2011 Fall Exam #3

advertisement

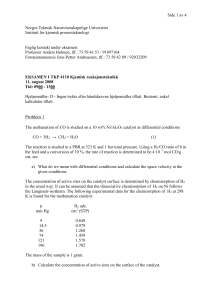

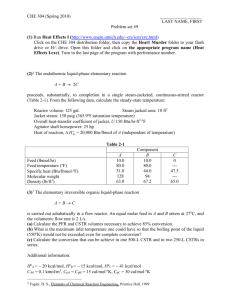

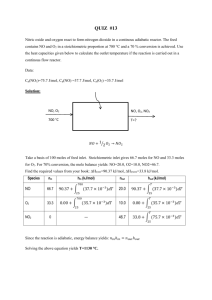

Fall 2011 ChE 471 Exam 3 (closed book and closed notes, three crib sheets allowed) 1. A first order irreversible reaction A products (– RA = 2.5 CA (mol/L min)) is conducted in a flow reactor at constant temperature. The reactor volume is V = 200 L and it processes 300 L/min of the feed at CAo = 1 (mol/L). a) What conversion would we obtain if this reactor behaved as a: i) CSTR, ii) PFR? You perform an impulse tracer experiment on your actual reactor and obtain the following tracer response to an instantaneous injection of mt = 6000 mg of tracer C 20 mg L t(min) 1 b) c) d) e) 2. Run 1 Run 2 2 Is the mass balance preserved for the tracer experiment and if so, what is the E– curve? Is all the volume of the system accessible to flow? Model the observed E-curve with an appropriate number of stirred tanks in series and predict conversion based on that model. How can you predict most accurately the conversion that will be achieved in your reactor with the E-curve obtained from the above tracer experiment and what is that conversion? A first order irreversible catalytic reaction A → P is carried out at isothermal conditions, in absence of all external transport effects, in a stirred basket reactor on two different size catalyst pellets. The pellets are spherical. The catalyst activity and pore structure of the pellets are identical. Therefore the kinetic rate constant and effective diffusivity are identical in pellets of both sizes. The temperature, pressure and bulk reactant concentration are identical in both runs. The following data are obtained. Pellet Diameter (cm) 1.0 0.1 1 Observed Rate x 105 (mol/cm3cat.s) 3.0 15.0 Estimate the Thiele modulus and effectiveness factor for each particle. Are internal diffusion effects pronounced in each pellet size? What pellet diameter is needed to completely eliminate internal diffusion resistance at the temperature of these experiments (i.e. 1). a) b) 3. What can you tell about the controlling resistance (film, diffusion, kinetic) and activation energy for a 1-st order catalytic reaction based on the data below obtained in a small packed bed reactor with large gas recycle. Therecycle rate is always sufficiently high to achieve CSTR behavior. Changes in recycle rate above the high value affect and further improve the external mass transfer coefficient. Isothermal conditions prevail in the reactor during each run and particle temperature equals the exit gas temperature. Constant density can be assumed. (No need to worry about units for the data below, they are consistent. Note that temperature is reported in degrees centigrade). Run 1 2 3 4 Volumetric Flow Rate 5 2 8 9 CA feed CA exit 5 4 2 3 1 1 1 1 Mass of Catalyst 10 6 4 9 Pellet Diameter 1 2 2 2 Recycle Rate high highest highest high Temp (oC) 320 320 360 360 a) What is the dominant resistance? b) What is the activation energy? Report it in (cal/mol). Hence R= 1.987 (cal/mol K) Document and explain your answers. 4. A secretary spilled coffee all over the flow chart for your process line in which A isomerizes to B on a solid catalyst in packed bed adiabatic reactors. However, the conversion-temperature diagram has been saved and is shown below. Your boss asked you to reconstruct the process flow chart from that diagram. Show: a) The molar flow rates of all streams. (If recycle is involved calculate all recycle ratios). b) The location and heat duty of all heat exchangers, and indicate whether they add or remove heat and report the rate of heat removal or addition in calories per hour. Data: Molar feed rate Fo = 1,000 (mol/h), Cp = 300 (cal/mol K)= ρCP/CA0; H RA 26,000(cal / mol) (Hence, the slope of adiabatic lines ab and cd is Cp/(-ΔHRA) To avoid the ambiguity in reading the attached graph, the coordinates (T, xA) of the points needed for your calculations are given here: b(350, 0.4); e(365, 0.4); f(305, 0.4). In addition note that conversion at point a is 0.2; at point c is 0.5; and at point d is 0.8. 2 1.0 d 0.8 0.6 xA c 0.4 b f 0.2 e a g 350 400 To = 300K 3 T(K)