corrosive location reagents that would destroy paper chromatogram. 4. The non-fluorescing inorganic adsorbents used in TLC provide a greater contrast to fluorescent spot than does chromatographic paper. 5. The wide range of adsorbents available enhances the flexibility of the method. a) Preparation of the plates: 1- Plates themselves should be cleaned with detergent solution, then rinsed thoroughly with water and allow to dry. 2- Silica gel G is slurried with disi1led water. Generally, two parts of water are mixed thoroughly with one part of adsorbent. 3- The slurry is then applied to the plates in a thickness of 0.25 mm. - 20 - 4- The plates are left in the air for 2 hours and then dried in an oven at 105 - 110°C for one hour and stored in a disicator. b) Separation of chlorophyll and related compounds by TLC Theory: The depend method of separating the components of green plants on the adsorption difference of green material on the surface of silica gel existing in the form of thin layer. This method is similar to the method largely separation chromatography by column. Chemicals: Fresh leaves, sand, chloroform, mortar and TLC silica gel plate. Solvent: isopropyl alcohol: petroleum ether: acetone. 10 : 50 : 50 by volume. Procedure: 1) Place 50 ml of solvent in the tank, replace the lid. 2) Prepare the thin layer plate (Silica gel are mixed with distilled water). 3) Obtain a small quantity of green plant material and grind it in a morter with some sand. 4) Extract the mashed plant material with 5ml of acetone or chloroform then filter the liquid, which should be coloured deep green. 5) The solutions of chlorophyll are spotted on the same plate about 2 cm apart using a capillary tube. Spotting is carried out following the same technique used in paper chromatography. - 21 - 6) The plates are placed in tightly covered tank containing the mobile phase. When the solvent moves about 12 cm the plates are removed and air-dried. 7) Describe the colour separations which you observed (The green substance is chlorophyll. The orange band is due to a closely related group of compounds called carotenes. The yellow band is produced by xanthophylls). 8) Calculate the Rf values. - 22 - Experiment (7) Separation of nitro phenol isomers by thin layer chromatography Theory: Chromatography is thin layer of an important way to separate images isomers of organic compounds from each other. The experience separation of a mixture composed of ortho and meta and para nitrophenol (o-nitrophenol, m-nitrophenol and p- nitrophenol) good example of the use of thin layer Chromatography. Chemicals: 1- Prepare the 0.1% from an aqueous solution of each of the three images nitrophenol isomers. 2- A mixture of unknown contains two from phenols the previously mentioned. 3- Solvent: methanol: benzene. 5 : 95 by volume. 4- Locating reagent: 1% alc. KOH. Procedure: 1) Prepare the thin layer plate is used the silica gel as constant medium. 2) Place of solvent (stationary phase) in the tank. 3) Cover the lid and allow the tank to be saturated with the solvent. 4) Draw a fine line with a pencil along the width of the thin layer plate and about 2 cm from the lower edge. - 23 - 5) Use a fine capillary to place drops of the solutions to be chromatographed and dry each drop before applying the next drop. 6) Place the spotted plate in the chromatographic tank and make the development using the ascending technique. 7) Close the tank with lid, allow solvent to flow. Remove the paper and immediately mark the position of the solvent front with a lead pencil. 8) After the chromatogram has dried: spray the plate with 1% alcohol KOH. 9) Describe the colour separations which you observed (the yellowish orange spot is o-nitrophenol. The yellow spots are produced by m-nitrophenol and p-nitrophenol). 10) Calculate the Rf values. - 24 - . Experiment (8) Determination of the capacity of an ion-exchange resin Theory: The total ion-exchange capacity of a resin is dependent upon the total number of ion-active groups per unit weight of material, and the greater the number of ions the greater will be the capacity. The total ion-exchange capacity is usually expressed in milli equivalent / gm of exchanger. The exchange capacity of a cation-exchange resin may be measured in the laboratory by determining the number of milligram equivalents of sodium ion which are absorbed by 1 gm of the dry resin in the hydrogen form. Similarly, the exchange capacity of a strongly basic anion exchanger is evaluated by measuring the amount of chloride ion taken by 1 gm of the dry resin in the hydroxide form. Determination of the capacity of anion-exchange resin: Chemicals: 1- Air dried strongly basic anion exchanger (Dowex 20-50 chloride form). 2- Sodium nitrate solution Ca. 0.25 M. Procedure: 1- Dry off purified resin by placing it in an evaporating dish (over with a watch glass supported on two glass rods to provide protection from dust while giving access to the air. 2- Leave in warm place (25-35°C) until the resin is completely freerunning (2-3 days). - 25 - 3- Partly fill a small burette, provided with a glass wool plug at the lower end, with distilled water taking care to displace any trapped air from beneath the glass wool plug. 4- Weigh out accurately about 0.5 gm of the air-dried resin in a weighing bottle. 5- Transfer the resin with the aid of a small camel hair brush through a dry funnel into the column. 6- Add sufficient distilled water to cover the resin. 7- Adjust the level of the out let tube so that the liquid in the column will drain to a level about 1 cm above the resin beads. 8- Fill a 250 ml separating funnel with Ca 0.25 M NaNO 3 and allow this solution to drop into the column at the rate of about 2 ml / minute. Collect the effluent in a 500 ml conical flask, and titrate with standard 0.1 N AgNO3 using potassium chromate as indicator (Mohr method). The reaction which occurs may be written as: R+C1- + NaNO3 R+NO 3 + NaC1 Calculation: The capacity of the resin expressed as meq / gm is given by: N x V / W (where: N is the normality of AgNO3, V is the volume of AgNO3 and W is the weight of the resin. - 26 - Standardisation of AgNO3 solution: 1- Pipette 25 ml of standard 0.1 N NaC1 into a 250 ml conical flask. 2- Add 1 ml of indicator solution K2CrO4. 3- Add AgNO3 solution from a burette, swirling the liquid constantly, until the red colour formed by the addition of each drop begins to disappear more slowly (match the colour against a white filter paper), this is an indication that most of the chloride has been precipitated. 4- Continue the addition drop by drop until a faint but distinct change in colour occurs. The faint reddish- brown colour should persist after brisk shaking. 5- Calculate the normality of AgNO3 solution from the relation: N x V = N′ x V′ - 27 - Experiment (9) Determination of the total cation concentration in water Theory: The following procedure is a rapid one for the determination of the total cations present in water particularly that used for industrial ion exchange plant but may be used for all samples of water, including tap water. When water containing dissolved ionised solids is passed through a cation exchanger in the hydrogen form, all cations are removed and replaced by hydrogen ions. By this means, any alkalinity present in the water is destroyed and the neutral salts present in solution are converted into the corresponding mineral acids. The effluent is titrated with 0.02M sodium hydroxide using screened methyl orange as indicator. Chemicals: Amberlite resin, 0.1M NaOH, methyl orange indicator and tap water. Procedure: 1) Prepare column of Amberlite resin (H-form). The level of the water should never be permitted to drop below the upper surface of the resin in the column. 2) Pass 150 ml of the sample of water under test through the column at a rate of 3-4 ml per minute, and discard the effluent. 3) Now pass two 120 ml portions through the column at the same rate. - 28 - 4) Collect the effluents separately, and titrate each with standard 0.1M NaOH using screened methyl orange as indicator. From the results of the titration, calculate the milli-equivalents of calcium present in the water. It may be expressed, if desired, as the equivalent (E.M.A.) in terms of mg CaCO3 per L of water (i.e., parts per million of CaCO3). In general, if the titre is A ml of NaOH of molarity B for an aliquot volume of V ml, the E.M.A. is given by (AB × 50 × 1000) / V. Commercial samples of water are frequently alkaline due to the presence of hydrogen carbonates, carbonates, or hydroxides. The alkalinity is determined by titrating a 100 ml sample with 0.02 M hydrochloric acid using screened methyl orange as indicator (or to a pH of 3.8). To obtain the total cation content in terms of CaCO3, the total methyl orange alkalinity is added to the E.M.A. Results: (NV)NaOH = (NV)H+ = (NV)CaCO3 = (wt/eq.wt x 1000) CaCO3 Total hardaness ppm CaCO3 = wt x 106 / 150 - 29 - Experiment (10) Gas - Liquid Chromatography Separation of a hydrocarbon mixture Gas chromatography is probably the most valuable separation technique developed to date. A small amount of the liquid sample is injected into a hot injection chamber where it is changed into a gas. The gas is partitioned between the inert, carrier gas (usually helium) and a nonvolatile, high molecular weight, organic stationary phase that is coated on a solid support. Because of their differences in solubility in the stationary phase, the sample components are separated. Apparatus: Gas chromatography with a nonpolar column, in this experiment, the effects of column temperature on the separation of series of hydrocarbons will be investigated. Also the determination of each hydrocarbon in the sample will be carried out. Procedure: 1- Prepare a mixture of propanol, heptane and octane in different proportion. Using an appropriate column set the following parameters on the gas chromatograph: a- Column temperature 60°C. b- Injection chamber temperature at least 135°C. c- Detector temperature at least 150°C. d- Gas flow rate, 30 cm3/min. e- Filament current to 150 m A (in case of TCI) detection. - 30 - f- Record the length of the column. 2- After the instrument has come to equilibrium inject 2 µl of the mixed hydrocarbon sample and allow the three components to elute. 3- Carry out the experiment with column temperature at 110, 100, 75, 65 and 60°C while keeping the flow rate constant at 30 cm3/min. 4- Determine which temperature is optimum, and adjust the column to that temperature. 5- Successively inject and record the chromatogram of 3 µl portions of the sample until the height of the first peak is identical for three injections. 6- Successively inject and record the chromatograms of 0.5, 1.0, 1.5, 2.0 and 2.5 µl portions of pure propanol, heptane and octane. Calculations: 1- Use the chromatograms of the sample to calculate the adjusted retention time (tR) for each of the three sample component peaks. Qualitatively determine the sample component that is responsible for each of the three sample peaks by comparing the retention times of the sample peaks with those of the pure hydrocarbons. 2- Calculate the resolution of the column. Rs = t R 2 t R1 1 / 2( w1 w2 ) The resolution is complete if Rs > 1 .5. 3- Calculate the number of theoretical plates N = 16 (t R /w) 2 and the height equivalent of a theoretical plate H.E.T.P = L / N for each of the three sample components in one of the sample chromatogram. 4- Prepare a working curve for each of the pure hydrocarbon by plotting peak height against the injected volume of the hydrocarbon. - 31 - 5- Use e three working curves to determine the volume of each hydrocarbon in the sample. 6- Use the volumes of each component in the sample to determine percentage of each (v/v %) in the sample. Percentage = Volume of component Volume of sample injected - 32 - X 100 References: 1- J. Bassett et.al., Vogel’s textbook of quantitative inorganic analysis, fourth edition, , Longman, (1978). -2الكيمياء التحليلية تجارب عملية في طرق التحليل اآللي ،تأليف :أ.د .عبد الغني حمزة وآخرون ،مركز النشر العلمي جامعة الملك عبد العزيز-جدة ،الطبعة الثالثة -1424 .2003 -3أسس الكيمياء التحليلية ،تأليف :د .مويد قاسم العباحى ،د .ثابت سعيد الغبشة ،وزارة التعليم العالي والبحث العلمي -جامعة الموصل. 4- http:// www.juliantrubin.com. - 33 -