term project (hw8)

advertisement

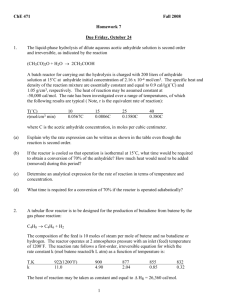

Fall 2010 ChE 471 Homework No. 8 (FINAL VERSION) (due Friday, November 12) 1. The reaction between sodium thiosulfate and hydrogen peroxide in dilute aqueous solution is irreversible and second order in thiosulfate. The rate constant is the following function of temperature: 18300 14 , cm3 /(mol)(s) k 6.85 x 10 exp Rg T Reaction stoichiometry indicates that 2 moles of H2O2 react with one mol of Na2S2O3. The heat of reaction at 25˚C is HR = -131,000 (cal/mol). The universal gas constant is Rg = 1.987 (cal/mol ˚C). Kearns and Manning's (AIChE J., 15, 660 (1969)) experimental studies in a continuous flow stirred-tank reactor (CSTR or MFR) included the following conditions: Reactor volume = 2790 cm3 Feed temperature = 25˚C Feed rate = 14.2 cm3/s Consider adiabatic operation and feed concentrations of 2.04 x 10-4 (mol/cm3) and 4.08 x 10-4 (mol/cm3) of thiosulfate and hydrogen peroxide, respectively. What is the conversion and temperature in the reactor effluent? 2. A tubular-flow reactor (assume plug flow) is to be designed for the production of butadiene from butene by the following reaction in the gas phase: C4H8 C4H6 + H2 The composition of the feed is 10 moles of steam per mole butene and no butadiene or hydrogen. The reactor operated at 2 atmospheres pressure with an inlet (feed) temperature of 1200˚ F. The reaction rate follows a first-order, irreversible equation for which the rate constant k as a function of temperature is: T(K) 922 (1200˚F) k 11.0 900 877 4.90 855 2.04 832 0.85 0.32 (k = mol butene reacted/(h) (liter) (atm)). The heat of reaction may be taken as constant and equal to HR = 26,360 (cal/mol). Similarly the specific heat of the system may be regarded as constant and equal to 0.5 Btu/lb ˚R. 1 3. A. What would be the volume required for a conversion (of butene) of 20% if the reactor were operated isothermally at 1200˚F with a butene-plus-steam feed rate of 22 lb mol/h? B. It is desired to determine the conversion as a function of reactor volume (ft3) for adiabatic operation if the feed rate is 2.0 lb mol of butene per hour and 20 lb mol of steam per hour. Demonstrate your ability to solve this type of problem by calculating the reactor volume for conversions (of butane) of 10% and 20%. What changes in operating conditions could be employed to reduce the volume required for a given conversion? As noted in class for exothermic, reversible reactions increasing the temperature reduces the maximum (equilibrium) conversion but increases the forward rate. To obtain the maximum conversion a high temperature is needed at low conversions (where the reverse reaction is unimportant) and a lower temperature at higher conversions. Consider a reversible first-order reaction A B for which, at 298 K, G˚298 = - 2500 cal/mol H˚298 = - 20,000 cal/mol (heat of reaction) The reaction mixture is an ideal liquid solution (constant density) at all temperatures. (a) Assuming that H˚ is constant, plot a curve of the equilibrium conversion vs. temperature from 0 to 100˚C. (b) If the forward-rate constant is k = 5 x 108 e-12,500/RgT min-1 ; Rg = 1.987 (cal/mol ˚C) determine the conversion in the effluent from an isothermal tubular-flow reactor for which the volumetric feed rate is 100 liters/min and the volume is 1500 liters. Calculate the conversion for a series of temperatures from 0 to 100˚C and plot the results on the figure prepared for part (a). (c) Suppose that the maximum permissible temperature is 100˚C and the concentration of A in the feed stream is 2 (mol/liter) (the feed contains no B). Determine the maximum conversion obtainable in the reactor of part (b) if the temperature can be varied along the length of the reactor. First prepare curves of net rate vs. temperature at constant conversion for several conversion levels. Then plot the optimum temperature profile, first as temperature vs. conversion and then as temperature vs. V/Q. d) Plot the heat to be removed (added) from each 10th of the rector volume for part c). 4. Consider the same reaction system, rate equation, feed rate, and composition as in Problem 3. The reaction is to be carried out in two-stirred tank reactors, each with a volume of 750 liters. What should be the temperature (within the range 0 to 100˚C) in each reactor in order to obtain the maximum conversion in the effluent from the second reactor? The graphical method for multi-stirred tank reactors may be helpful. 2 5. Consider a first order reaction (A P) with the rate - RA = 4.2 x 108 e-30,000/RT CA mol m3 s with the activation energy given in calories per mol. The heat of this highly exothermic reaction is HR = -150,000 cal/mol and the heat capacity of the mixture is Cp = 300 cal/m3˚K We run this reaction in a wall cooled tubular (plug flow) reactor of diameter of 2.5 cm.. The inlet and wall temperature are To = Tc = 640˚K. The overall heat transfer coefficient is estimated to be U = 25 (cal/mol2 s˚K). What is the maximum reactant feed concentration that we can use and still avoid hot spots in the reactor? 6. 7. Reactant A that undergoes the reaction considered in problem 1 has been routinely stored in cylinders at concentration of 20 mol/m3 and stocked in a storage area with temperature at 25˚C. The reactant often was kept for years at such conditions in the storage area. a) What is the time to explosion i.e the time to the point of no return at To = 25 + 273 = 298˚ K for this reactant? Is storage for up to 5 years at 25˚C safe? b) A fire broke out and heated our storage area with the cylinders with A to 200˚C (473˚K). How long a time do you have to bring the fire under control and cool the cylinders before the point of no return is reached? Hint: Use the data that you need for this reaction system from problem 1. Recall the analogy between adiabatic plug flow and adiabatic batch reactor and therefore the analogy between safe * and safe t*. The following irreversible second order gas phase reaction 2A = R + S is to be conducted in a wall cooled tubular (plug flow) reactor. Reaction rate is given by: RA mol A 15 25,000/ RT 2 CA 3 1.5 x 10 e m s where E = 25,000 cal/mol is the activation energy and CA 3 mol A is reactant m3 concentration. Other pertinent data include the heat of reaction HRA 20, 000 cal/mol A: volumetric heat capacity of the reaction mixture C p = 600 (cal/m3 ˚K); coolant and feed temperature To = Tc = 300˚K; overall wall heat transfer coefficient cal ; feed reactant concentration CAo = 20 (mol A/m3). U = 50 2 m K s a) Would 2" diameter (dt = 0.0508 m) tubes be safe to use? b) If the coolant failed what is the potential maximum temperature rise in this reactor? Is it dangerous? If the reactor became adiabatic and the gas velocity is 20 (m/s) and the reactor length is 5 meters would the resulting avoid the maximum rate of the temperature * rise to occur on the reactor i.e is ? 4