ABSTRACT: This document provides instructions for authors who

advertisement

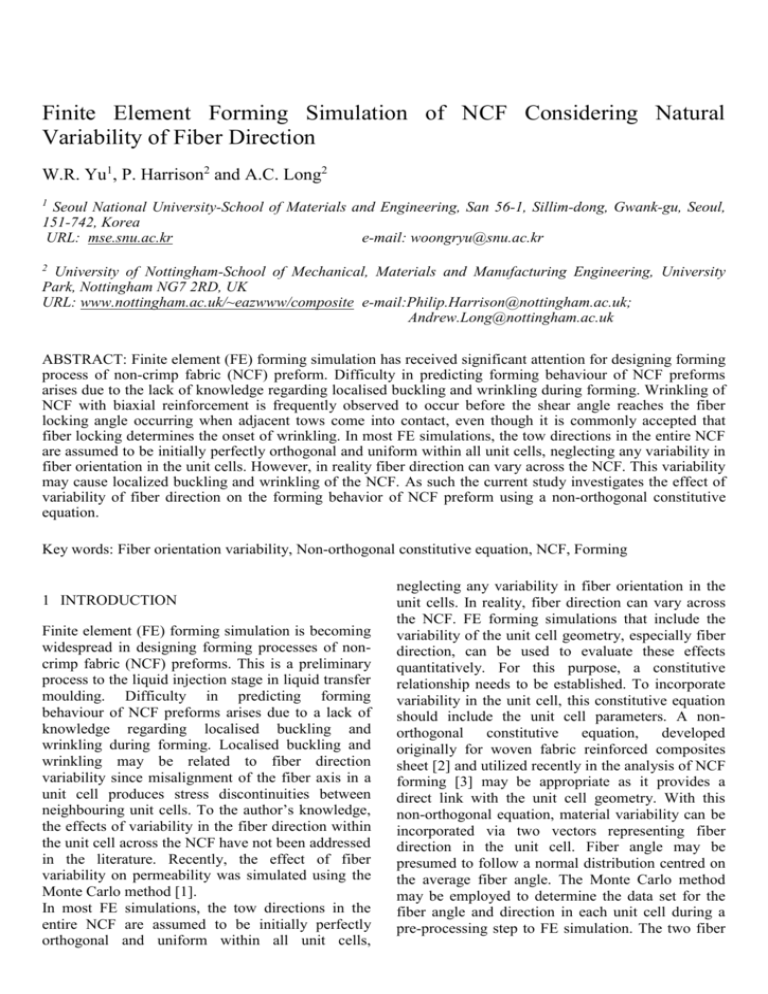

Finite Element Forming Simulation of NCF Considering Natural Variability of Fiber Direction W.R. Yu1, P. Harrison2 and A.C. Long2 1 Seoul National University-School of Materials and Engineering, San 56-1, Sillim-dong, Gwank-gu, Seoul, 151-742, Korea URL: mse.snu.ac.kr e-mail: woongryu@snu.ac.kr 2 University of Nottingham-School of Mechanical, Materials and Manufacturing Engineering, University Park, Nottingham NG7 2RD, UK URL: www.nottingham.ac.uk/~eazwww/composite e-mail:Philip.Harrison@nottingham.ac.uk; Andrew.Long@nottingham.ac.uk ABSTRACT: Finite element (FE) forming simulation has received significant attention for designing forming process of non-crimp fabric (NCF) preform. Difficulty in predicting forming behaviour of NCF preforms arises due to the lack of knowledge regarding localised buckling and wrinkling during forming. Wrinkling of NCF with biaxial reinforcement is frequently observed to occur before the shear angle reaches the fiber locking angle occurring when adjacent tows come into contact, even though it is commonly accepted that fiber locking determines the onset of wrinkling. In most FE simulations, the tow directions in the entire NCF are assumed to be initially perfectly orthogonal and uniform within all unit cells, neglecting any variability in fiber orientation in the unit cells. However, in reality fiber direction can vary across the NCF. This variability may cause localized buckling and wrinkling of the NCF. As such the current study investigates the effect of variability of fiber direction on the forming behavior of NCF preform using a non-orthogonal constitutive equation. Key words: Fiber orientation variability, Non-orthogonal constitutive equation, NCF, Forming 1 INTRODUCTION Finite element (FE) forming simulation is becoming widespread in designing forming processes of noncrimp fabric (NCF) preforms. This is a preliminary process to the liquid injection stage in liquid transfer moulding. Difficulty in predicting forming behaviour of NCF preforms arises due to a lack of knowledge regarding localised buckling and wrinkling during forming. Localised buckling and wrinkling may be related to fiber direction variability since misalignment of the fiber axis in a unit cell produces stress discontinuities between neighbouring unit cells. To the author’s knowledge, the effects of variability in the fiber direction within the unit cell across the NCF have not been addressed in the literature. Recently, the effect of fiber variability on permeability was simulated using the Monte Carlo method [1]. In most FE simulations, the tow directions in the entire NCF are assumed to be initially perfectly orthogonal and uniform within all unit cells, neglecting any variability in fiber orientation in the unit cells. In reality, fiber direction can vary across the NCF. FE forming simulations that include the variability of the unit cell geometry, especially fiber direction, can be used to evaluate these effects quantitatively. For this purpose, a constitutive relationship needs to be established. To incorporate variability in the unit cell, this constitutive equation should include the unit cell parameters. A nonorthogonal constitutive equation, developed originally for woven fabric reinforced composites sheet [2] and utilized recently in the analysis of NCF forming [3] may be appropriate as it provides a direct link with the unit cell geometry. With this non-orthogonal equation, material variability can be incorporated via two vectors representing fiber direction in the unit cell. Fiber angle may be presumed to follow a normal distribution centred on the average fiber angle. The Monte Carlo method may be employed to determine the data set for the fiber angle and direction in each unit cell during a pre-processing step to FE simulation. The two fiber 2 NATURAL VARIABILITY 2.1 Experimental observation Fiber angle distribution has been investigated for an unsheared 45 non-crimp glass fiber fabric, Formax FGE106 [4]. The angle between the fiber direction and the 90 direction of the fabric, which is expected to be half the fiber angle, , has been experimentally determined at various position on both faces of the fabric using photographic imaging and digital image analysis. Statistical evaluation of the data indicates that can be described by a normal distribution with a mean of 42.7 and a standard deviation of 5.6 . Figure 1 compares the histogram of the observed angle distribution with the corresponding normal distribution indicating satisfactory agreement with a correlation coefficient R 2 0.955 . As shown in figure 1, the fiber orientation may deviate from the orthogonal position by up to 10 when a 95% probability is considered. This variation is significant, resulting in variable mechanical properties, such as shear stiffness. Regarding the effect of fiber direction variability, it is reported that the application of pre-tension helps to improve reproducibility of picture-frame shear test [5]. This is possibly caused by the pre-tension aligning the tows straightly in the preform and thus removing fiber directional variability. 0.4 0.35 Normal distribution Experimental data 0.3 Probability vectors are then used in calculating the stiffness matrix and updated to create a new matrix as deformation proceeds due to stamping. Besides fiber directional properties, shear properties also need to be varied according to the variability of the fiber direction. Shear properties are characterized by either picture frame or bias extension tests that record shear force vs. shear angle. For such tests, the shear angle is defined as an angle sheared from the original fiber angle. Thus, because of the variability in the fiber direction, the pre-shear stiffness inherent in the un-deformed NCF sheet will vary between elements. This initial variation in element stiffness is determined from the shear force versus angle experiments. In this way, effects of variation in the fiber direction within unit cells are investigated virtually. 0.25 0.2 0.15 0.1 0.05 0 22.5 27.5 32.5 37.5 42.5 47.5 52.5 57.5 62.5 Fibre Angle (degrees) Fig. 1. Half fiber angle of a NCF preform: histogram of experimental data and corresponding normal distribution [4]. 2.2 Incorporation of variability into simulation The aim of the current study is to investigate the effect of fiber direction variability on the forming behavior of NCF preforms. The variability results from the fabric attribute. It is referred to here as ‘natural’ variability because the variability is introduced naturally during production, manipulation, storing, and handling of the preform. Since it is difficult to predict precisely where fiber angle variation occurs in the preform, we employed a statistical method to impose fiber direction variability in the NCF specimen. The statistical method is based on the assignment of fiber angle to each material point using a random variable as follows. 2erf 1 (2D 1) 0 (1) Here, is fiber angle determined from normal distribution of mean fiber angle ( 0 ) and standard deviation ( ) through uniformly distributed random values D on the interval (0, 1). Using equation (1), fiber angle can be assigned to any material point, i.e. to the Gaussian integration points of the finite elements that are used to approximate the fabric preform. Once the fiber angle is given, the fiber orientation for the two tows needs to be determined. For a given fiber angle, the fiber orientations are described by two vectors e warp and e weft . Naturally the fiber direction, e.g., e warp , can be misaligned from global fiber direction which represents 45 fiber axis in NCF preform when not considering variability. The misalignment has been constrained to lie within (90 ) / 2 from the global fiber direction. The actual misalignment ( ) can be determined using equation (2) as with the fiber angle case in equation (1). (2D 1)(90 ) / 2 (2) As a result, a fiber direction ( e warp ) can be placed randomly between (90 ) / 2 to (90 ) / 2 from global fiber direction. The weft direction ( e weft ) is then obtained by rotating the warp direction through the given fiber angle. Since, in this approach, the fiber directions and angle are randomly assigned to the material point of the preform, the continuity of the fiber path is not preserved between adjacent elements. More study should be focused on the compatibility of the fiber orientation between adjacent elements to avoid unrealistic fiber paths. This will be discussed in a future study. The fiber orientation is crucial to determining the constitutive equation. Since fiber orientation is not initially orthogonal when variability is considered, a non-orthogonal constitutive equation is indispensable to simulating the forming behavior of NCF. Material properties for the non-orthogonal equation consist of structural parameters, including fiber orientation and mechanical properties such as shear stiffness. Considering fiber direction variability, the structural parameters remain unchanged except the fiber direction vector. As for shear resistance, the question of whether the misalignment of the fiber direction invokes preshear stress must be decided. In this study, fiber angle variation is regarded as a pre-sheared fiber angle, thus the material point has a pre-shear stress. The size of this stress can be determined from shear force - shear angle data using the shear constitutive equation. Details about this pre-stress treatment are omitted here. 3 RESULTS AND DISCUSSION Prior to evaluating the effect of natural variability, mesh sensitivity needs to be investigated because the current approach to considering fiber direction variability relies on the assignment of fiber angle to material points using random variable, i.e., as the number of elements increase, the fiber angle variation follows a normal distribution more closely. Two simulations have been performed for bias extension and picture-frame shear tests. For pure shear deformation, as in the picture-frame shear test, mesh sensitivity seems negligible. However, the simulations of bias extension test show mesh sensitive behavior due to the combination of both pure shear and tensile deformation. Thus, for the forming simulation of NCF including fiber direction variability, mesh sensitivity should be investigated also. However we discuss simulation results in this paper without presenting such mesh sensitivity studies. To investigate the effect of fiber direction variability, a forming example is chosen from a collaborative benchmark forum for woven composite forming [6]. The forming tools are constructed to stamp textile preform or prepreg into a half cylindrical shell with double dome ends. Tool geometry and forming condition are detailed in [6]. The NCF preform used for this simulation is a tricot-stitched biaxial fabric. Its material properties, including shear resistance, can be found in [3]. Fig. 2. Fiber angle variation applied to material points of a NCF preform for double dome forming simulation. Figure 2 shows the fiber angle distribution of a NCF preform, determined using equation (1) by assuming a normal distribution with a mean of 90 and a standard deviation of 1 . The fiber angle variability is incorporated into the non-orthogonal constitutive equation using a user material subroutine in ABAQUS/Explicit. Shell elements (S3) are used to approximate the NCF preform. To compare the effect of fiber angle variation on the forming behavior, the first simulation was performed for a zero-variability case. Figure 3 (a) shows a formed shape when the global fiber orientation is placed on the 1 and 3 axes. In this simulation a blank holder force was not applied but instead clearance between the blank holder and die was maintained during the simulation in order to maintain a preform thickness. In the simulation, wrinkling is observed at six parts in both fiber directions on the flange part of the preform. When fiber angle variability is incorporated, the formed shape shows wrinkling behavior similar to the zero-variability case but more localized wrinkling was propagated along the line where the major wrinkling occurs as shown in Figure 3(b). More theoretical analysis should be performed to conclude the main causes of such localized wrinkling; however tentatively it can be thought that the localized buckling may be caused by incompatible material properties through thickness due to the fiber angle variation. variability is an important factor in determining the onset of localized wrinkling, however, systematic research for incorporating fiber angle variability in NCF preforms needs to be performed in order to support the findings. (a) (a) (b) Fig. 4. The effect of fiber direction variability on the fiber angle distribution: (a) zero-variability (b) variability ( 0 90, 1 ) REFERENCES 1. (b) Fig. 3. The effect of fiber direction variability on the formed shape: (a) no variability (b) variability ( 0 90, 1 ) Fiber angle distribution is also compared for the two cases to investigate its role in wrinkling. As shown in figure 4(a), the fiber locking angle may not be the crucial factor in determining wrinkling behavior because wrinkling is not observed in locations of severe shear deformation. It is clear from figure 4(b) that even though fiber locking is not an absolute factor for the wrinkling, fiber direction variability plays a role in the localized wrinkling. 4 CONCLUSION Fiber angle and direction variability are incorporated into forming simulations using a statistical method. From forming simulations it is shown that fiber 2. 3. 4. 5. 6. A. Endruweit, A.C.Long, F.Robitaille, C.D.Rudd, Dependence of permeability variations on the textile structure. In: Proc. ECCM'11 From nano-scale interaction to Engineering structures, Rhodes in Greece (2004). W.R. Yu, F. Pourboghrat, K. Chung , M. Zampaloni and T.J. Kang, Non-orthogonal constitutive equation for woven fabric reinforced thermoplastic composites, Comp Part A-App S, 33, (2002), 1095-1105 W.R.Yu, P. Harrison and A.C. Long, Finite Element Forming Simulation for Non-crimp Fabrics using a NonOrthogonal Constitutive Equation, Comp Part A-App S, accepted, (2004) R.A. Andrews, Real life process simulation-Predicting the range of outcomes during composites manufacturing, BEng Individual Project Report, University of Nottingham (2003). A.C.Long, B.J.Souter, F.Robitaille, C.D.Rudd, Effect of fiber architecture on reinforcement fabric deformation, Plast Rubber Compos, 2/31, (2002), 87-97. http://www.gtwebsolutions.com/nwbenchmark/index.php