Gas Power Cycles

advertisement

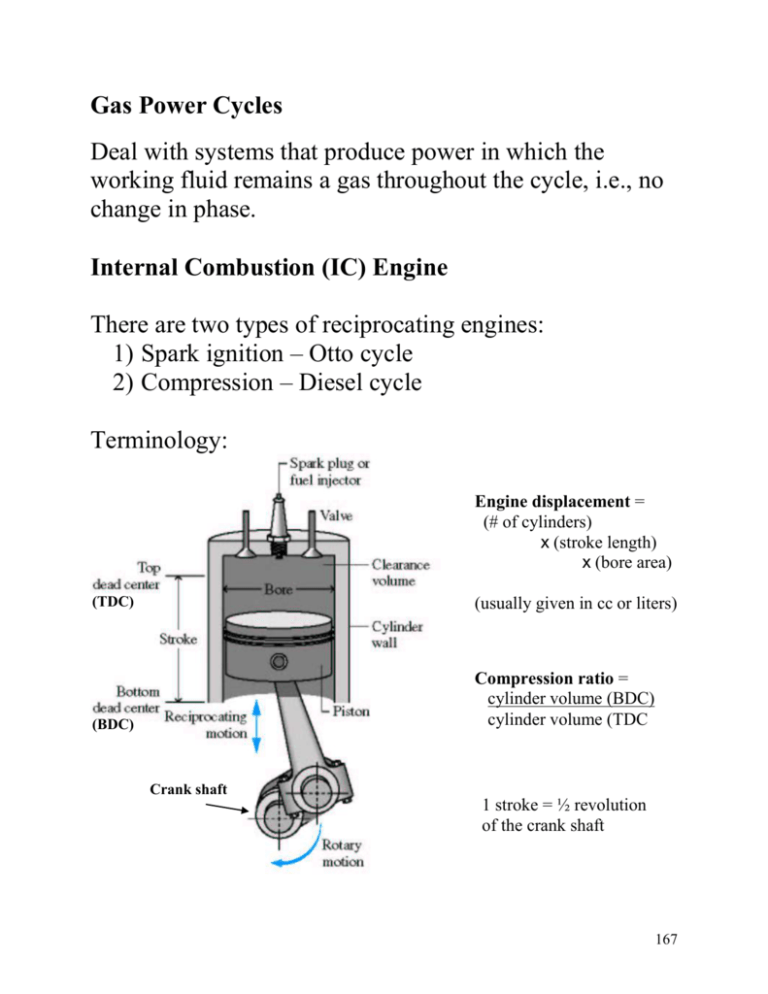

Gas Power Cycles Deal with systems that produce power in which the working fluid remains a gas throughout the cycle, i.e., no change in phase. Internal Combustion (IC) Engine There are two types of reciprocating engines: 1) Spark ignition – Otto cycle 2) Compression – Diesel cycle Terminology: Engine displacement = (# of cylinders) x (stroke length) x (bore area) (TDC) (usually given in cc or liters) (BDC) Compression ratio = cylinder volume (BDC) cylinder volume (TDC Crank shaft 1 stroke = ½ revolution of the crank shaft 167 Four stroke Spark Ignition Engine: Cycle consists of four distinct strokes (processes) A FUEL Intake I valve R opens Ignition Fuel/Air Mixture Intake Stroke Compression Stroke Exhaust valve opens Combustion Products Power Stroke Exhaust Stroke A complete cycle (4 strokes) requires two revolutions of the crank shaft x Ignition 1 atm 168 A comprehensive study of IC engines requires consideration of the details of the air intake, combustion, and exhaust processes (MECH 435 – 4th year elective) Thermodynamic Air-Standard Analysis Used to perform elementary analyses of IC engines. Simplifications to the real cycle include: 1) Fixed amount of air (ideal gas) for working fluid 2) Combustion process replaced by constant volume heat addition with piston at TDC 3) Intake and exhaust not considered, cycle completed with constant volume heat removal with piston at BDC 4) All processes considered internally reversible Air-Standard Otto cycle Process 1 2 Isentropic compression Process 2 3 Constant volume heat addition Process 3 4 Isentropic expansion Process 4 1 Constant volume heat removal 169 Qin AIR Qout AIR AIR TDC AIR BDC (1) (2) (2) (3) (3) (4) (4) (1) Qin Qout v2 v1 TDC BDC TDC compression ratio r V1 V4 V2 V3 since fixed mass r v1 v4 v2 v3 BDC 170 Apply First Law ( u Q W ) to each process: m m 12 Isentropic Compression (u 2 u1 ) W Q ( in ) m m AIR Win (u 2 u1 ) m vr2 vr1 v2 1 v1 r R P2 v2 P1v1 P T v 2 2 1 T2 T1 P1 T1 v2 23 Constant Volume Heat Addition (u3 u 2 ) ( Qin W ) m m AIR Qin Qin (u3 u 2 ) m v P P T P2 3 3 3 RT2 RT3 P2 T2 171 3 4 Isentropic Expansion (u 4 u3 ) W Q ( out ) m m AIR Wout (u3 u 4 ) m vr4 v4 r vr3 v3 P4 v4 P3v3 P T v 4 4 3 T4 T3 P3 T3 v4 4 1 Constant Volume Heat Removal (u1 u 4 ) ( Qout W ) m m AIR Qout Qout (u 4 u1 ) m P4 P1 P4 P1 v RT4 RT1 T4 T1 172 Otto cycle thermal efficiency is cycle Wcycle m Qin m otto Wout m Win m u3 u 4 u 2 u1 u3 u2 Qin m u3 u2 u4 u1 u3 u 2 cycle u 4 u1 1 u3 u 2 Cold Air-Standard Analysis The specific heats are assumed to be constant at their ambient temperature values. For the two isentropic processes in the cycle, assuming constant specific heat yields: 12: 34: T2 v1 T1 v2 k 1 T4 v3 T3 v4 k 1 r k 1 1 r and k 1 and k 1 k T2 P2 T1 P1 k 1 k T4 P4 T3 P3 where k= 1.4 for air at ambient temperature. 173 Furthermore, for constant specific heats u cV T so otto cycle but T1 T4 1 T1 c T T u u 1 4 1 1 V 4 1 1 T u3 u 2 cV T3 T2 T2 3 1 T2 r k 1 T T2 T3 T 4 3 T1 T4 T1 T2 otto const cV 1 so T1 1 1 k 1 T2 r For high thermal efficiency want a high compression ratio Current spark ICE 7 < r < 10 174 Spark ignition engine compression ratio limited due to a phenomenon known as “knock” Knock refers to the noise produced when combustion occurs explosively damaging to engine. In order to reduce knock between 1920 and 1975 tetraethyl lead added to gasoline r = 12 possible Also, larger r higher T2 higher T3 more emissions such as NOx and Sox 175 Engine Power W (“horse power”) work work cycles work cycles crank revs time cycle sec cycle crank revs sec For a 4 stroke engine, 2 crank shaft revs per cycle N W Wcycle 2 where N crank shaft speed (rev/s) Increase power by increasing the engine speed N Another way to increase power is to increase the net work output per cycle Wcycle by either: (i) Increasing the compression ratio, or (ii) Increase Qin (increase the engine displacement). P 3 (ii) Qin Wcycle 4 2 (i) 1 V2 V1 V 176 Another Parameter used to indicate engine performance is the mean effective pressure (mep) – the theoretical constant pressure that, if it acted on the piston during the power stroke, would produce the same net work as actually developed in one cycle, i.e., Wcycle net work per cycle mep displacement volume V1 V2 For two engines with same displacement volume, the one with a higher mep produces more net work, and at the same engine speed would produce more power. 177 Four stroke Compression Engine No spark plug for ignition, rely on autoignition at high temperature for initiating combustion A I R Intake valve opens Fuel Injector Combustion Products Air Intake Stroke Compression Stroke Exhaust valve opens Power Stroke Exhaust Stroke When piston approaches TDC when air is near its maximum temperature fuel injection is started combustion initiated. Continue to inject fuel as the piston is moving down (mixture volume is increasing) at the same time liquid fuel evaporates and reacts as it passes through the standing flame combustion occurs at roughly constant pressure 178 Air-Standard Diesel cycle Process 1 2 Isentropic compression Process 2 3 Constant pressure heat addition Process 3 4 Isentropic expansion Process 4 1 Constant volume heat removal Qin AIR Qout AIR AIR TDC AIR BDC (1) (2) (2) (3) (3) (4) (4) (1) Qin Qout v2 v1 TDC BDC 179 Recall compression ratio r v1 v2 Define the cut-off ratio rc V3 v3 V2 v2 Apply First Law ( u Q W ) to each process: m m 12 Isentropic Compression (u 2 u1 ) W Q ( in ) m m AIR Win (u 2 u1 ) m vr2 v2 1 vr1 v1 r P2 v2 P1v1 P2 T2 v1 R T2 T1 P1 T1 v2 180 23 Constant Pressure Heat Addition Qin P2 V3 V2 (u3 u 2 ) ( ) m m AIR Qin Qin (u3 P3v3 ) (u 2 P2 v2 ) m Qin ( h3 h2 ) m T v RT2 RT3 3 3 rc v2 v3 T2 v2 P 3 4 Isentropic Expansion (u 4 u3 ) W Q ( out ) m m AIR Wout (u3 u 4 ) m vr4 vr3 vr4 vr3 v4 v3 v4 r v3 rc note v4=v1 and v4 v4 v2 v1 v2 r v3 v2 v3 v2 v3 rc P4 v4 P3v3 P T r 4 4 T4 T3 P3 T3 rc 181 4 1 Constant Volume Heat Removal (u1 u 4 ) ( Qout W ) m m AIR Qout Qout (u 4 u1 ) m P4 P1 P4 P1 v RT4 RT1 T4 T1 Diesel cycle thermal efficiency is cycle Wout m Win m Qin m Qout m m Qin m Qin m Wcycle m Qin Diesel 1 cycle Qout m u u 1 4 1 Qin m h3 h2 182 Cold Air-Standard Analysis The specific heats are assumed to be constant at their ambient temperature values. For the two isentropic processes in the cycle, assuming constant specific heat yields: T2 v1 12: T1 v2 k 1 T4 v3 T3 v4 k 1 34: r k 1 r c r and k 1 and k 1 k T2 P2 T1 P1 k 1 k T4 P4 T3 P3 where k= 1.4 for air at ambient temperature. For constant specific heats u cV T and h c P T so Diesel cycle T1 T4 1 T1 c T T u u 1 1 4 1 1 V 4 1 1 h3 h2 c P T3 T2 k T T3 1 2 T2 183 recall: T1 1 k 1 T2 r T4 rc T3 r T3 rc T2 T4 T4 T3 T2 rc T1 T3 T2 T1 r k 1 k 1 rc r k 1 rck substituting yields Diesel const cV 1 1 rck 1 1 k 1 r k rc 1 For given rc higher thermal efficiency is obtained via higher compression ratio r For a given r higher thermal efficiency is obtained via lower cut-off ratio rc However a smaller rc yields less net work per cycle, so to achieve the same power need higher engine speeds 184 Compare Efficiency of Otto and Diesel Cycles Otto const k 1 1 r k 1 Diesel const k 1 1 rck 1 1 k 1 r k rc 1 Current Diesel ICE 12 < r < 23 Note: for a given compression ratio the diesel engine is less efficient than the spark ignition engine Otto const cV 1 1 r k 1 Diesel 1 const cV 1 r k 1 1 185 Compare the Otto cycle (1-2-3O-4O) and the Diesel cycle (1-2-3D-4D) for: - the same compression ratio, v1 v2 Otto v1 v2 Diesel - the same heat input, 23D Tds 23O Tds (same area under the curve 2-3 for both cycles) 3O P= const V= const 3D 2 4D 4O V= const 1 186 The heat rejected by the Otto cycle Qout is less than that for the Diesel cycle: 4O Tds 4 D Tds 1 1 Since Wcycle = Qin – Qout the net cycle work for the Otto cycle is greater than that for the Diesel since Qout is smaller for the Otto cycle Since cycle Wcycle Qin Otto Diesel cycle cycle However, since one can use a higher compression ratio for the Diesel one can achieve obtain a higher cycle efficiency! 187