course outline - Modesto Junior College

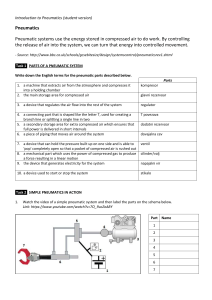

advertisement

AA/AS Degree X Date Originally Submitted: MODESTO JUNIOR COLLEGE Non-Degree Date Updated: COURSE OUTLINE 11/7/2000 Noncredit I. DIVISION: Agriculture & Environmental Sciences PREFIX/NO.: AG-M 262 Formerly listed as: Hours/Week: DIV./DEPT. NO: 11/2500 COURSE TITLE: Hydraulics/Pneumatics AG-M 362 Date Changed: Lecture: 3 Lab: Other: % Load: .15 % Load: % Load: If catalog is to read lecture/lab check here Other (explain): II. ALSO OFFERED AS: Div: III. Technical Education Div: COURSE INFORMATION: No. Weeks: Offered Only: TOP: 3 SAM: .15 CAN: IV. Spring INTEC 262 Title: Hydraulics/Pneumatics Prefix/No.: 18 Units: Tot % Load: Prefix/No.: Title: 0116.00 State Class: C I Method of Instruction: Wk/Ex: 10 In-Service: Apprentice: Summer Fall Eve Not offered every semester: PREREQUISITE(S)/COREQUISITE(S)/RECOMMENDED FOR SUCCESS: Prerequisite (P) Corequisite: (C) Recommended for success (R) (Please check all that apply and list below. Also attach appropriate documentation forms) V. CATALOG DESCRIPTION: Principles and practices of hydraulics/pneumatics as used in the industry. Study of the different applications and management of hydraulics for the most efficient use. Basic pneumatic principles and application systems. VI. FIELD TRIPS REQUIRED? VII. GRADING: VIII. REPEAT PROCEDURES: Yes A-F Only No CR/NC Only Credit: No Non-Credit: No * IX. EXPLAIN FEE REQUIRED: Rev: 8/98 None. X Maybe X CR/NC Option X Yes X Maximum Completions: Yes Maximum Completions: Non-Grades 2 Maximum Units: 6* 2 AG-M 262 Hydraulics/Pneumatics X. PREREQUISITE SKILLS Before entering the course, the student will be able to: XI. OBJECTIVES (Expected outcomes for students) Upon successful completion of the course, the student will be able to: A. Identify the components which make up common industry hydraulic and pneumatic systems. B. Explain common terms and identify problems related to pneumatics and hydraulics. C. Apply basic hydraulic and pneumatic design concepts to stationary and mobile equipment. D. Outline common fluid system service procedures. E. Analyze and test fluid systems for failures. F. Develop good service procedures to prolong system life. G. Demonstrate pneumatic tool use and care. H. Match fluids to appropriate hydraulic systems. I. Examine each of the five main system components. J. Test for and diagnose common hydraulic system and preventive system problems. K. Outline the development history, technical applications, and limitations of hydraulic and pneumatic systems. XII. CONTENT A. History of fluid use and development 1. Hydraulics in industry 2. Pneumatics in industry 3. Use of power in agriculture and industrial applications 4. The place of fluid power/energy relationship in equipment design B. Uses and application of hydraulics and pneumatics in industry 1. Systems 2. Applications 3. Basic physical science and mechanical laws governing hydraulics C. Components of hydraulics and their management Rev: 8/98 1. Pumps 2. Valves—flow control components 3. Cylinders and other activators 4. Seals and packing 3 AG-M 262 Hydraulics/Pneumatics 5. Lines and fittings 6. Other system components 7. Pneumatic system components and differences D. Transmissions—hydrostatic 1. Types 2. Application in power equipment E. Fluid properties F. XIII. Function and characteristics 2. Fluid passages and transmission lines 3. Pressure drops Maintenance of hydraulic and pneumatic systems 1. Servicing and adjusting 2. Inspecting and testing 3. Repairing and overhauling TEACHING METHODS A. B. XIV. 1. Methods to achieve course objectives: 1. Related material will be presented through designated class lecture and lab demonstrations. 2. Additional studies will be required from technical manuals specific to individual topics. 3. Students to augment classroom lecture will complete problem-solving situations. Methods used in achieving learner independence and critical thinking: 1. Each student is required to provide a written assessment of the demonstrated lab project and must specify the results obtained. 2. Given a problematic task, each student is required to delineate the steps needed to resolve the problem or obtain the prescribed results. 3. The student will diagram basic pneumatic/hydraulic systems showing the essential components. TEXTBOOKS (Typical) FOS Hydraulics, Deere, Deere & Co. Publishing 4 AG-M 262 Hydraulics/Pneumatics XV. SPECIAL STUDENT MATERIALS (i.e., protective eyewear, aprons, etc.) None XVI. METHODS OF EVALUATING STUDENT PROGRESS A. Descriptive project analysis B. Individual examination C. Discussion and group presentations D. Problem-solving exercises